1 overview of the “3 points” mode – IAI America ERC2 User Manual

Page 107

6. Operation in the “3 Points (Air Cylinder)” Mode

84

6. Operation in the “3 Points (Air Cylinder)” Mode

6.1 Overview of the “3 Points” Mode

This mode provides a control method adjusted to that of an air cylinder by assuming that the actuator is used as an air

cylinder.

The key differences between the ERC2 and an air cylinder are summarized below. Perform proper control by referring

to this table.

Item

Air cylinder

ERC2

Drive method Air pressure supplied via

electromagnetic valve

control

Ball screw/timing belt driven by a motor

Target position

setting

Mechanical stopper

(including shock absorber)

Desired coordinates are entered in the [Target position] field of the

position table.

The coordinates can be typed in from the number keys on the PC

keyboard or on the teaching pendant, or set directly by moving the

actuator to the target position.

Target position

detection

An external detection

sensor, such as a reed

switch, is installed.

Determined based on the internal coordinates provided by the position

information from the position detector (encoder).

Accordingly, external detection sensor is not required.

Speed setting Adjusted by a speed

controller.

A desired feed speed is entered in the [Speed] field of the position table

(unit: mm/sec).

Note that the rated speed is automatically set as the initial value.

Acceleration/

deceleration

setting

Determined in accordance

with the load, supplied air

volume, as well as the

performance of the speed

controller and

electromagnetic valve.

A desired acceleration/deceleration is entered in the

[Acceleration/deceleration] field of the position table (unit: 0.01 G).

(Reference) 1 G = Gravitational acceleration

Note that the rated acceleration/deceleration is automatically set as the

initial value.

Since the acceleration/deceleration can be set in fine steps, a gradual

acceleration/deceleration curve can be programmed.

Position check

upon power

ON

Determined by an external

detection sensor, such as

a reed switch.

Immediately after the power is turned on, the controller cannot identify the

current position because the mechanical coordinates have been lost.

Therefore, when the first movement command is issued after the power

has been input, the controller will automatically perform home return

before moving the actuator to the target position.

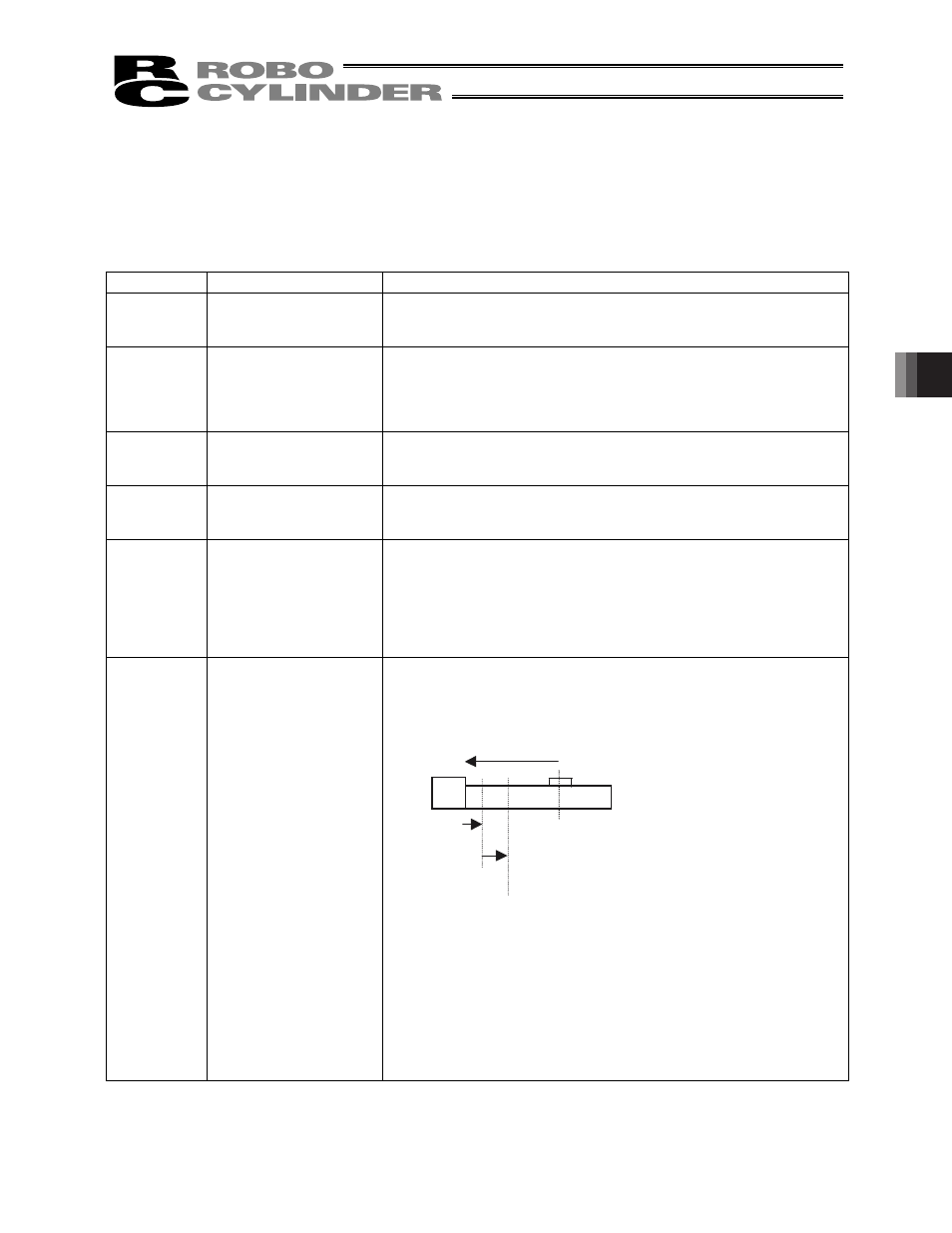

[1] The actuator moves at the home return speed toward the mechanical

end on the motor side.

[2] The actuator hits the mechanical end and turns back, and then stops

temporarily at the home position.

[3] The actuator moves to the target position at the speed specified in

the [Speed] field of the position table.

(Note) Pay attention not to allow any obstacle in the travel path of

the actuator during home return.

Home

position

[1]

[2]

[3]

Target position

Power is turned

on here.