IAI America ERC2 User Manual

Page 128

7.

O

pe

ra

tio

n

in

th

e

“8

P

oi

nt

s”

a

nd

“

16

P

oi

nt

s”

M

od

es

<

Pr

ac

tic

al

O

pe

ra

tio

n>

105

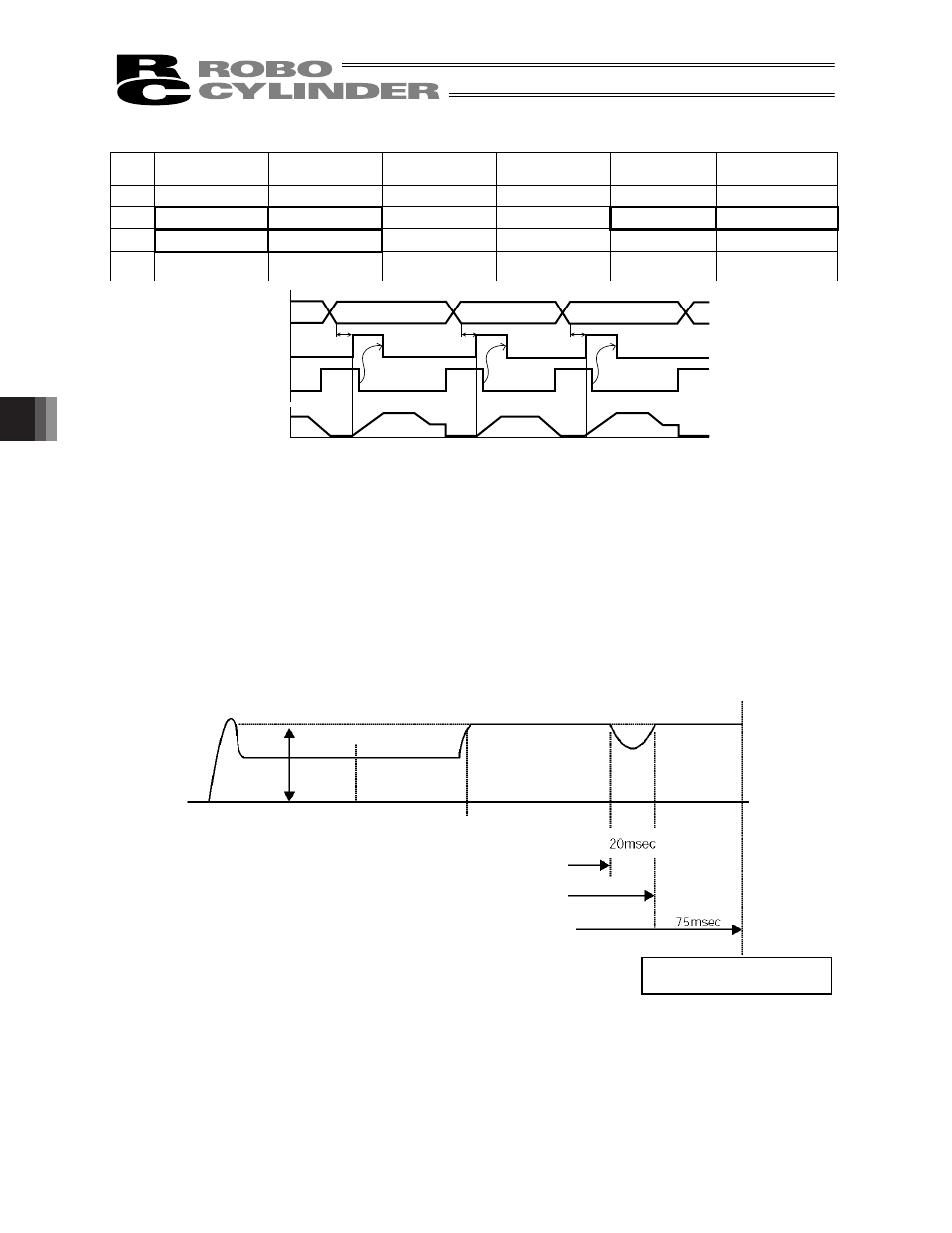

Position-data table (Field(s) within thick line must be entered.)

No.

Position

[mm]

Speed

[mm/s]

Acceleration

[G]

Deceleration

[G]

Push

[%]

Positioning band

[mm]

0

*

*

*

*

*

*

1

280.00

200.00

0.30

0.30

50

15.00

2

40.00

100.00

0.30

0.30

0

0.10

x

x

x

T1:

6 msec or more; time after selecting/entering a command position until the start input turns ON

(The scan time of the host controller must be considered.)

Each command position must be input after the position complete output has turned ON for the movement to the

previous position.

z

Conditions for determining completion of push & hold operation

Push & hold operation is deemed to have completed upon elapse of the time set by parameter No. 6 (Push

completion judgment time) after the motor current reached the current-limiting value set in the “Push” field of the

position table.

Set an appropriate value by considering the material and shape of the work part, and so on.

The minimum setting unit is “1 msec,” while the maximum value is “9999 msec.” The factory setting is “255 msec.”

(Note) The chart below explains how completion of push & hold operation is determined if the work part shifted

during the judgment and the current has changed as a result, based on a judgment time of 255 msec.

If the motor current remains at or above the push current for 200 msec and then drops below this level for 20 msec,

the count will decrease by 20. When the push current is reached again thereafter, counting will start from 180. If the

motor current remains at or above the push current for 75 msec, the count will increase to 255 and thus push & hold

operation will be deemed to have completed.

In total, 295 msec was required for the judgment.

Position 1

Position 2

Position 1

Command position

Start

Position complete

Actuator movement

T

1

T

1

T

1

Completion of push & hold operation

Completion of push & hold operation

Push current

Starting position

Target position

Counting starts.

The count increases to 200.

The count decreases to 180.

The count increases to 255.

Push & hold operation is

deemed to have completed.

S

pe

ed