Maintenance and inspection, 1 inspection items and schedule, 2 visual inspection of appearance – IAI America ERC2 User Manual

Page 167: 3 cleaning

10. Maintenance and Inspection

144

10. Maintenance and Inspection

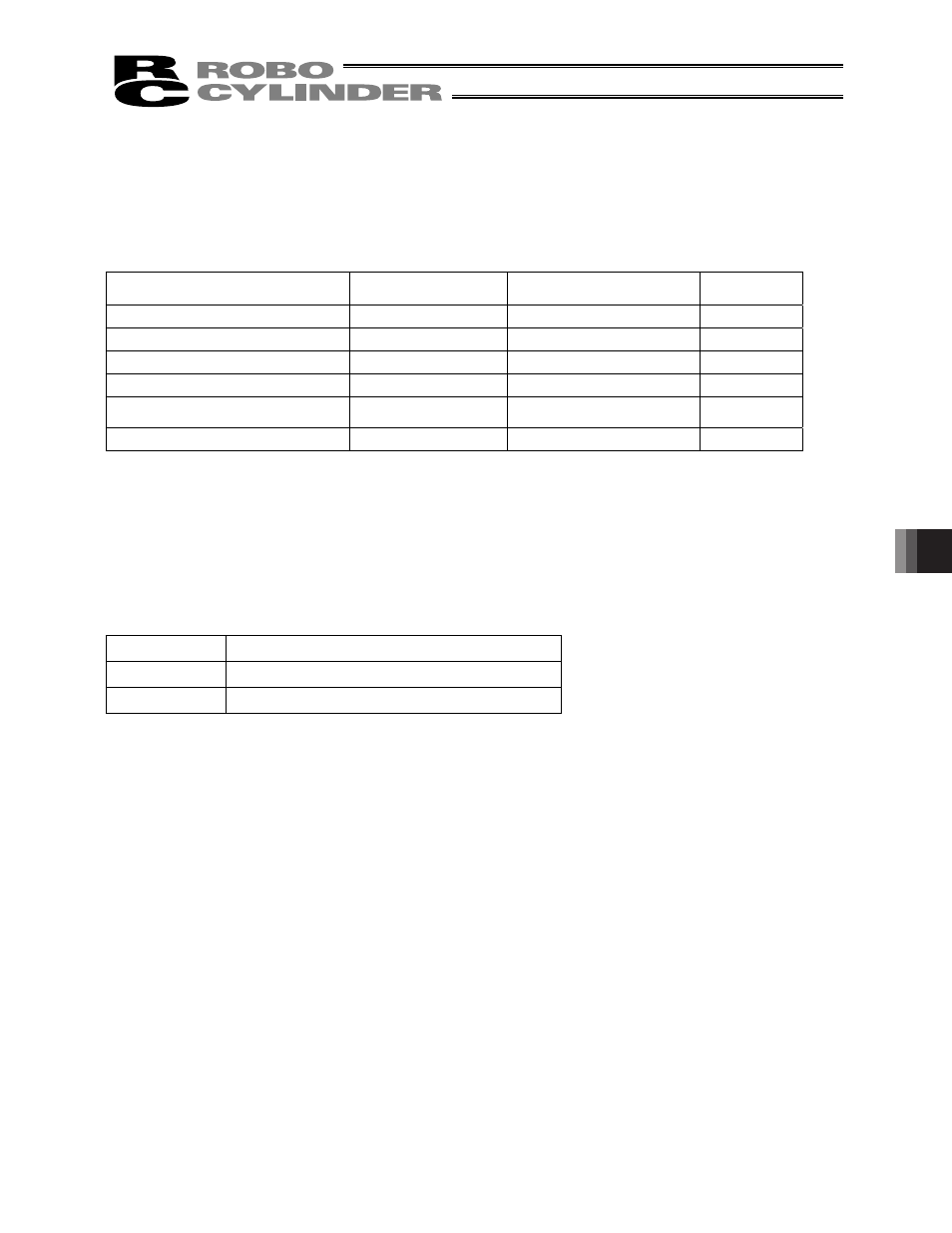

10.1 Inspection Items and Schedule

Perform maintenance and inspection per the schedule specified below.

This schedule assumes eight hours of operation a day. Shorten the inspection intervals if the utilization is higher, such

as when the actuator is operated continuously day and night.

Visual inspection of

appearance

Greasing

Model

Start-up inspection

{

After 1 month of operation

{

After 3 months of operation

{

{

(Rod slide surface)

Rod type

*1

Every 3 months thereafter

{

{

(Rod slide surface)

Rod type

*1

After 3 years of operation or 5,000

km of moving distance

{

{

(Guide/ball screw)

Slider type

*2

Every 1 year thereafter

{

{

(Guide/ball screw)

Slider type

*2

*1 With a rod-type actuator, grease the rod slide surface if the surface is found dry at the start-up inspection or

every three months.

*2 With a slider-type actuator, grease the guide and ball screw as necessary by considering the use environment,

condition, etc.

10.2 Visual Inspection of Appearance

Check the following items in the visual inspection:

Actuator

Loose actuator-mounting bolts, etc.

Cables

Damage, connector coupling

Overall

Noise, vibration

10.3 Cleaning

x

Clean the exterior as necessary.

x

Wipe off dirt using a soft cloth, etc.

x

Do not blow compressed air at high speed. Doing so may cause dust to enter the actuator through gaps.

x

Do not use petroleum solvent, since it will damage the resin and coated surfaces.

x

To remove significant soiling, wipe the area gently using a soft cloth, etc., moistened with neutral detergent.