Siemens SINUMERIK 840C User Manual

Page 637

Meas.

parameters

09.95

Siemens AG 2001

All Rights Reserved

6FC5197–

j

AA50

9–16

SINUMERIK 840C (IA)

9.2.4

Speed control loop (axis and spindle) – measurement parameters

(4 basic settings – as from SW 3)

Overview of

The types of measurement available depend on the type of drive used. Various

measurement types

variables can be measured depending on the type of measurement selected.

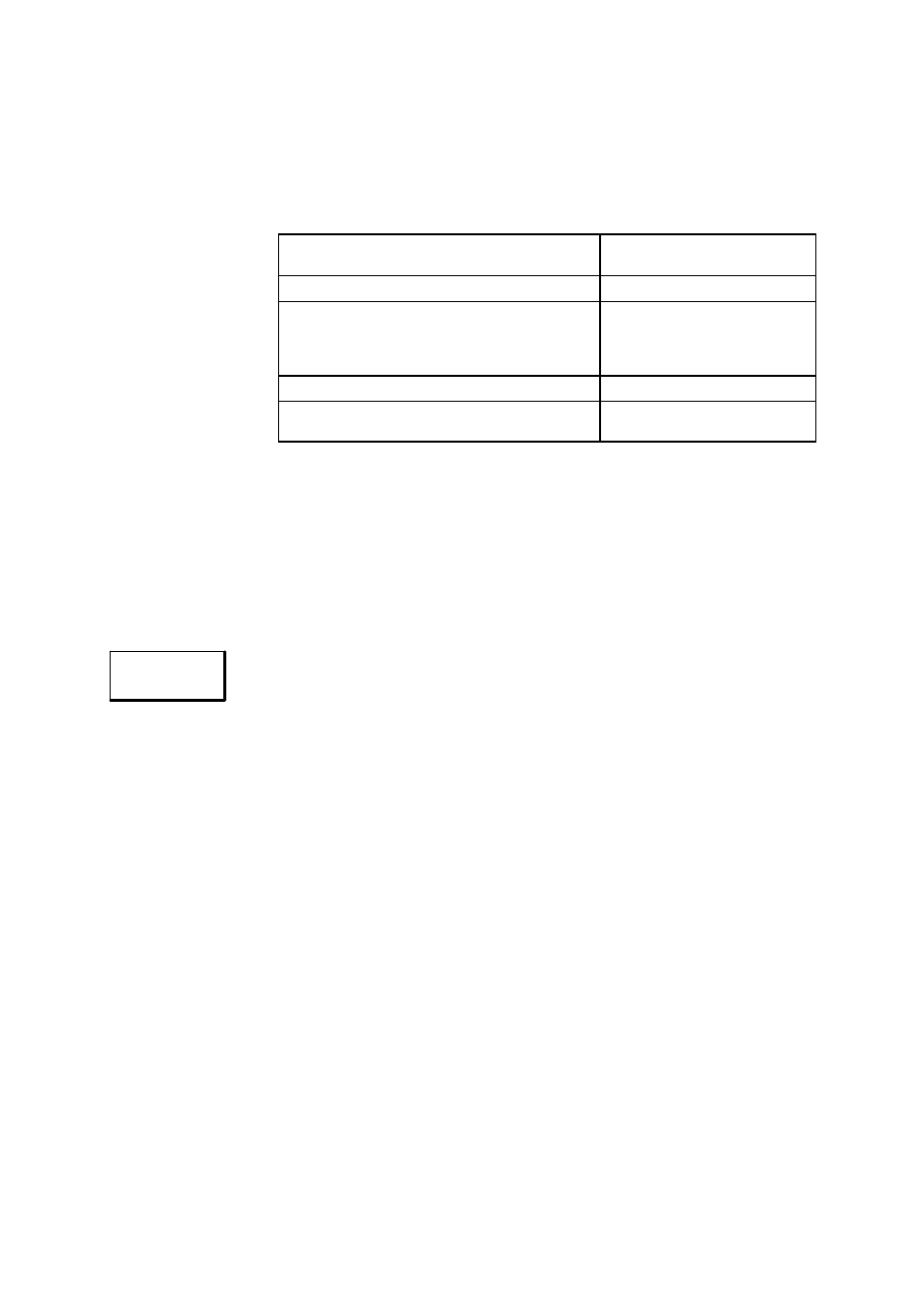

Type of measurement

Measured quantity Speed

actual value

Reference frequency response

analog / 611D

Interference frequency response (up to

SW 4

Mechanical frequency response n

act

/Iq

act

(as from SW 5)

611D FDD (SW 3)/

611D (SW 4)

Setpoint step change

analog / 611D

Disturbance step change

611D FDD (SW 3)/

611D (SW 4)

Note

If the selected measurement cannot be carried out with the installed drive, the

dialog box 160007 Measurement/drive-type combination not allowed appears

when the Start softkey is selected.

D

1st measurement type: Reference frequency response

The reference frequency response measurement determines the transient re-

sponse of the speed control loop. The response range should be as wide as pos-

sible and without resonance. It may be necessary to install stop or low-pass

(611D) filters. Particular care must be taken to prevent resonance within the

speed controller limit frequency range.

You can select the menu with the parameters for measuring the speed control

loop with this softkey.

Notes

You enter the measurement parameters in the selected display. These parame-

ters are managed internally as configuration data rather than machine data, i.e.

they initialized when the machine runs up. Data can be input in two different

ways:

S

Manual input

S

Input by loading of an existing, complete data set with the aid of file functions

The measurement of the MSD speed control loop frequency response is carried

out with respect to the position control only with SW 3 and therefore makes allo-

wance for system-related transfer times between the position and speed control

loops.

Measurement

S

Amplitude

parameter settings

This parameter determines the magnitude of the test signal amplitude.

(see Section “Signal

It should not be more than a few (approx. 1–2) motor rpm for the 1st basic

waveforms

setting (frequency reference response).

of function generator”)

S

Offset

The measurement requires a small speed offset of a few motor revolutions

per minute. The offset value must be set higher than the amplitude value.

9 Drive Servo Start-Up Application (as from SW 3)

9.2.4 Speed control loop (axis and spindle) – measurement parameters (4 basic settings – as from SW 3)

07.97