Siemens SINUMERIK 840C User Manual

Page 1067

12 Functional Descriptions

09.95

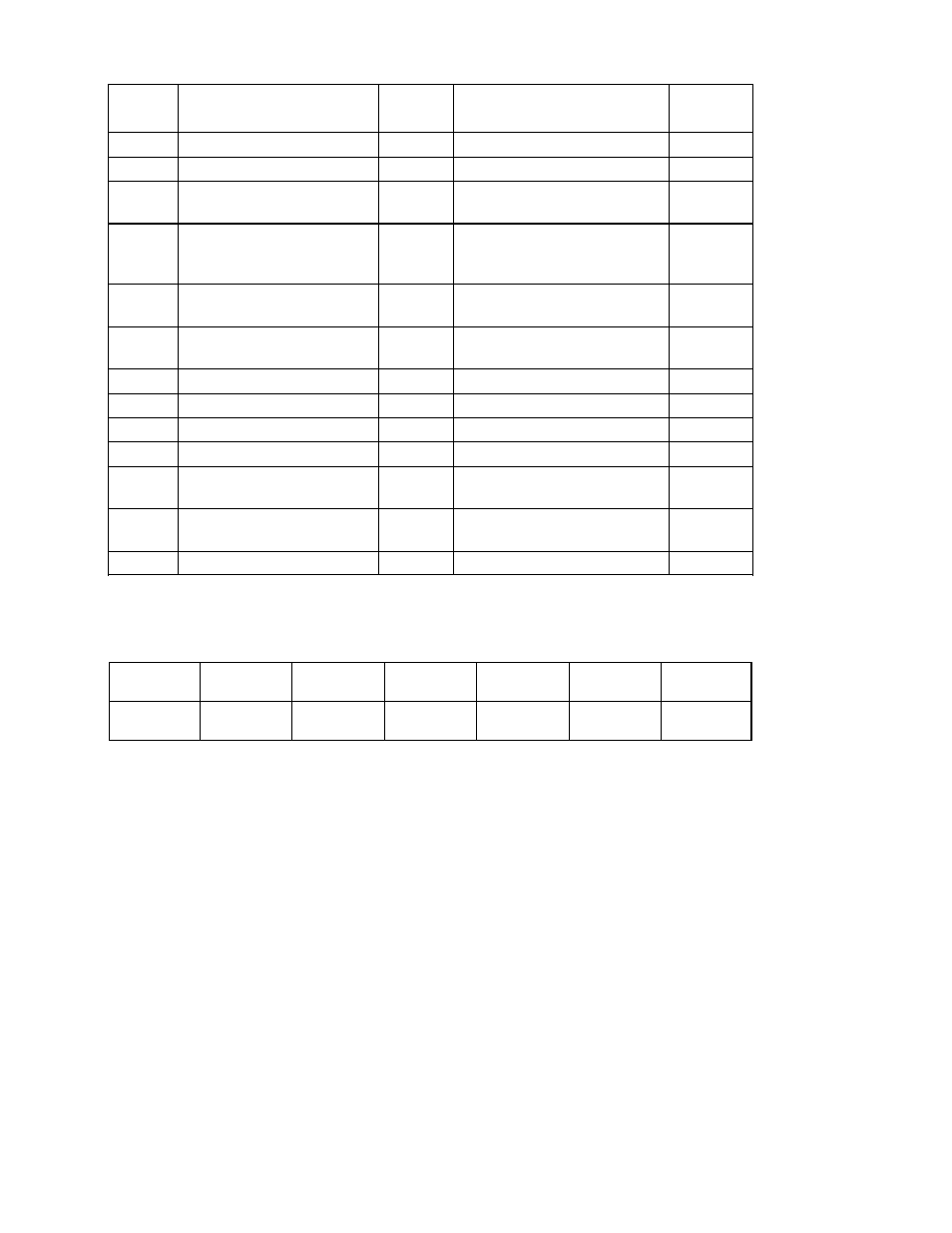

12.28.8 Overview of function identifiers and configuring parameters (DB 2, DR 2 ... DR 6)

Signal

number

Meaning

Data

format

1)

Unit

Attribute

5

Part setpoint

SL

0.01 % of max. load speed

3)

Read

6

Synchronism deviation

SL

UMS

Read

7

Angular offset (mech.

coupling)

SL

UMS

Read

8

Absolute position actual

value (without modulo

compensation)

SL

UMS

Read

9

Part actual value 1st

measuring system

SL

0.01 % of max. load speed

3)

Read

10

Part actual value 2nd

measuring system

SL

0.01 % of max. load speed

3)

Read

AXIS

100

Contour deviation

SL

UMS

Read

101

Abs. compensation value

SL

UMS

Read

SPINDLE

200

Current speed setpoint

(before ramp generator)

SL

(0.1) RPM

Read

201

Speed setpoint (ramp

generator output)

SL

(0.1) RPM

Read

202

Speed actual value

SL

(0.1) RPM

Read

Explanation of digital I/O in NCK:

Function

identifier

Explanation

Max. permissible

number

Parameter 1

Parameter 2

Parameter 3

Parameter 4

01

Digital I/O in

NCK

32

Data group

21H

Data type

Signal

number

Axis/spindle

number

The digital I/O peripherals (e.g. 6 digital inputs of Central Service Board or maximum 2 mixed

I/O modules with 2 input and output bytes each) can also be used to a limited extent in the

NCK area.

The status of these inputs/outputs can be read from the PLC by means of the high-speed data

channels. However, the outputs cannot be written from the PLC!

_______

1)

Data format

SL.. Signed Long (32 bit)

2)

Unit UMS ... Units Machine system

(0, 1) RPM ... Revolutions / minute, load-related

0.1 rpm when MD bit 520* bit 3 =1

1 rpm when MD bit 520* bit 3 = 0

3)

Load speed: 400000H corresponds to 0.01% of the max. load speed

12–292

© Siemens AG 1992 All Rights Reserved 6FC5197- AA50

SINUMERIK 840C (IA)