Siemens SINUMERIK 840C User Manual

Page 223

6 NC Machine Data (NC MD), NC Setting Data (NC SD)

03.95

6.4 Axis-specific MD 1 (axial data 1)

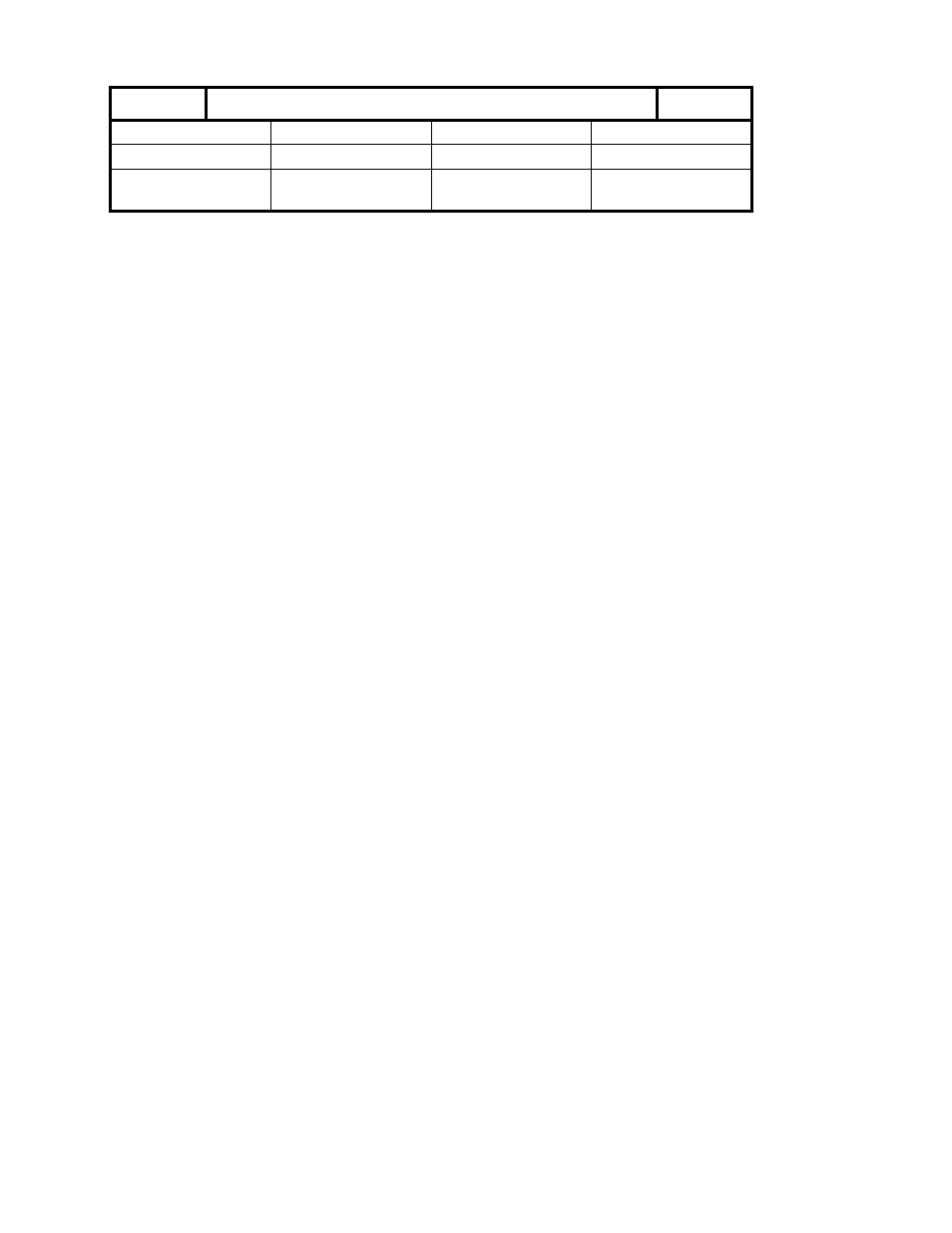

Coarse stop tolerance range

204*

Default value

Lower input limit

Upper input limit

Units

40

+0

16 000

units (MS)

40

+0

99 999 999

(as from SW 4.4)

units (MS)

Active on

NC Stop

The value defining the ”Coarse stop tolerance range ”can be higher than that defining the

”Fine stop tolerance range”. Consequently, a block change to the next machining block will be

initiated correspondingly sooner.

If this function is not required, it can be rendered ineffective by entering identical values in the

machine data locations for coarse exact stop and fine exact stop.

The coarse stop tolerance range is effective in the following cases:

•

G00

•

Block preceding G04

•

Block preceding setting data

•

Block ahead of which only auxiliary functions have been programmed

•

Single block without G60/G09

•

Jog

•

Incremental feed

•

End of program

Note:

The coarse stop tolerance range is not approached in continuous-path operation G64

(exception: G00 G64 coarse exact stop). There is no secondary error as a result of a large

number of consecutive positioning operations, as position control is not "deactivated" by the

stop tolerance range; instead, the second block is processed before the end position of the

first block is reached.

The current traversing path is now the remainder of block 1, block 2 and so on.

If the axis stops for an instant, e.g. because another axis is about to move or because there is

no axis movement in this program block, compensation is such that the following error is 0 and

the axis is precisely positioned. Also refer to NC MD 208* and 272*.

Note:

As from SW 4, for 8 parameter sets

6–38

©

Siemens AG 1992 All Rights Reserved 6FC5197- AA50

SINUMERIK 840C (IA)