Siemens SINUMERIK 840C User Manual

Page 258

12.93

6 NC Machine Data (NC MD), NC Setting Data (NC SD)

6.5 Spindle-specific MD (spindle data)

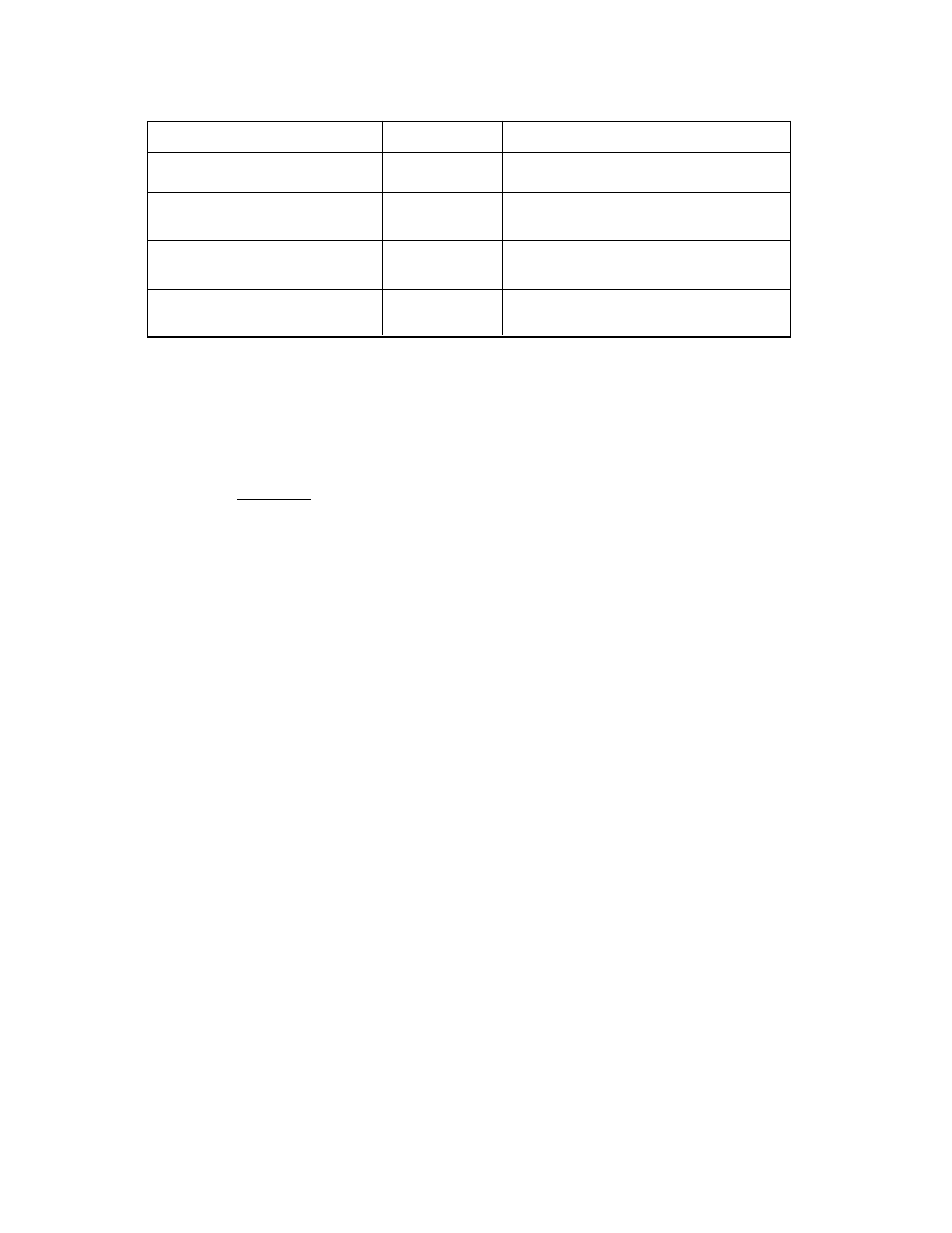

The parameters for defining MD 455* and 456* can be taken from the table below.

Parameters for defining MD 455* and 456*

Parameter

Symbol

Meaning

Position control resolution

b

Reference unit for traversing path

Pulses per resolution

p

Number of encoder pulses per

resolution

Pulse multiplication

f

Pulse multiplication for HMS

measuring circuit module; MD 458*

Measuring gear

r1

/r2

Gear transmission ratio between

spindle and encoder

MD 455* = 4

•

p

•

f

•

r2

Number of measuring system pulses per encoder revolution

including hardware multiplication; multiplied by r2

MD 456* =

360

•

r1

b

Number of internally computed increments per encoder revolution;

multiplied by r1

If the values thus calculated are greater than the input limits, common factors must be

reduced.

Recommendation: Always reduce when possible, at least for values 100 000

Notes

•

The position control resolution has been set to 0.5 x 10

-3

degrees for the spindle.

•

If the spindle is allocated to a C axis (MD 461*), the C axis resolution is used for the

calculations (MD 1800*, 364*, 368*).

•

The default values apply to the use of an SPC servo loop module and an encoder with

1024 pulses per revolution (see Example).

Examples

•

Encoder mounted directly on the spindle; square pulse encoder and SPC servo loop

module

b

=

0.5

•

10

-3

degrees

p

=

1024

pulses per revolution

f

=

1

no pulse multiplication

r1 =

1

no measuring gear

r2 =

1

If the spindle performs one full revolution, the encoder generates 4 x 1024=4096 pulses.

If these factors are introduced into the formula:

MD 4550 =

4 096

MD 4560 =

720 000

Reduction by the common factor 128 yields:

MD 4550 =

32

MD 4560 =

5625

©

Siemens AG 1992 All Rights Reserved 6FC5197- AA50

6–73

SINUMERIK 840C (IA)