1 mds for collision monitoring – Siemens SINUMERIK 840C User Manual

Page 390

07.97

6 NC Machine Data (NC MD), NC Setting Data (NC SD)

6.9.1 MDs for collision monitoring

6.9.1

MDs for collision monitoring

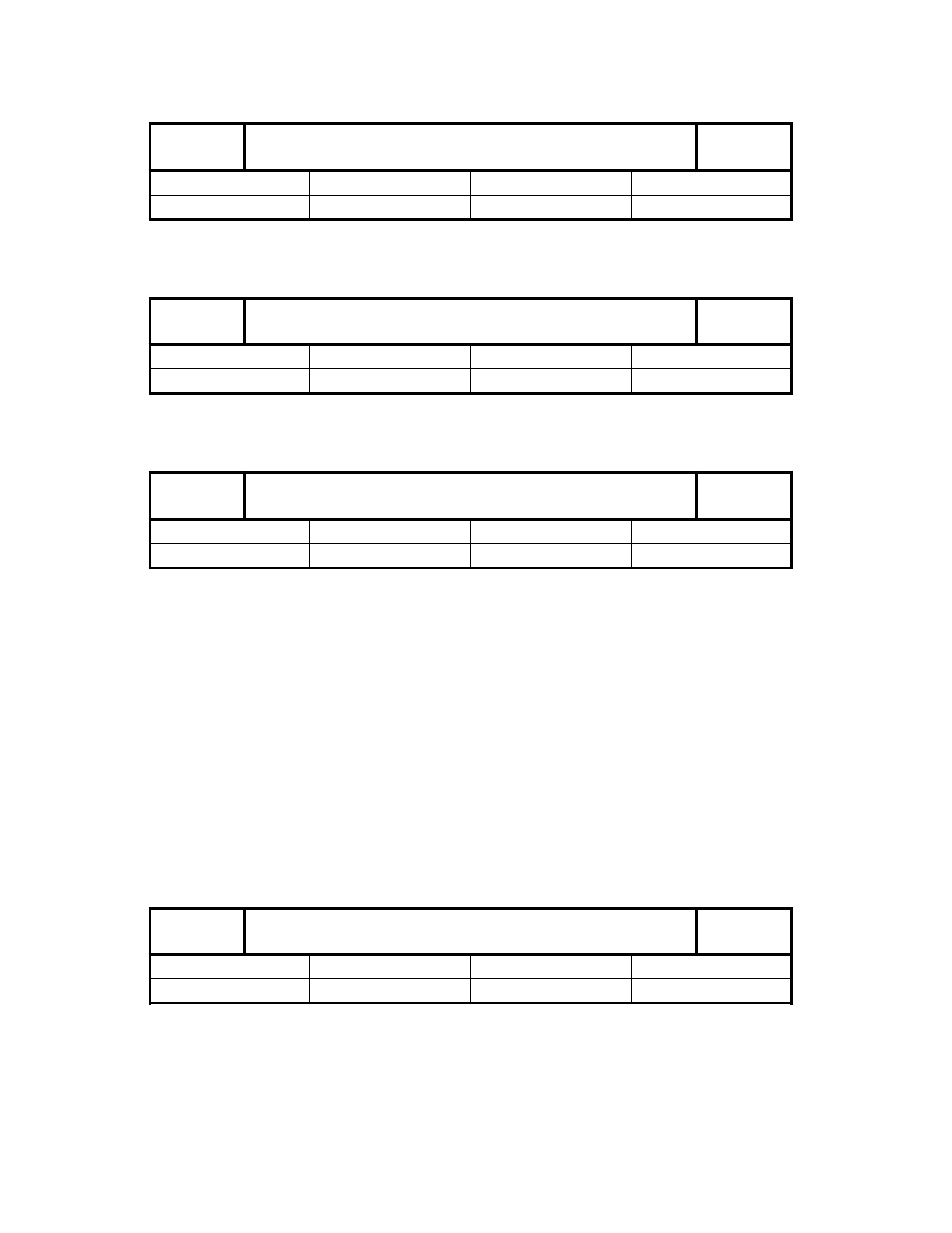

Motion axis X coordinate (as from SW 6)

3800*

Default value

Lower input limit

Upper input limit

Units

0

0

30

Axis no.

POWER ON

The motion axes are assigned to the protection zone in the protection-zone-specific machine

data.

Motion axis Y coordinate (as from SW 6)

3804*

Default value

Lower input limit

Upper input limit

Units

0

0

30

Axis no.

POWER ON

The motion axes are assigned to the protection zone in the protection-zone-specific machine

data.

Motion axis Z coordinate (as from SW 6)

3808*

Default value

Lower input limit

Upper input limit

Units

0

0

30

Axis no.

POWER ON

The motion axes are assigned to the protection zone in the protection-zone-specific machine

data:

*=Protection zone number

1st protection zone=0

2nd protection zone=1

to

32nd protection zone=31

The value entered is the global axis number. ZERO means no axis.

The axes must exist and belong to the same mode group. If an error occurs, alarm 111 ”Error

in collision monitoring data” is output.

The coordinates of protection zone reference point P1 are specified relative to slide reference

point F (protection zone reference point vector FP1) in the protection-zone-specific machine

data:

Protection zone reference point vector FP1

X coordinate (as from SW 6)

3812*

Default value

Lower input limit

Upper input limit

Units

0

0

99 999 999

MS

POWER ON

©

Siemens AG 1992 All Rights Reserved 6FC5197- AA50

6–205

SINUMERIK 840C (IA)