Section 21 – in-circuit debug mode, Ds4830a user’s guide – Maxim Integrated DS4830A Optical Microcontroller User Manual

Page 165

DS4830A User’s Guide

165

SECTION 21 – IN-CIRCUIT DEBUG MODE

The DS4830A is equipped with embedded debug hardware and embedded ROM firmware developed for the

purpose of providing in-circuit debugging capability to the user application. The in-circuit debug mode uses the

JTAG-compatible Test Access Port (TAP) as its means of communication between the host and the DS4830A.

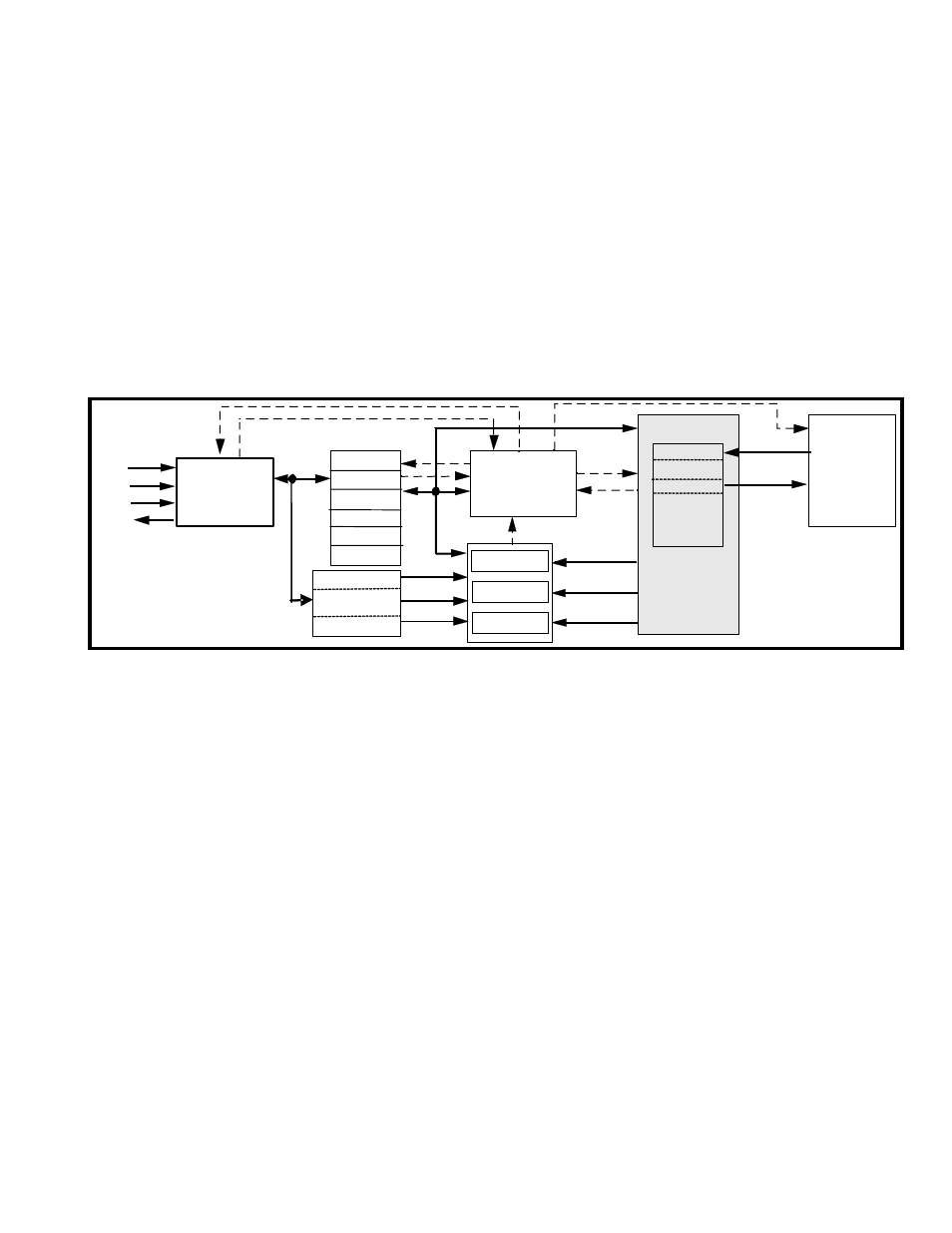

Figure 21-1 shows a block diagram of the in-circuit debugger. The in-circuit debug hardware and software features

include:

• a debug engine,

• a set of registers providing the ability to set breakpoints on register, code, or data,

• a set of debug service routines stored in a ROM.

Collectively, these hardware and software features allow two basic modes of in-circuit debugging:

• Background mode allows the host to configure and set up the in-circuit debugger while the CPU

continues to execute the normal program. Debug mode can be invoked from Background mode.

• Debug mode allows the debug engine to take control of the CPU, providing read write access to internal

registers and memory, and single step trace operation.

TMS

TDO

TDI

TCK

CPU

ROM

DEBUG

ENGINE

ICDB

ICDF

ICDC

BREAKPOINT

COMPARATOR

CODE ADDR

DATA ADDR

REG DATA

IP

IR

DATA

ADDR

ENABLE

BREAK

ICDA

ICDD

ICDTn

TAP

CONTROLLER

COMPARATOR

COMPARATOR

Figure 21-1: In-Circuit Debugger

The embedded hardware debug engine is implemented as a stand-alone hardware block in the DS4830A. The

debug engine can be enabled for monitoring internal activities and interacting with selected internal registers while

the CPU is executing user code. This capability allows the user to employ the embedded debug engine to debug the

actual system, in place of the in-circuit emulator that uses external hardware to duplicate operation of the

microcontroller outside of the real application environment.

To enable a communication link between the host and the microcontroller debug engine, the Debug instruction

(010b) must be loaded into the TAP instruction register using the IR-Scan sequence. Once the instruction is latched

in the instruction parallel buffer (IR2:0) and is recognized by the TAP controller in the Update-IR state, the 10-bit data

shift register is activated as the communication channel for DR-Scan sequences. The TAP instruction register retains

the Debug instruction until a new instruction is shifted via an IR-Scan or the TAP controller returns to the Test-Logic-

Reset state.

The host now can transmit and receive serial data through the 10-bit data shift register that exists between the TDI

input and TDO output during DR-Scan sequences. All background and debug mode communication (commands,

data input/output, and status) occurs via this serial channel. Each 10-bit exchange of data between the host and the

DS4830A internal hardware is composed of two status bits and a single byte of command or data. The 10-bit word is

always transmitted least significant bit first with the format shown in Figure 21-2. The details of the two status bits

are shown in Table 21-1.