Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C Frame) - Classic Control User Manual

Page 527

Troubleshooting

7-43

7000 “C” Frame

7000L-UM300I-EN-P – June 2013

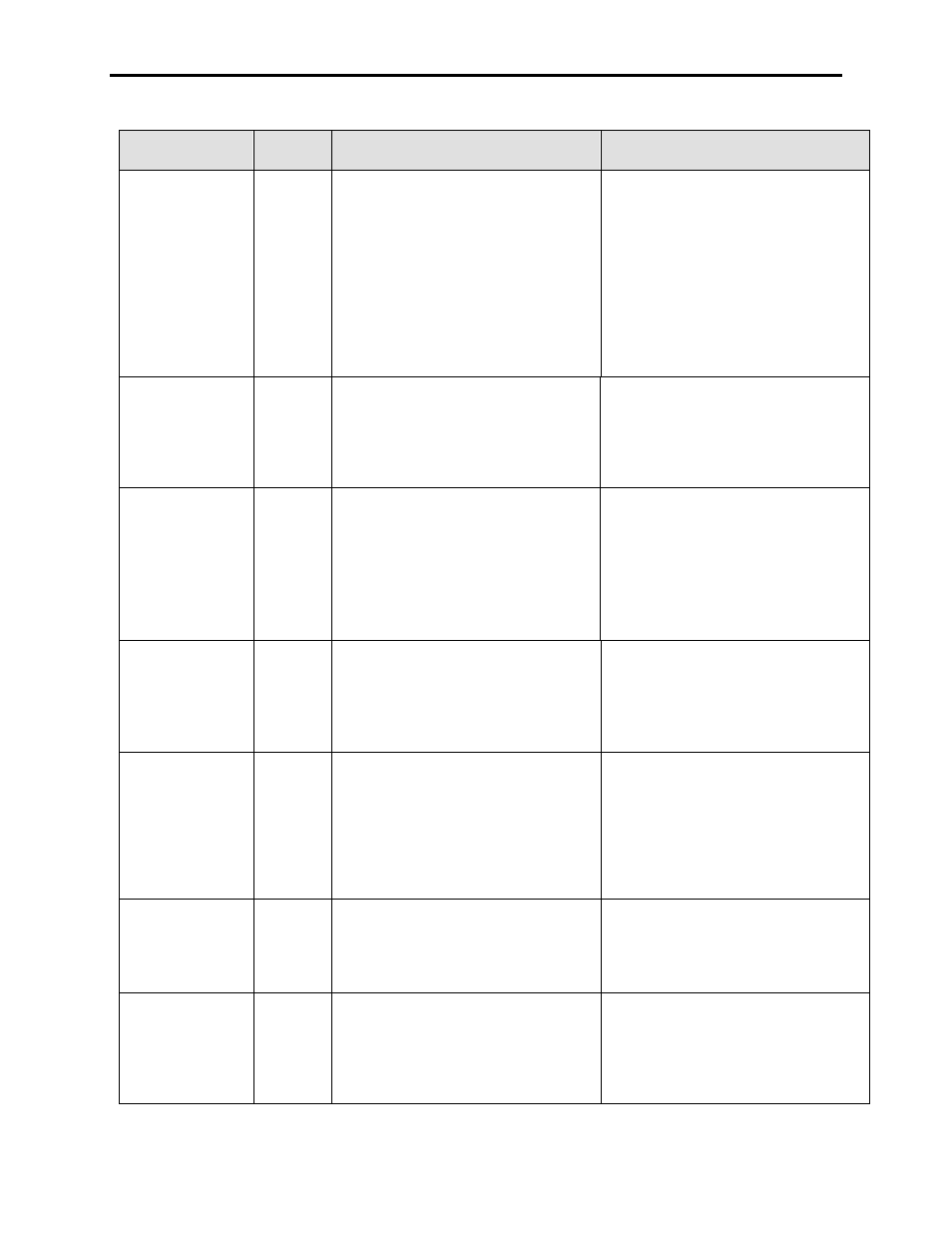

WARNING

MESSAGE

WARNING

CODE

DESCRIPTION

RECOMMENDED ACTIONS

Master UV

112

The measured value V Master Average

(P136) is less than Line Undervoltage Trip

(P167) with respect to 1/3 Rated Line

Voltage (P18) [for 18-pulse drives], and

Rated Line Voltage (P18) [for 6-pulse and

PWM drives] for the period set by Line

Undervoltage Delay (P168).

– Verify the VSB connections and tap

settings, and check resistance of VSB

board – Megger board to confirm integrity

– Check TSN fusing

– Check actual voltage values on the

Terminal for each bridge and the total

line voltage

– Check for possible source voltage

supply problems

– Use Multimeter and Oscilloscope to

check voltages on the drive test points

Motor Cap Range

23

The calculated per unit value of the Motor

Filter Capacitor (P128), based on the values

entered for Motor Capacitor kVAR (P20),

Motor Capacitor Volts (P21), and Motor

Capacitor Frequency (P28) is outside of the

normal range of 0.26-0.55 pu.

– Verify capacitor nameplate data and

compare with information entered in

drive

– Contact factory

Motor DC Link OV

192

DC Link Voltage on the motor side,

measured through the Voltage Sensing

Board, has exceeded Motor DC Overvoltage

Trip (P193), and instantaneously causes a

warning.

– Verify the motor is connected and the

Output Contactor is not open

– Verify there is no open SGCTs Complete

a Resistance and Firing check

– Check VSB circuit (grounds) through to

SCB-M

– Check Burden resistor values

– Check the trip parameter setting

Motor Load Loss

41

The drive has detected a loss of load

condition. This is activated as a warning

using the parameter Load Loss Detect

(P199), and the necessary setpoints are

Load Loss Level (P246), Load Loss Delay

(P231), and Load Loss Speed (P259).

– Verify the parameter settings

– Ensure that the load should not normally

be in an unloaded condition

Motor OL

17

A Motor Overload warning has been

detected, where the overload condition is

calculated using I Stator (P340) and Motor

Overload Warning (P351) as the point

where the overload warning occurs. P351 is

programmed as a percentage of the

difference between Motor Overload Min

(P350) and Motor Overload Trip (P179).

– Transient Loading - Check torque limit

and overload settings and Compare

loading to torque settings and trip

settings

Motor OV

193

The measured Motor AC Voltage has

exceeded Motor Overvoltage Trip (P181) for

the duration set in Motor Overvoltage Delay

(P182), but this has occurred with the drive

NOT gating (as in a Sync Transfer event)

Possible Causes:

Noise from contactor closure

Self-Excitation – Check for flying

start/induced motor rotation

Motor Protection

68

Standard External Fault/Warning Input

included to allow the end-user to install a

protective relay (IE Bulletin 825 Motor

Protection Relay) auxiliary contact that can

activate a drive fault or warning, depending

on configuration of Motor Prot Class (P443).

– See associated Fault Description