Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C Frame) - Classic Control User Manual

Page 502

7-18

Troubleshooting

7000L-UM300I-EN-P – June 2013

7000 “C” Frame

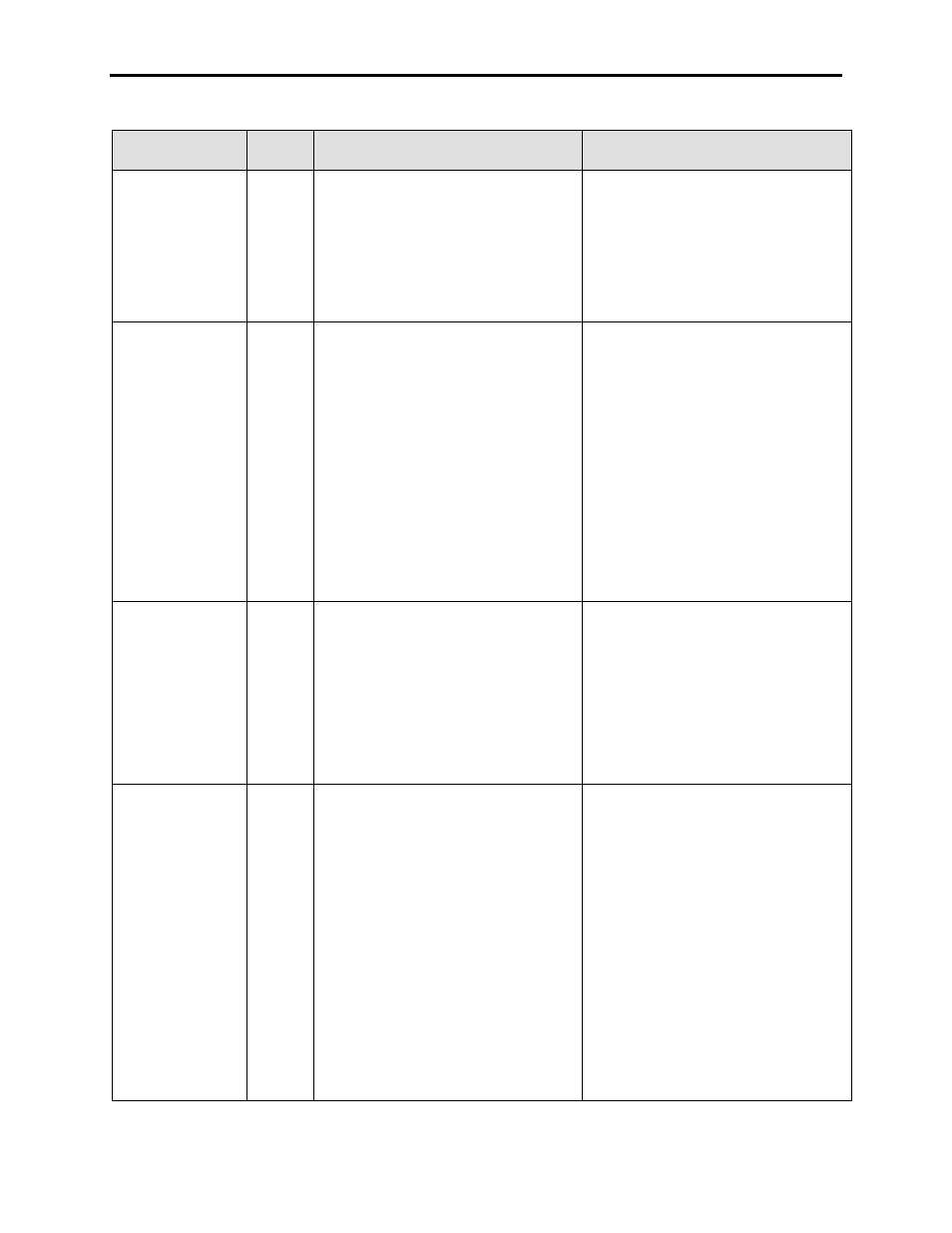

FAULT

MESSAGE

FAULT

CODE

DESCRIPTION

RECOMMENDED ACTIONS

Motor OV

22

The measured Motor AC Voltage has

exceeded Motor Overvoltage Trip (P181) for

the duration set in Motor Overvoltage Delay

(P182).

Possible Causes:

– Parameter setting incorrect (flux

command/trip values)

– VSB damage – Check VSB resistors,

grounds, and verify tap settings are

correct

– Self-Excitation – Check for flying

start/induced motor rotation

Motor Overspeed

66

The motor Speed Feedback (P289) has

exceeded Motor Overspeed Trip (P185) for

the duration set in Motor Overspeed Delay

(P186).

– Check for unbalance on the motor and

line feedback voltages

– Improper Settings – Check parameter

settings for Reference Command

Maximum and Ensure it is not too close

to Overspeed Trip increase

– Adjust Speed Regulator Bandwidth to

control overshoot, and ensure

acceleration rate near maximum speed is

not too great

– Check for load transients

– For Tachometers, ensure the ppr is set

properly and the feedback is valid

– Check tachometer pulse train with an

oscilloscope

Motor Protection

138

Standard External Fault/Warning Input

included to allow the end-user to install a

protective relay (IE Bulletin 825 Motor

Protection Relay) auxiliary contact that can

activate a drive fault or warning, depending

on configuration of Motor Prot Class (P443).

– Check device responsible for the

auxiliary contact to this input and

investigate the fault indicated by the

device‟s fault message

– Investigate internal and external causes

for this fault code

– Check the 120V signal through the

external device

– Check the XIO board inputs and

parameter status bits

Motor Stall

23

The drive has detected a motor stall

condition, with a delay set by Motor Stall

Delay (P191). The different methods of

Motor Stall detection depend on whether a

tachometer/encoder is installed or not.

Sensorless faults involve the motor not

building up enough flux feedback to be

detected by the drive, while tachometer

feedback methods look at the difference

between the tachometer/encoder feedback

and the speed command.

Possible Causes:

– Insufficient torque on starting– Increase

Torque Command 0 and 1 to avoid motor

stalls when starting if Speed Feedback

Mode is Sensorless

– Insufficient torque – Increase Torque

Limit Motoring to avoid motor stalls while

running

– Reverse Load Rotation – Ensure the

load is not rotating in the opposite

direction

– Increase motor stall delay

– Ensure Tachometer Feedback is

functional where applicable

– Ensure the motor is not spinning forward

at a speed greater than Reference

Command