3 fault messages, Fault messages, Troubleshooting and fault elimination – Lenze EDS4900U-REG User Manual

Page 249

Troubleshooting and fault elimination

8-4

48XX/49XXSHB0399

8.3

Fault messages

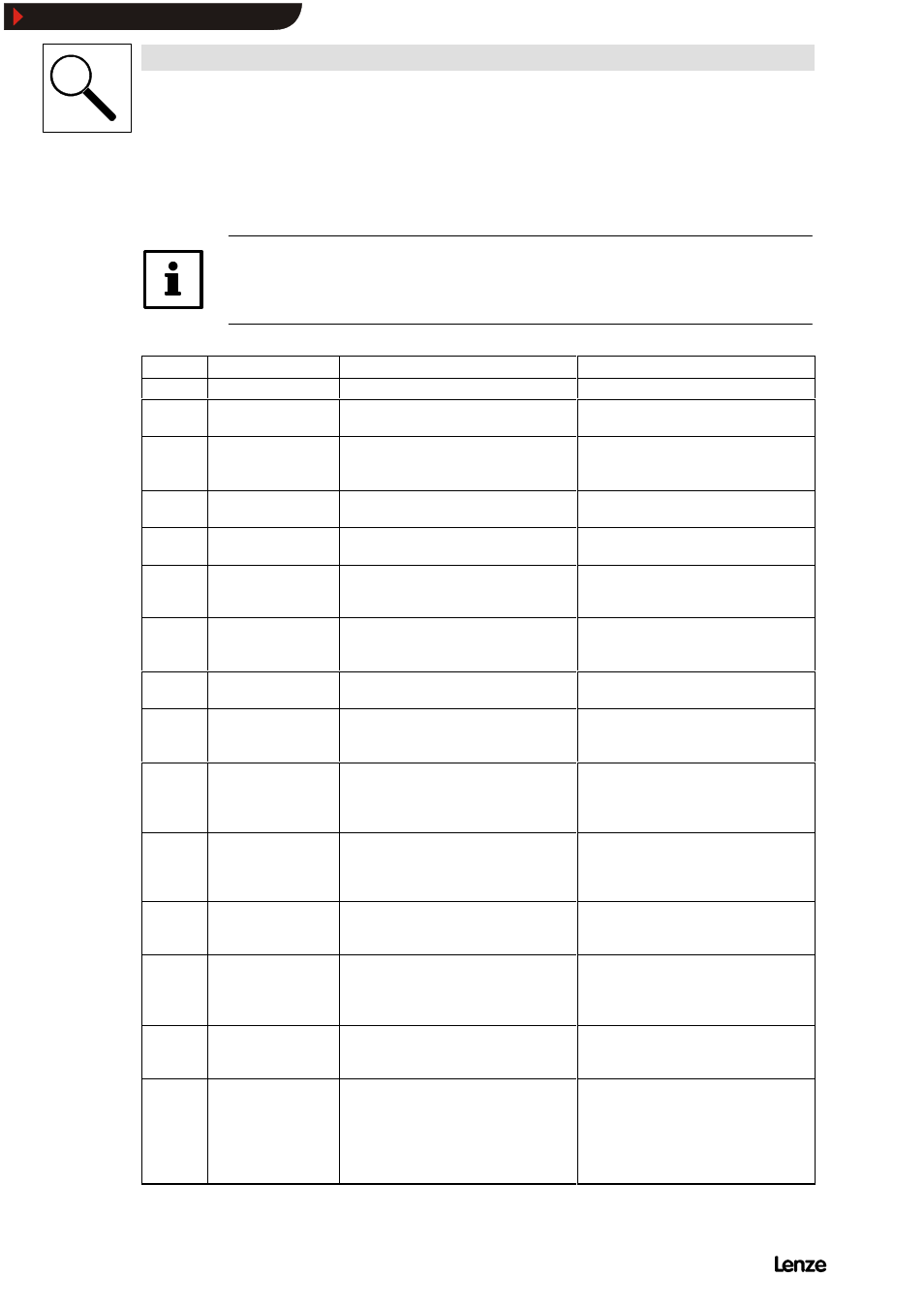

Note!

If the fault message is interrogated by a fieldbus, the fault message is represented

not by an abbreviation but a LECOM no. read from C167.

Display

Cause

Remedy

---

No fault

-

-

ACI

Armature circuit

interrupted

Defective fuse in the armature circuit or cable

interruption

Check armature fuse or remove cable

interruption

CCr

System fault

Strong interference on control cables

Ground or earth loops in the wiring

Screen control cables

Check PE wiring (see chapter 4.4”Installation

of a CE-typical drive system”)

CE0

Communication fault

(automation interface)

Interference during transmission of control

commands via the automation interface

Check wiring

CE9

Communication fault

(serial interface)

Faulty messages from the serial interface.

Check wiring

dEr

Motor blocked

High standstill torque or motor mechanically

blocked.

Remove motor blockage or increase blocking

time under C124 or blocking current under

C123.

EEr

External fault (TRIP-Set)

A digital input assigned to the TRIP-Set

function has been activated

Check external encoder.

Check polarity to activate TRIP set under

C118.

FCI

Field circuit interrupted

Defective field fuses F1 and F2 or

interrupted field circuit.

Replace field fuses when no voltage is applied

or remove cable interruption.

LF

Mains underfrequency

Mains frequency < 47Hz

Check mains frequency,

controller must only be driven within a

frequency range from 47 to 63 Hz.

LU

Undervoltage

Mains voltage < 340 V or 410 V

(Variant 500 V mains voltage)

Mains synchronisation has not detected any

voltage zero for more than 25 ms.

Increase electronics supply separately with a

connected transformer or

use a controller with a lower mains connection

voltage.

LU1

Phase failure

Failure of the mains voltage or mains

interruption

Check mains voltage and remove mains

interruption

Adapt mains synchronisation to mains

conditions under C237.

OC5

Controller overload

Frequent or excessive acceleration with

overcurrent

Permanent overload with I

A

> 1.05 I

Arated

Check drive dimensioning

OC6

Motor is thermally

overloaded

Motor is thermally overloaded by, for instance,

- impermissibly high continuous currents

- frequent and excessive

acceleration processes

Check drive dimensioning

OF

Mains overfrequency

Mains frequency > 63Hz

Check mains frequency

Controller must only be driven within a

frequency range from 47 to 63 Hz.

OH

Heat sink temperature is

higher than the value set

in the controller

Ambient temperature

T

amb

> 45

C or 35 C

Heat sink very dirty

Incorrect mounting position

Allow controller to cool and ensure better

ventilation

Check ambient temperature in the control

cabinet

Clean heat sink

Change mounting position

Show/Hide Bookmarks