Appendix – Lenze ECSCMxxx User Manual

Page 328

Appendix

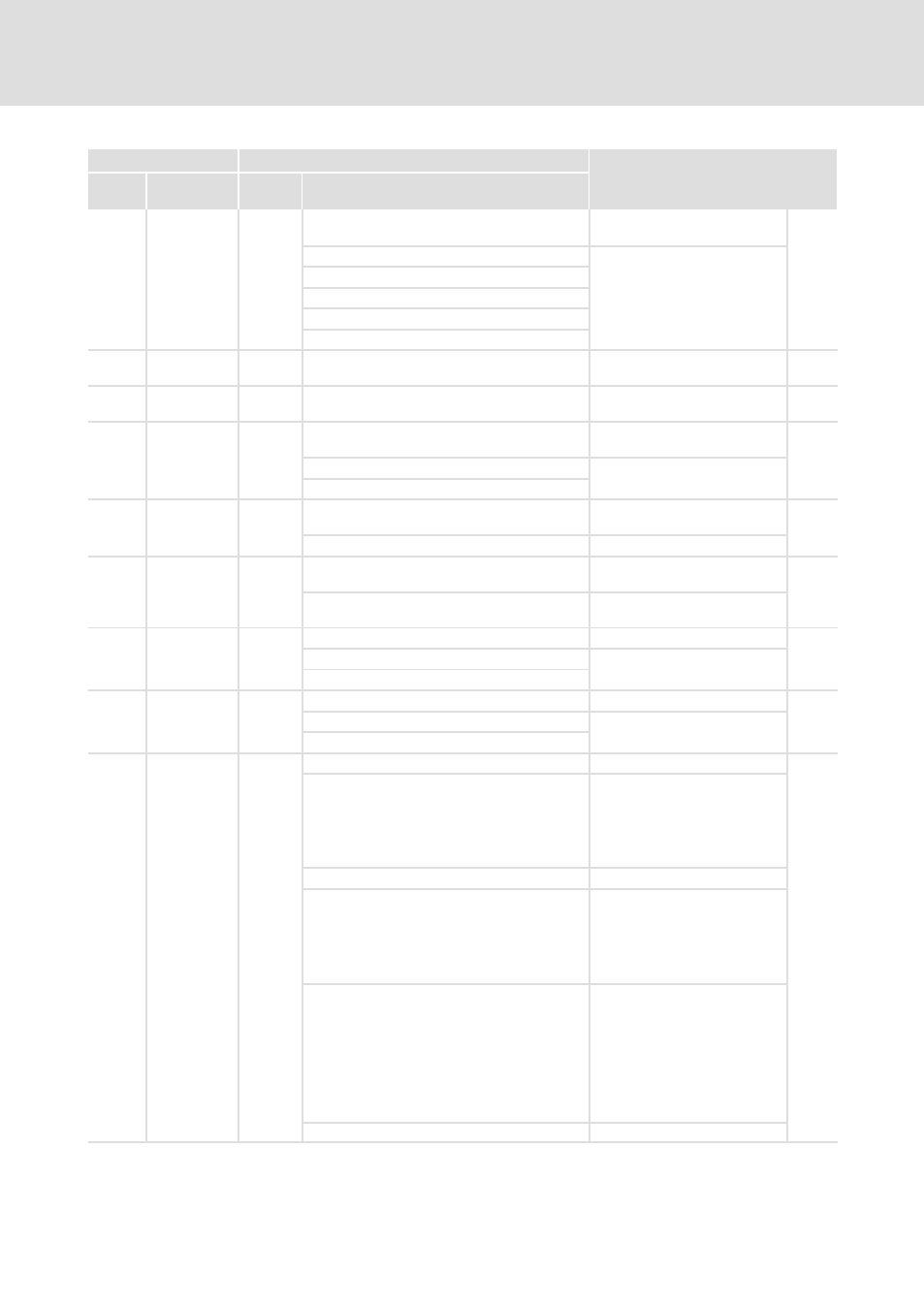

Code table

l

328

EDBCSXM064 EN 11.0

IMPORTANT

Possible settings

Code

Selection

Lenze/

{Appl.}

Designation

No.

C3201 FailReaction

0

Fault handling

Read only

0

TRIP

1

Message

2

Warning

3

FAIL−QSP

4

Not assigned

C3210 Failnumber

0

All fault indications

(TRIP, FAIL−QSP, warning, message)

Current fault number

Read only

^ 270

C3211 FailNumber

Old

0

All fault indications

(TRIP, FAIL−QSP, warning, message)

Previous fault number

Read only

^ 270

C3420 M_Pilot_

Contr

1

Torque feedforward control

0

Off

1

On

C3421 M_Operate_

TH

10

Torque operating threshold

0

{1 units}

16384

C3422 PilotCon

MGain

1.0

Gain of torque feedforward

control

1.00

{0.01

units}

100.00

C3430 NPilotControl

1

Speed feedforward control

0

Off

1

On

C4000 GlobalReset

0

Global reset of the PRG

0

Off

1

On

C4010 Ctrl_Interf

0

Control interface selection

^ 130

^ 167

^ 165

0

CAN1 (PDO1 with sync)

The control word is expected via

the PDO CAN1_IN. Control is

carried out via the CAN interface

X4 (MotionBus). Control and

status information is sent and

received via CAN1_IN (PDO1).

1

Without function

2

AIF X1 (PDO1 with sync)

Control via the automation

interface (AIF) X1 is only possible

in conjunction with the

EMF2192IB EtherCAT

communication module.

(From Motion V3.0)

3

C4040 (control via codes)

Control is carried out via codes.

The control word "Ctrl1" is set

via code C4040. The Global Drive

Control (GDC) diagnostics and

parameterisation software can

for instance be used to change

individual control bits in order to

simulate the higher−level control

for testing purposes.

4

Without function