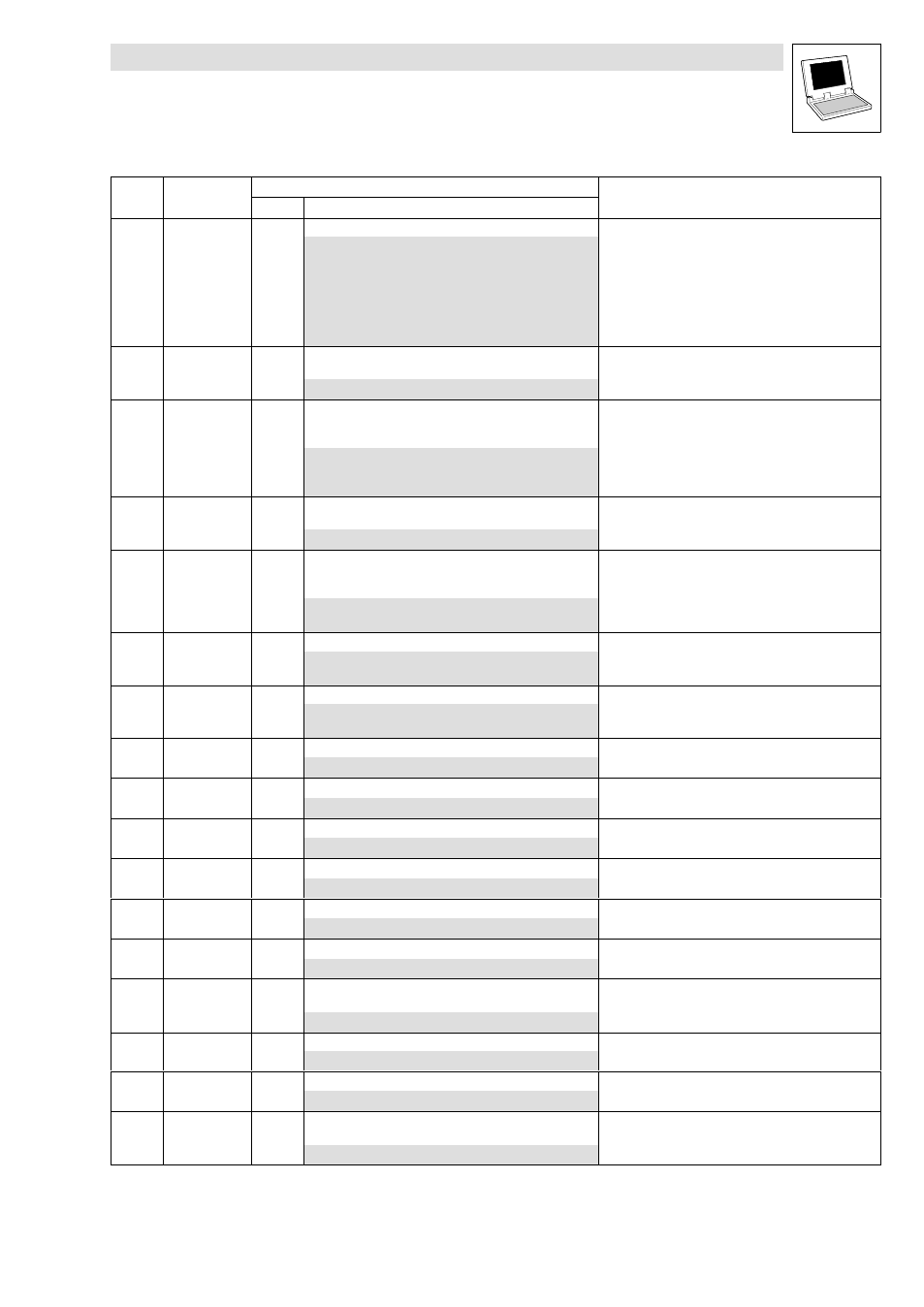

9300 servo plc, Appendix – Lenze DDS Target 9300 Servo PLC V8.x User Manual

Page 127

9300 Servo PLC

Appendix

3.6

Code table

3−121

L

9300 Servo PLC EN 5.1

Code

Information

Possible settings

LCD

Code

Information

Selection

Lenze

LCD

C0030 DFOUT const

3

Constant for the digital frequency output

0

256 increments per revolution

1

512 increments per revolution

2

1024 increments per revolution

3

2048 increments per revolution

4

4096 increments per revolution

5

8192 increments per revolution

6

16384 increments per revolution

C0032 FCODE Gearbox

1

Freely configurable code (absolute analog signals)

·

FCODE_nC32_a (gearbox factor numerator)

−32767

{1}

32767

C0034 Mst current

0

Analog input AIN1_nIn_a:

Selection: Master voltage/master current for setpoint

selection

0

−10 V ... + 10 V

1

+4 mA ... +20 mA

2

−20 mA ... +20 mA

C0037 Set−value rpm

0

Freely configurable code (absolute speed signals)

·

FCODE_nC37_a (setpoint selection in rpm)

−16000

{1 rpm}

16000

C0040 Ctrl enable

1

Controller inhibit (CINH)

·

Write to code: Enable/inhibit controller

·

Read code: Read controller status

0

Controller inhibited

1

Controller enabled

C0042 DIS: QSP

g

Quick stop status (QSP)

0

QSP not active

1

QSP active

C0043 Trip reset

0

TRIP reset

0

TRIP−RESET (Current TRIP reset)

1

Error occurred (TRIP is active)

C0050 MCTRL−NSET2

g

Speed setpoint at speed controller input (nNsetIn_a)

−100.00

{0.01 %}

100.00

C0051 MCTRL−NACT

g

Actual speed value

−30000

{1 rpm}

30000

C0052 MCTRL Umot

g

Motor voltage

0

{1 V}

800

C0053 UG−VOLTAGE

g

DC−bus voltage

0

{1 V}

900

C0054 Imot

g

Motor current

0.0

{0.1 A}

500.0

C0056 MCTRL−MSET2

g

Torque setpoint (nMSetIn_a)

−100.00

{0.01 %}

100.00

C0057 Max torque

g

Maximum possible torque of the drive configuration

·

Dependent on C0022, C0086

0.0

{0.1 Nm}

500.0

C0058 Rotor diff

0.0

Zero phase of the rotor for synchronous motors (C0095)

−180.0

{0.1

_}

179.9

C0059 Mot pole no.

g

Number of motor pole pairs

1

{1}

50

C0060 Rotor pos

g

Current rotor position

·

1 rev. = 2048 inc

0

{1}

2047