9300 servo plc, Appendix – Lenze DDS Target 9300 Servo PLC V8.x User Manual

Page 120

9300 Servo PLC

Appendix

3−114

L

9300 Servo PLC EN 5.1

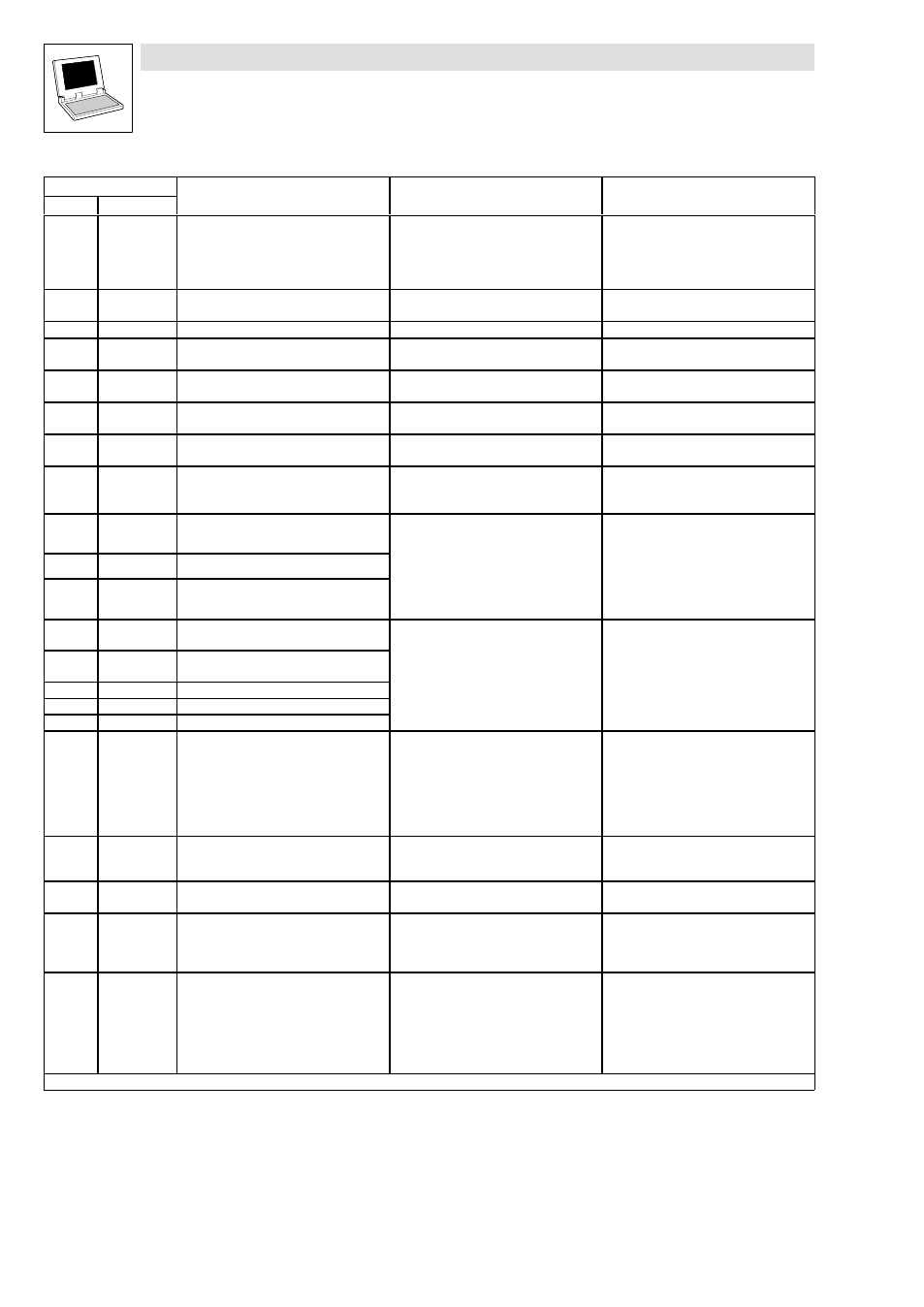

Fault message

Remedy

Cause

Description

No.

Remedy

Cause

Description

Display

x089

PL

Error during rotor position adjustment

·

Sd7 fault during rotor position

adjustment with absolute value encoder

after mains switching

·

Cancellation of rotor position adjustment

(e.g. by C0095 = 0 or switching off)

1. Activate rotor position adjustment with

C0095 = 1.

2. Carry out TRIP reset.

3. Repeat rotor position adjustment.

x091

EEr

External monitoring has been triggered via

DCTRL.

A digital signal assigned to the TRIP−SET

function has been activated.

·

Check external encoder.

·

Switch off the monitoring (C0581 = 3).

0105

H05

Internal fault (memory)

Contact Lenze.

0107

H07

Internal fault (power stage)

During initialisation of the controller, an

incorrect power stage was detected.

Contact Lenze.

x110

H10

Heatsink temperature sensor error

Sensor for detecting the heatsink

temperature indicates undefined values.

·

Contact Lenze.

·

Switch off the monitoring (C0588 = 3).

x111

H11

Temperature sensor error: Temperature

inside the controller

Sensor for detecting the internal

temperature indicates undefined values.

·

Contact Lenze.

·

Switch off the monitoring (C0588 = 3).

x190

nErr

Speed control error

(Speed out of tolerance margin (C0576))

·

Active load (e.g. for hoists) is too high.

·

Mechanical blockades on the load side

Check drive dimensioning.

x200

NMAX

Maximum system speed (C0596) has been

exceeded.

·

Active load (e.g. for hoists) is too high.

·

Drive is not speed−controlled, torque is

excessively limited.

·

Check drive dimensioning.

·

Increase torque limit, if necessary.

·

Switch off monitoring (C0607 = 3).

0201

overrun

Task1

Time−out in task 1 (ID 2)

Task processing takes longer than the

monitoring time set.

·

Adjust the length of the task runtime.

·

Adjust monitoring time.

·

Determine the cause of time−out by

checking the task runtime at the task

monitor.

·

Swap out time−critical program parts in

a slower task.

...

...

...

0208

overrun

Task8

Time−out in task 8 (ID 9)

0209

float

Sys−T

Float error in system task (ID 0)

Error in real calculation

(e. g. division by 0)

Check calculations (program code).

0210

float

Cycl.−T

Float error in cyclic task (PLC_PRG ID 1)

0211

float Task1

Float error in task 1 (ID 2)

...

...

...

0218

float Task8

Float error in task 8 (ID 9)

0219

overrun

Cyc.−T

Time−out in cyclic task (PLC_PRG ID 1)

Task processing takes longer than the

monitoring time set.

·

Adjust the length of the task runtime.

·

Adjust monitoring time.

·

Determine the cause of time−out by

checking the task runtime at the task

monitor.

·

Swap out time−critical program parts in

a slower task.

0220

noT−Fkt

Credit

Not enough technology units available.

A program with technology functions has

been tried to be loaded to a controller not

providing the corresponding units.

·

Use technology variant of the controller.

·

Contact Lenze, if necessary.

0230

No

Program

Missing PLC program

No PLC program loaded.

Load PLC program.

0231

Unallowed

Lib

PLC program calls invalid library function.

In the PLC program a library function has

been called which is not supported by the

controller (e.g. because the corresponding

hardware is missing).

·

Remove library function or ensure that

the corresponding hardware is available.

·

Contact Lenze, if necessary.

0232

NoCam

Data

Motion profiles (cam data) are not available. When calling functions of the function

library LenzeCamControl.lib it was

detected that there are no motion profiles

(CAM data) loaded in the memory of the

controller.

·

Ensure that the valid cam data has been

attached to the project via the DDS CAM

support.

·

Reload the PLC program into the

controller. (Possibly the command

Online

WReset (origin) has been

executed in DDS.)

x: 0 = TRIP, 1 = Message, 2 = Warning, 3 = FAIL−QSP