9300 servo plc, Appendix – Lenze DDS Target 9300 Servo PLC V8.x User Manual

Page 118

9300 Servo PLC

Appendix

3−112

L

9300 Servo PLC EN 5.1

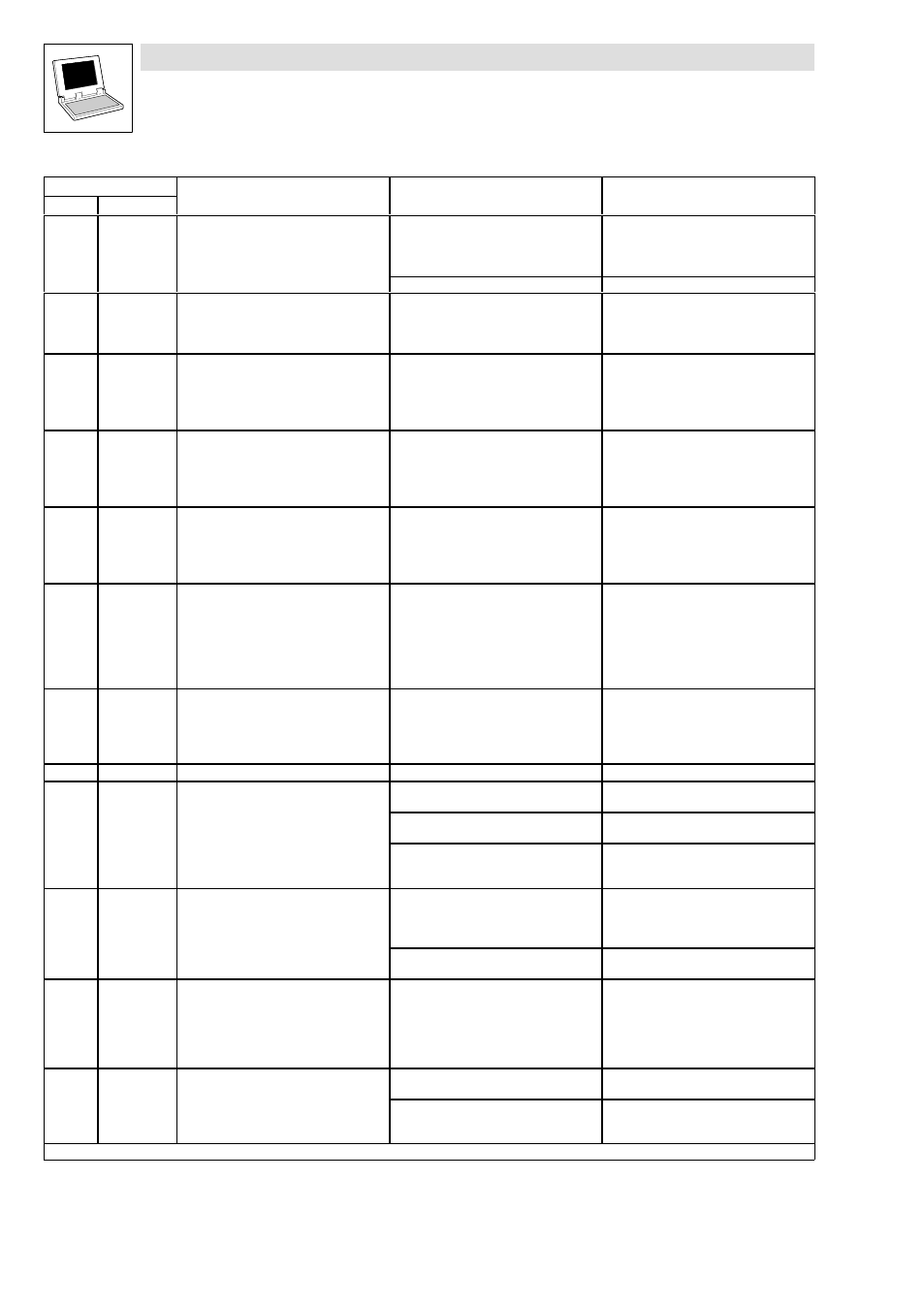

Fault message

Remedy

Cause

Description

No.

Remedy

Cause

Description

Display

x058

OH8

Motor temperature via inputs T1 and T2 is

too high.

Motor is thermally overloaded due to:

·

Impermissible continuous current

·

Frequent or too long acceleration

processes

·

Check drive dimensioning.

·

Switch off monitoring (C0585 = 3).

Terminals T1 and T2 are not connected

Connect PTC/temperature contact.

x061

CE0

Automation interface (AIF) communication

error

Faulty transfer of control commands via AIF.

·

Plug in the communication

module/keypad XT firmly, screw down, if

necessary.

·

Switch off monitoring (C0126 = 3).

x062

CE1

Communication error on the process data

input object CAN1_IN

CAN1_IN object receives faulty data or

communication is interrupted.

·

Check wiring at X4.

·

Check sender.

·

Increase monitoring time under

C0357/1, if necessary.

·

Switch off monitoring (C0591 = 3).

x063

CE2

Communication error on the process data

input object CAN2_IN

CAN2_IN object receives faulty data or

communication is interrupted.

·

Check wiring at X4.

·

Check sender.

·

Increase monitoring time under

C0357/2, if necessary.

·

Switch off monitoring (C0592 = 3).

x064

CE3

Communication error on the process data

input object CAN3_IN

CAN3_IN object receives faulty data or

communication is interrupted.

·

Check wiring at X4.

·

Check sender.

·

Increase monitoring time under

C0357/3, if necessary.

·

Switch off monitoring (C0593 = 3).

x065

CE4

BUS−OFF state of system bus (CAN)

The controller has received too many faulty

telegrams via the system bus (CAN) and has

disconnected from the bus.

·

Check wiring at X4: Is the bus correctly

terminated?

·

Check shield connection of the cables.

·

Check PE connection.

·

Check bus load, reduce the baud rate if

necessary. (Observe the cable length!)

·

Switch off the monitoring (C0595 = 3).

x066

CE5

Time−out of system bus (CAN)

(communication error of gateway function)

For remote parameterisation (C0370,

C0371) via system bus (CAN):

·

Slave does not respond.

·

Communication monitoring time has

been exceeded.

·

Check wiring of system bus (CAN).

·

Check CAN bus configuration.

0070

U15

Undervoltage of internal 15 V voltage supply

Check voltage supply.

0071

CCr

System failure

Strong interference injection on the control

cables

Screen control cables

Ground or earth loops in the wiring

·

Check wiring

·

Check PE connection

After troubleshooting: Deenergise the

device completely (disconnect 24 V

supply, discharge DC bus)!

0072

PR1

Checksum error in parameter set 1

CAUTION: The Lenze setting is loaded

automatically!

·

Fault when loading a parameter set.

·

Interruption while transmitting the

parameter set via keypad.

·

Set the required parameters and store

them under C0003 = 1.

·

As to PLC devices, check the use of

pointers.

The stored parameters are incompatible

with the loaded software version.

Store the parameter set under C0003 = 1

first to allow for a faults reset.

0074

PEr

Program error

Error in the program flow

Send the parameter set (on floppy

disk/CD−ROM) with a detailed description of

the problem to Lenze.

After troubleshooting: Deenergise the

device completely (disconnect 24 V

supply, discharge DC bus)!

0075

PR0

Error in parameter set.

The operating system software has been

updated.

Storage of the Lenze setting C0003 = 1.

After troubleshooting: Deenergise the

device completely (disconnect 24 V

supply, discharge DC bus)!

x: 0 = TRIP, 1 = Message, 2 = Warning, 3 = FAIL−QSP