Measurement conditions, Connection, Testing – Yokogawa PC-Based MX100 User Manual

Page 60: Wiring diagram for the -b12 and -b35 modules

2-31

SM MX100-01E

Testing

1

2

3

4

5

6

7

2.7.6

Measurement Accuracy Test

Measurement Conditions

• Measured CH is arbitrary (CH2 recommended). Also, please remember that the

measurement accuracy test is carried out at the two measurement intervals of 100 ms

and 200 ms, and the ranges and criteria differ for each.

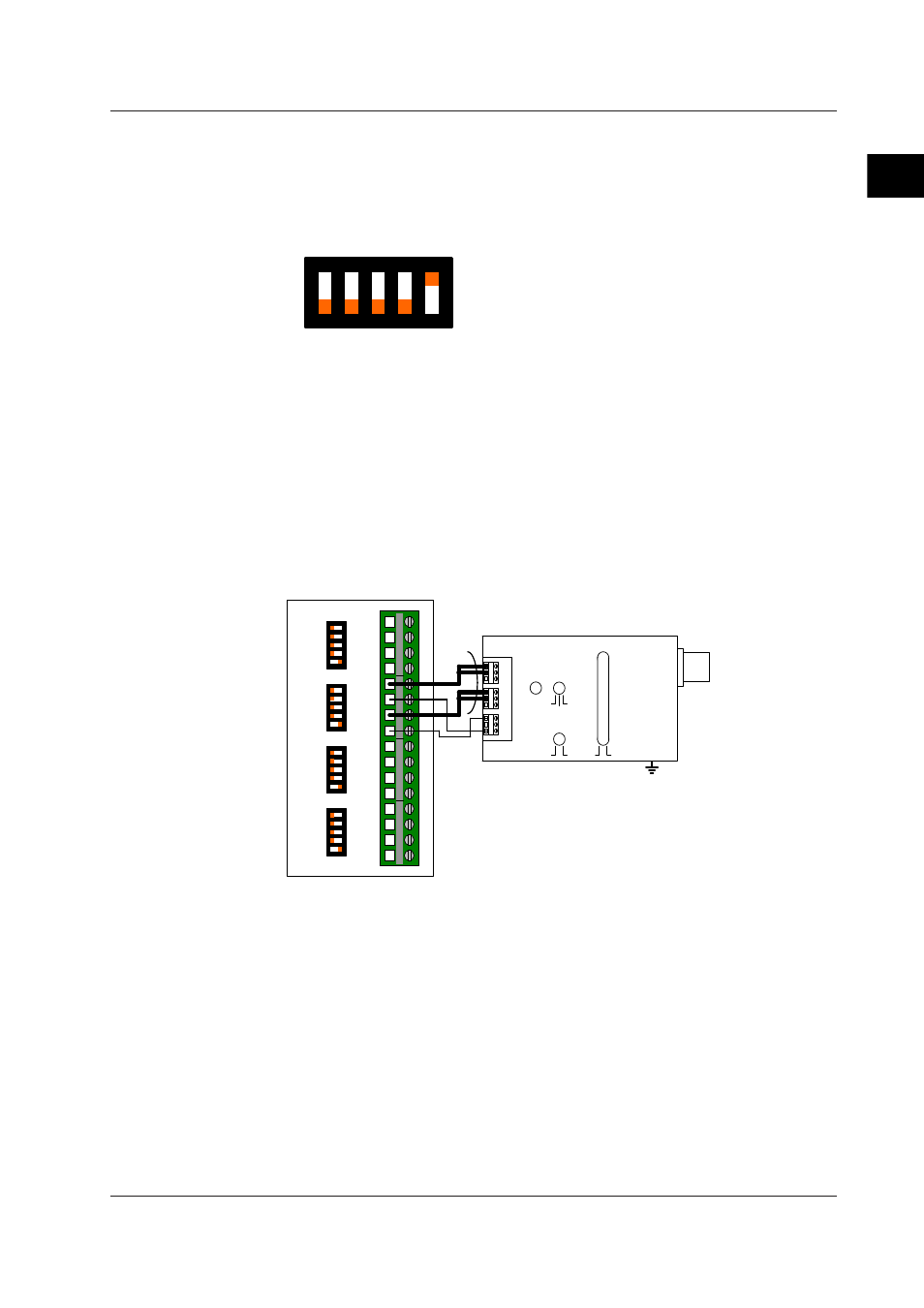

• Set the dip switches on the -B12 and -B35 modules for 4-gauge.

ON

1 2 3 4 5

SW1 to SW4: OFF

SW5: ON

• The duration of the measured data at the 100 ms interval should be five seconds or

more, and 10 seconds or more at 200 ms, and all measured data must be checked

against the test criteria.

• If ever a criterion is not met, the unit should be calibrated and retested.

• Before performing the measurement accuracy test, restore the initial balance values

(all measuring ranges) of the measurement channels from a PC via communication.

For instructions on restoring initial balance values through PC communication, see

the MX100 standard software user’s manual (IM MX180-01E) or the MW100 data

acquisition unit user’s manual (IM MW100-01E).

Connection

Wiring diagram for the -B12 and -B35 modules

RV1

OFF

SW8

SW7

0μSTR

P

P

PS

N

N

NS

H

-

L

-

+

OFF

ON OFF

ON

SW1

SW2

SW3

SW4

SW5

SW6

12000μSTR

30000μSTR

200000μSTR

2000μSTR

20000μSTR

10000μSTR

MX112 STRAIN CAL BOX

B8720XA

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ON

1

2

3

4

5

ON

1

2

3

4

5

ON

1

2

3

4

5

ON

1

2

3

4

5

A/+V

B/ L

C/-V

D/ H

CH1

A/+V

B/ L

C/-V

D/ H

CH2

A/+V

B/ L

C/-V

D/ H

CH3

A/+V

B/ L

C/-V

D/ H

CH4

P, N line

each 10 mΩ

or less

• Because the gain error will be equal to the wiring resistance of the P and N lines,

wiring must be performed so that each wiring resistance is kept to 10 mΩ or less.

• In the figure above, two P and N lines each are connected to the Cal Box in order to

reduce wiring resistance. You do not necessarily have to connect two lines each.

2.7 Tests of the 4-CH Strain Input Module