Liquid level probe - wiring detail, Ts-db1 splice kit (epoxy filled) – Franklin Fueling Systems Tank Sentinel (TS-1001, 2001, 504, 508 & 750) Installation User Manual

Page 52

SYSTEM WIRING

Page

7 - 9

7

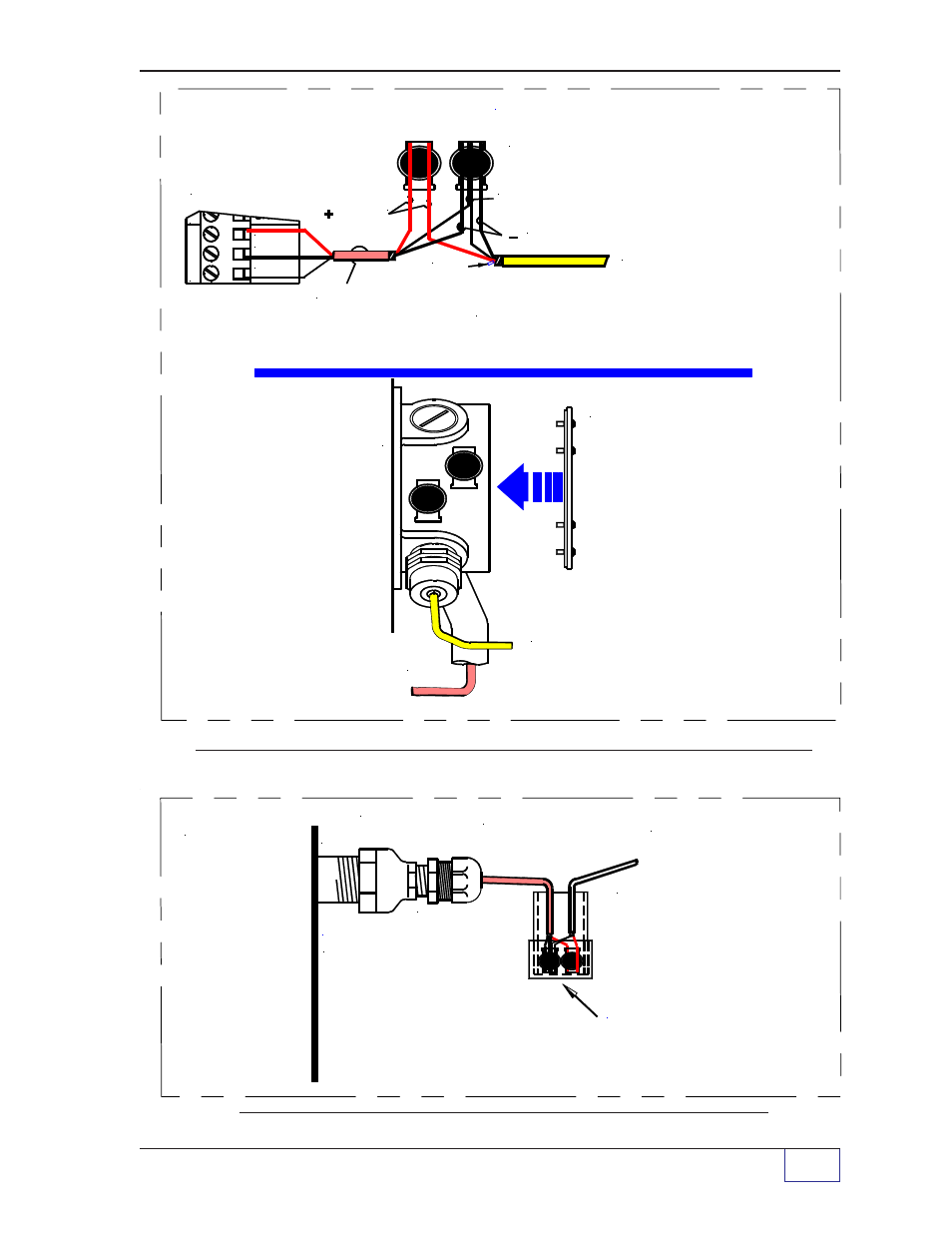

Figure 7-4a.

Console to Liquid Level Probe Wiring Detail (with J-Box)

Figure 7-4b.

Console to Liquid Level Probe Detail (without J-Box)

Liquid Level Probe - Wiring Detail

3 WIRE CABLE FROM CONSOLE

TO SPLICE:

INSERT UNSTRIPPED WIRES & USE SLIP-JOINT

PLIERS TO SEAT BLACK PIECE

A 3/4 to 1/2 NPT

bushing is required

for the compression

gland / cord grip

fitting when a

3/4 NPT Junction Box

is used

CABLE FROM CONSOLE

EYS FITTING (epoxy filled

seal fitting) is not shown

P

R

O

BE N

-(BLK)

SHLD

Probe N - Tank N

P

+(RED)

WHT

(RED)

or YEL

SEE WIRING ABOVE

WEATHERPROOF

JUNCTION BOX

COVER & GASKET

IS INSTALLED AFTER

PROBE IS TESTED

CABLE TO PROBE

3 or 4 WIRE CABLE

TO PROBE

(the white wire

may be cut off)

3 POSITION,

NO-STRIP ELECTRICAL CONNECTORS

(BLK)

SHLD

Also see Chapter 5 about Weatherproof Junction Boxes

CABLE

FROM

CONSOLE **

A 3/4 to 1/2

NPT reducing

coupling and a

compression

gland / cord-

grip fitting

is required

when a

3/4 NPT

Junction Box

is not used

COMPRESSION

FITTING

(SUPPLIED)

NOTE

** = COIL A

SERVICE-LOOP OF BOTH

CABLES TOGETHER AND

TIE TO THE RMC

SEAL ALL FITTING THREADS

WITH UL APPROVED &

CLASSIFIED "PIPE DOPE"

REDUCING

COUPLING

RMC

Some sensors, which are

suspended above a surface,

may still require the use

of a weatherproof junction

box

TS-DB1 SPLICE KIT

(EPOXY FILLED)

CABLE FROM

PROBE **

(OR SENSOR)