Franklin Fueling Systems Tank Sentinel (TS-1001, 2001, 504, 508 & 750) Installation User Manual

Page 41

LEVEL PROBE INSTALLATION

Page

6 - 7

6

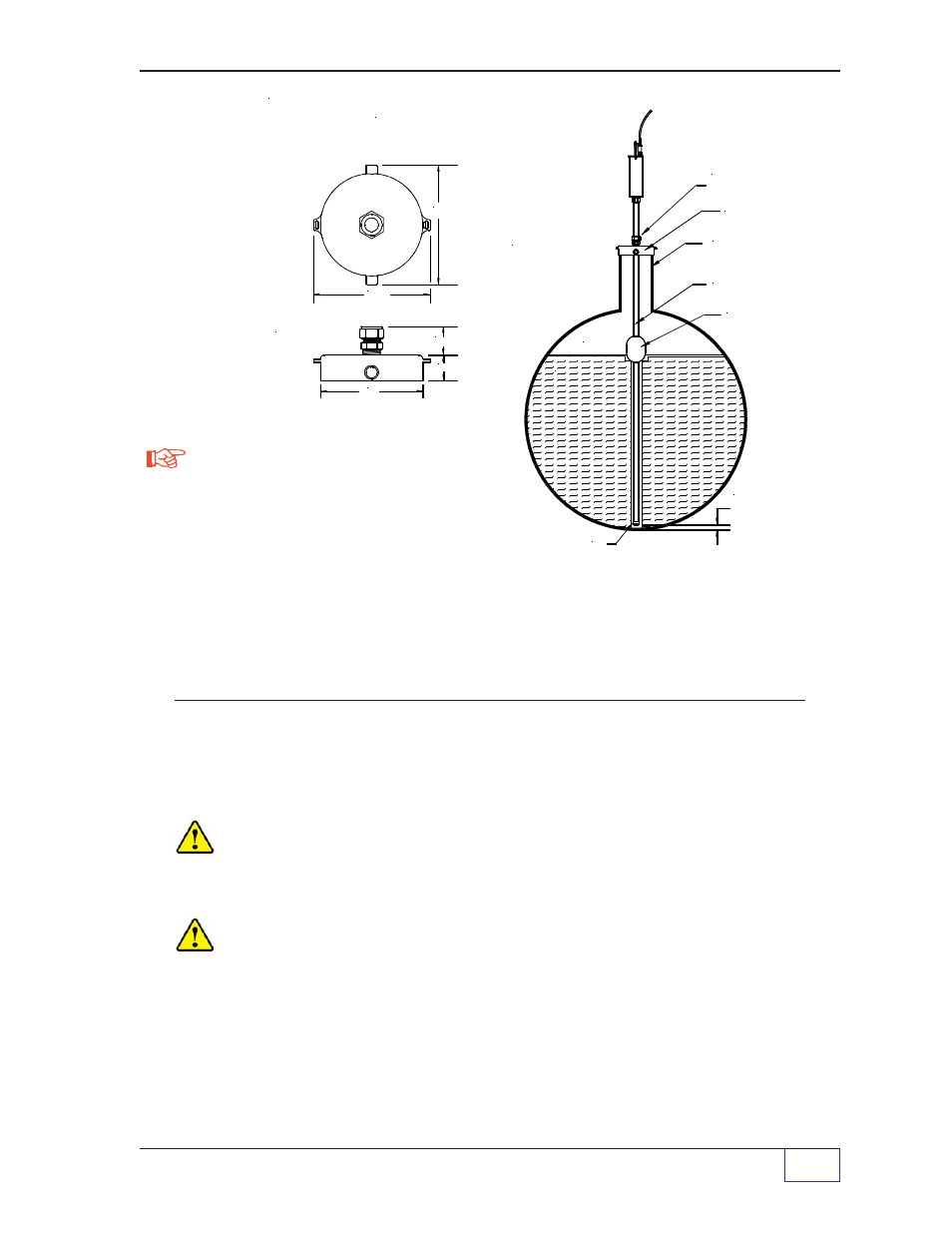

Figure 6-2

TSP-LL2C Chemical Probe Installation with a 2" (50.8 mm) TSP-SSP

Float

Floats – Standard Cautions and Notes

CAUTION Using the wrong floats on the TSP-LL2 level probe shaft will result

in erratic operation and incorrect level and volume data. Only use floats that are

designed for use with the TSP-LL2 liquid level probe.

CAUTION Avoid possible float damage, slide both floats down so they are at

the bottom of the probe shaft before you install the probe into the tank.

Other “2 inch” floats (model numbers TSP-IGF2, TSP-IDF2, and TSP-SSP) may be

used with the TSP-LL2 liquid level probe in special applications/products. Follow

the installation instructions provided with these floats.

NOTE: STEEL

TANKS MAY

REQUIRE AN

ISOLATION

BUSHING

PER LOCAL

CODES

SWAGELOCK

(MOUNTED)

5.0"

(127 mm)

1.25" (31.8 mm)

1.50" (38.1 mm)

FLOAT RETAINER

P R O D U C T

A I R

5.75"

(146 mm)

6.58" (167.1 mm)

TSP-K4AS

STAINLESS STEEL RISER CAP ADAPTER

FOR 4-INCH (101.6 mm) DIA. THREADED

RISER PIPES (8-NPT SS)

TSP-SSP PRODUCT FLOAT

(STAINLESS STEEL)

INSTALL PROBE

1/4" (6.4 mm) ABOVE

BOTTOM OF TANK

SWAGELOCK FITTING

(STAINLESS STEEL)

TSP-K4AS STAINLESS STEEL

RISER CAP ADAPTER

4 INCH DIA. SS RISER PIPE

(ANSI SCH. 40, MM 8-NPT)

DN115 BSP 4-11

TSP-LL2C PROBE SHAFT

(STAINLESS STEEL)

NOTE

1) Seal fitting threads with

pipe dope that is compatible

with the chemicals stored in the tank.

2.) With the probe resting on the bottom

of the tank, hand-tighten the top swagelock

fitting and mark the top of the swagelock fitting

with an indelible ink pen.

3.) Pull up on the probe 1/4" (6.4 mm) and tighten

the upper fitting so the probe doesn't move.