Use notes, Bifurcated fiber assembly specifications – Ocean Optics OOISensors User Manual

Page 113

6: Hardware Data Sheets and Instructions

Use Notes

• Gently remove the plastic cover from the SMA connector before use. Pulling the SMA connector

away from the fiber when removing the plastic cover will permanently damage the fiber.

• When fibers break, they stop transmitting light. Inspect fibers by eye to determine if light is being

transmitted.

• Do not coil the fiber too tightly, or bend it at a sharp angle. The maximum sustained bend radius of a

400 µm fiber is 10 cm. Bending the fiber can cause attenuation. To minimize this effect, add extra

strain relief to both ends of the fiber.

• Do not exceed the temperature specifications for the materials involved: 200°C for the fiber, 100°C

for PVC cabling, and 100°C for standard epoxy.

• Keep connectors and probe tips covered when the fibers are not being used.

• Clean ends of the fibers with lens paper and distilled water, alcohol, or acetone. Avoid scratching the

surface.

• Do not immerse fiber ends in caustic materials or other solutions that can damage quartz or

aluminum.

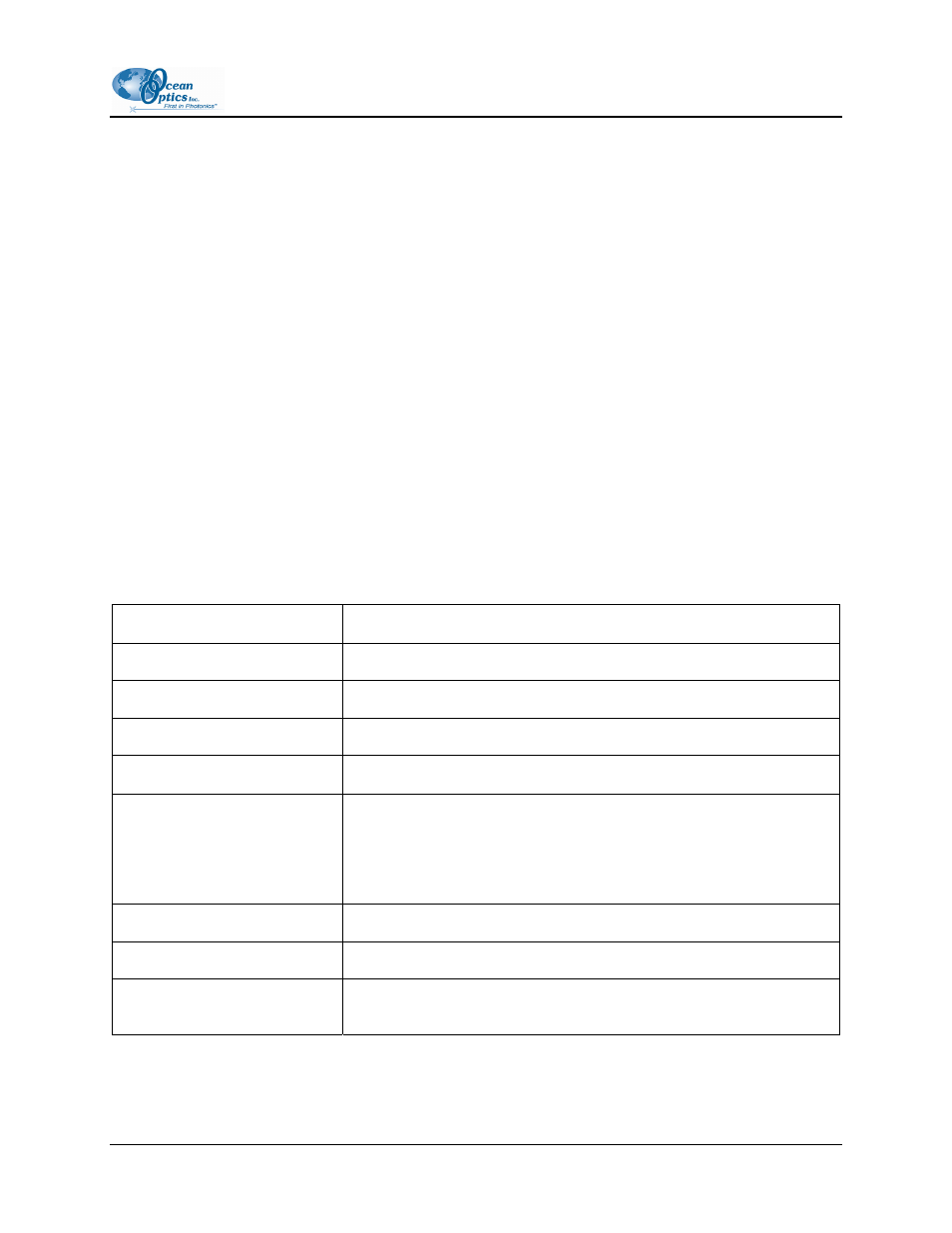

Bifurcated Fiber Assembly Specifications

Specification Value

Connector/termination SMA

905

Fiber core

Pure fused silica

Fiber cladding

Doped fused silica

Fiber buffer

Polyimide (temperature range -40

° C to +300° C)

Sheathing/cabling

PVC with Kevlar reinforcement (standard)

Silicone Monocoil (optional – autoclaveable)

Stainless steel BX flexible jacketing (optional)

Mode structure

Step-index multi-mode

Numerical aperture

0.22 ± .02

Recommended minimum bend

radius

Momentary = 200x the fiber radius; long term = 400x the fiber radius

FOXY-AL300-000-02-0207

103