12 connecting thermocouples – Siemens Simatic S7-400 User Manual

Page 269

Analog Modules

5-53

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

5.12

Connecting Thermocouples

Design of Thermocouples

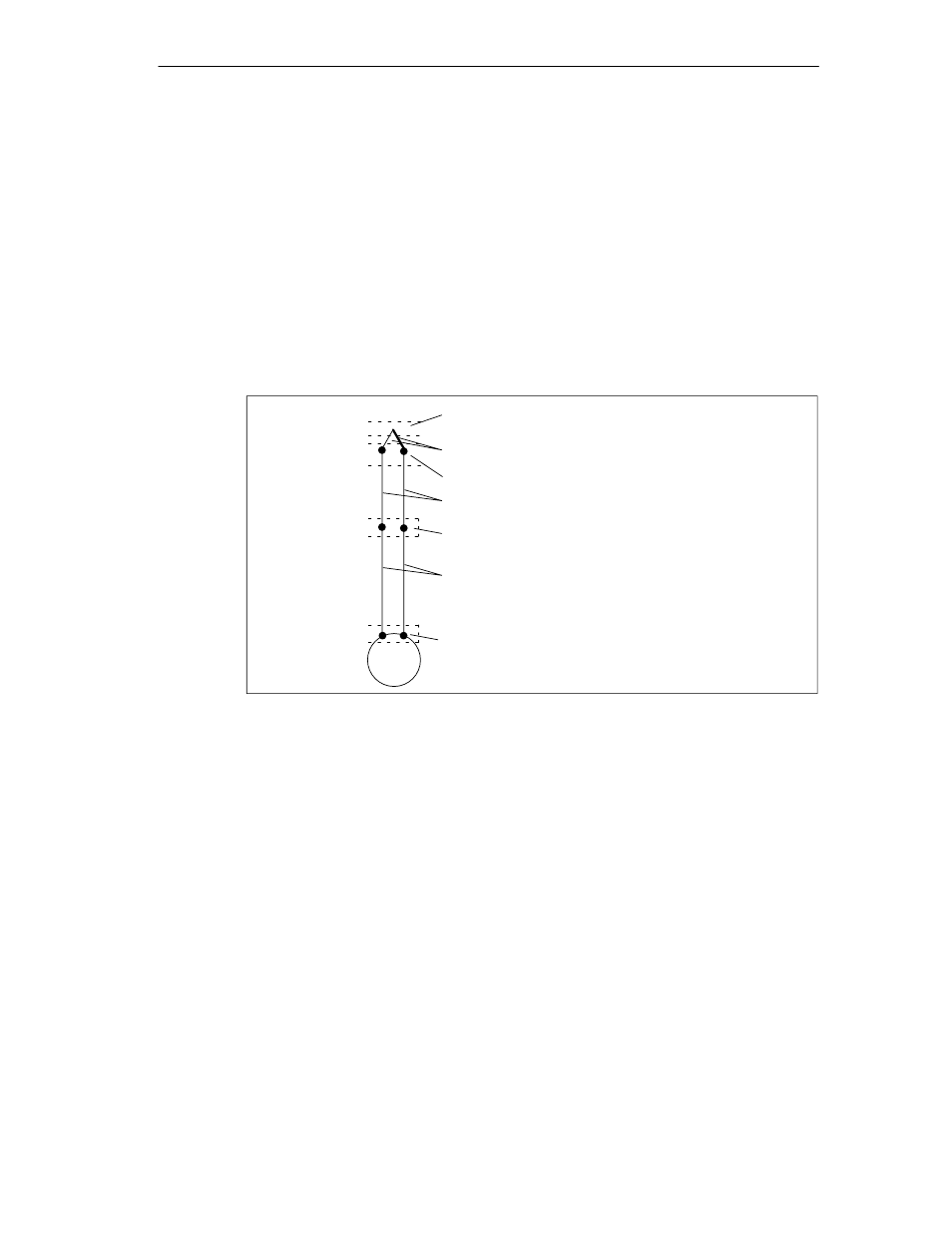

A thermocouple consists of a pair of sensors and the necessary installation and

connecting parts. The thermocouple consists of two wires of dissimilar metals or

metal alloys soldered or welded together at the ends.

There are different types of thermocouple, depending on the composition of the

material used – for example, K, J, N thermocouples. The measuring principle of all

thermocouples is the same, irrespective of their type.

(°(

C

Leads

Compensating leads

Reference

junction

Connecting point

Thermocouple with positive or

negative limbs

Measuring junction

Measurement input

Figure 5-17

Design of Thermocouples

Principle of Operation of Thermocouples

If the measuring point is subjected to a temperature different from that of the free

ends of the thermocouple (point of connection), a voltage, the thermo emf, occurs

at the free ends. The magnitude of the thermo-e.m.f. generated depends on the

difference between the temperature at the measuring junction and the temperature

at the free ends, as well as on the material combination used for the thermocouple.

Since a thermocouple always measures a temperature difference, the free ends

must be kept at a known temperature at a reference junction in order to determine

the temperature of the measuring junction.

The thermocouples can be extended from their point of connection to the reference

junction by means of compensating wires. These compensating wires consist of

the same material as the thermocouple wires. The supply leads are copper wire.

Note: Make sure these wires are connected with the correct polarity, otherwise

there will be considerable measuring errors.