Siemens Simatic S7-400 User Manual

Page 169

Digital Modules

4-47

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

4.12.1

Assigning Parameters to the SM 421; DI 16

24/60 VUC

Parameter Assignment

You will find a description of the general procedure for assigning parameters to

digital modules in Section 4.3.

Parameters of the SM 421; DI 16

24/60 VUC

The following table contains an overview of the parameters you can set and their

default settings for the SM 421; DI 16

24/60 VUC.

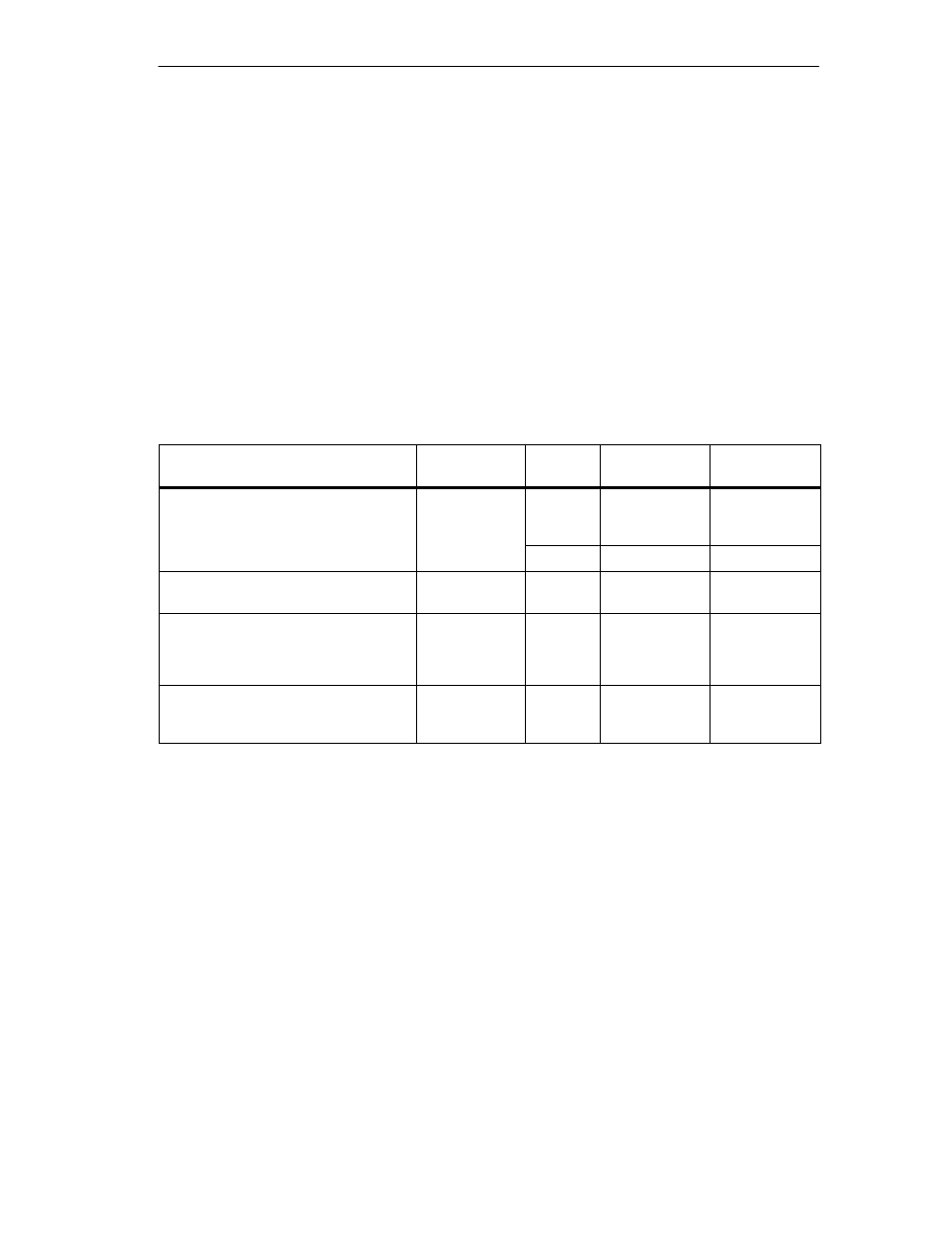

Table 4-16 Parameters of the SM 421; DI 16

24/60 VUC

Parameter

Value Range

Default

2)

Parameter

Type

Scope

Enable

•

Diagnostic interrupt

1)

•

Hardware interrupt

1)

Yes/no

Yes/no

No

No

Dynamic

Module

•

Destination CPU for interrupt

1 to 4

–

Static

Module

Diagnostics

•

Wire break

Yes/no

No

Static

Channel

Trigger for hardware interrupt

•

Rising (positive) edge

•

Falling (negative) edge

Yes/no

Yes/no

–

Dynamic

Channel

Input delay

3)

0.5 ms (DC)

3 ms (DC)

20 ms (DC/AC)

3 (DC)

Static

Channel group

1)

If you use the module in ER-1/ER-2, you must set this parameter to “No” because the interrupt lines are

not available in ER-1/ER-2.

2)

Only in the CC (central controller) is it possible to start up the digital modules with the default settings.

3)

If you assign 0.5 ms , then you should not parameterize a diagnosis because the internal processing time

for diagnostic functions can be > 0.5 ms.

Ensuring a Wire Break Check Is Carried Out

To ensure that a wire break check is carried out, you require an external sensor

circuit using a resistor of 18 to 56 k

W.

The resistor should be connected parallel to

the contact and should be arranged as closely as possible to the sensor.

This additional resistor is not required in the following cases:

•

If two-wire BEROs are used

•

If you don’t parameterize the “Wire Break” diagnosis