Labconco PURICARE Procedure Station Models 34812xx User Manual

Page 66

Page 66 of 197

Table 5-1

HEPA Filter Leak Test Specifications

Model

34308 34300 34408 34400 34508 34500 34608 34600

Air

Displacement

(CFM) 543 596 723 794 903 991 1083 1189

Laskin

Nozzles

needed 1 1 2 2 2 2 2 2

Calculated aerosol conc.

(ug/l)

1

25 23 38 34 30 27 25 23

Actual aerosol conc. (ug/l)

2

14 12 21 18 17 15 17 15

Nominal Speed Control

Setting

50-60 55-65 65-75 75-85 75-85 80-90 65-75 75-85

1. The calculated concentration was established by the formula:

Concentration (ug/l) = (# Laskin nozzles @ 20 PSIG x 13,500)/Volume of air displaced

2. Based on Mineral oil

1. Turn on the photometer and allow it to operate for a minimum of 5 minutes.

Leave the valve in the “CLEAR” setting.

2. Check the oil level of the generator – it must be within 1/8” of the level line

when the generator is sitting level.

3. Establish the 100% and 0% concentration levels for the photometer.

Removing the Exhaust HEPA Filter Cover

On Models Manufactured prior to April 2009 –

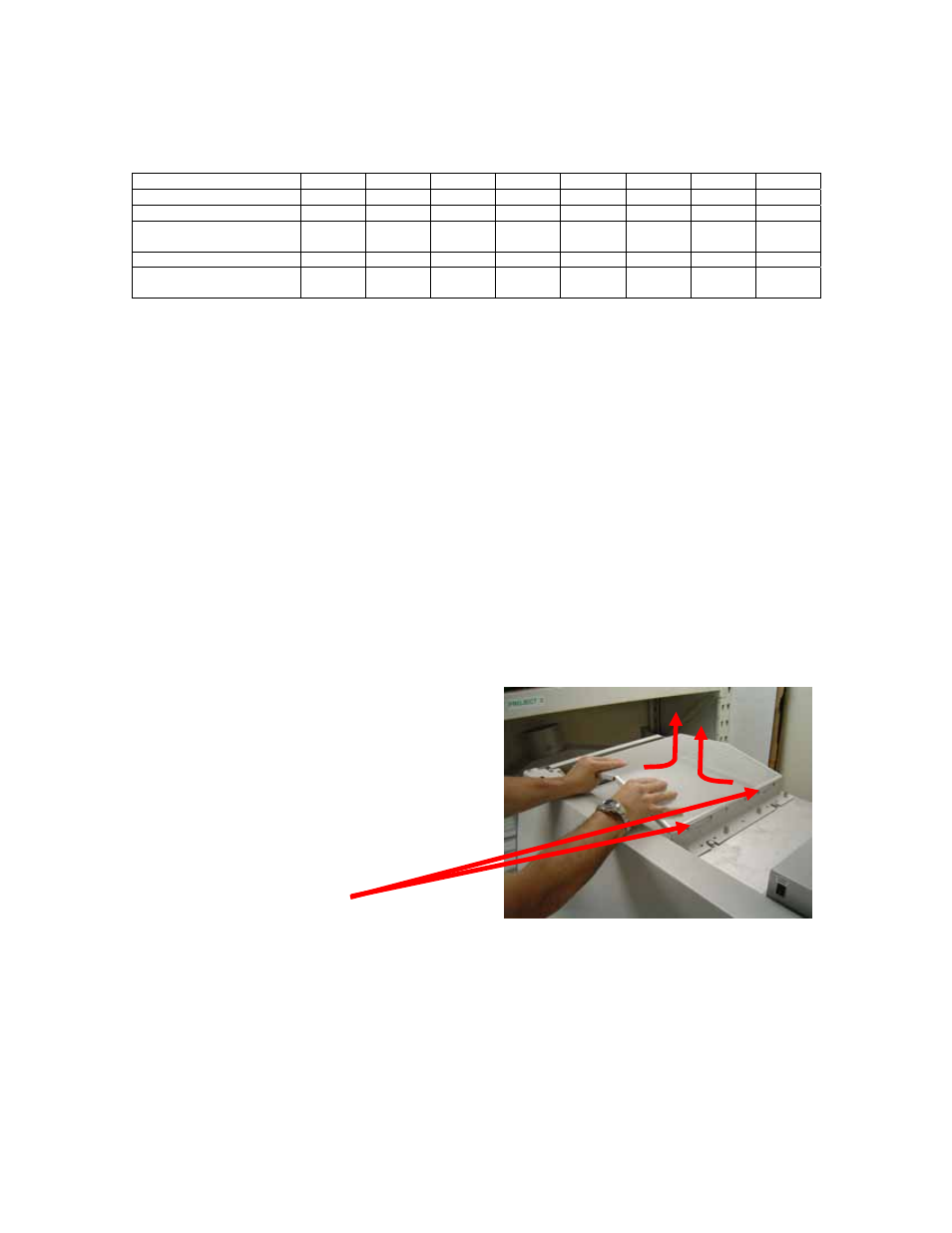

4. Remove the exhaust HEPA filter cover by lifting and compressing the cover until

its tabs are clear of the exhaust filter bracket, as shown in Figure 5-2.

Figure 5-2

Lift the center of the cover up while

compressing the cover.

Cover tabs in bracket slots

- PURICARE Procedure Station Models 34810xx PURICARE Procedure Station Models 34802xx PURICARE Procedure Station Models 34800xx Type B2 Biosafety Cabinets Models 34610xx Type B2 Biosafety Cabinets Models 34410xx Type A2 Biosafety Cabinets Models 34609 Type A2 Biosafety Cabinets Models 34509 Type A2 Biosafety Cabinets Models 34409 Type A2 Biosafety Cabinets Models 34309 Type A2 Biosafety Cabinets Models 34608xx Type A2 Biosafety Cabinets Models 34508xx Type A2 Biosafety Cabinets Models 34408xx Type A2 Biosafety Cabinets Models 34308xx Type A2 Biosafety Cabinets Models 34600xx Type A2 Biosafety Cabinets Models 34500xx Type A2 Biosafety Cabinets Models 34400xx Type A2 Biosafety Cabinets Models 34300xx