Specifications for stacked stages – Rockwell Automation CHPS-250 Linear Stage Installation User Manual

Page 90

90

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Appendix C Stacking Stages

Specifications for Stacked

Stages

Linear stage specifications are based on mounting the stage to a precision base

along the entire length of the stage, and MPAS stage specifications follow this

convention. In the case of stacked stages, the top axis is no longer supported along

its entire length, and this alters both the precision and the load carrying capability

of that stage. Furthermore, linear stage specifications are based on a specified test

payload with a low center of gravity that is centered on the carriage. Deviations

from the test payload condition can impact the performance of both the top and

bottom linear stages.

The following table provides information about the payload that the top stage, or

axis, can carry without derating the life of its bearings from those specified for the

same stage mounted as a single-axis stage on a precision base.

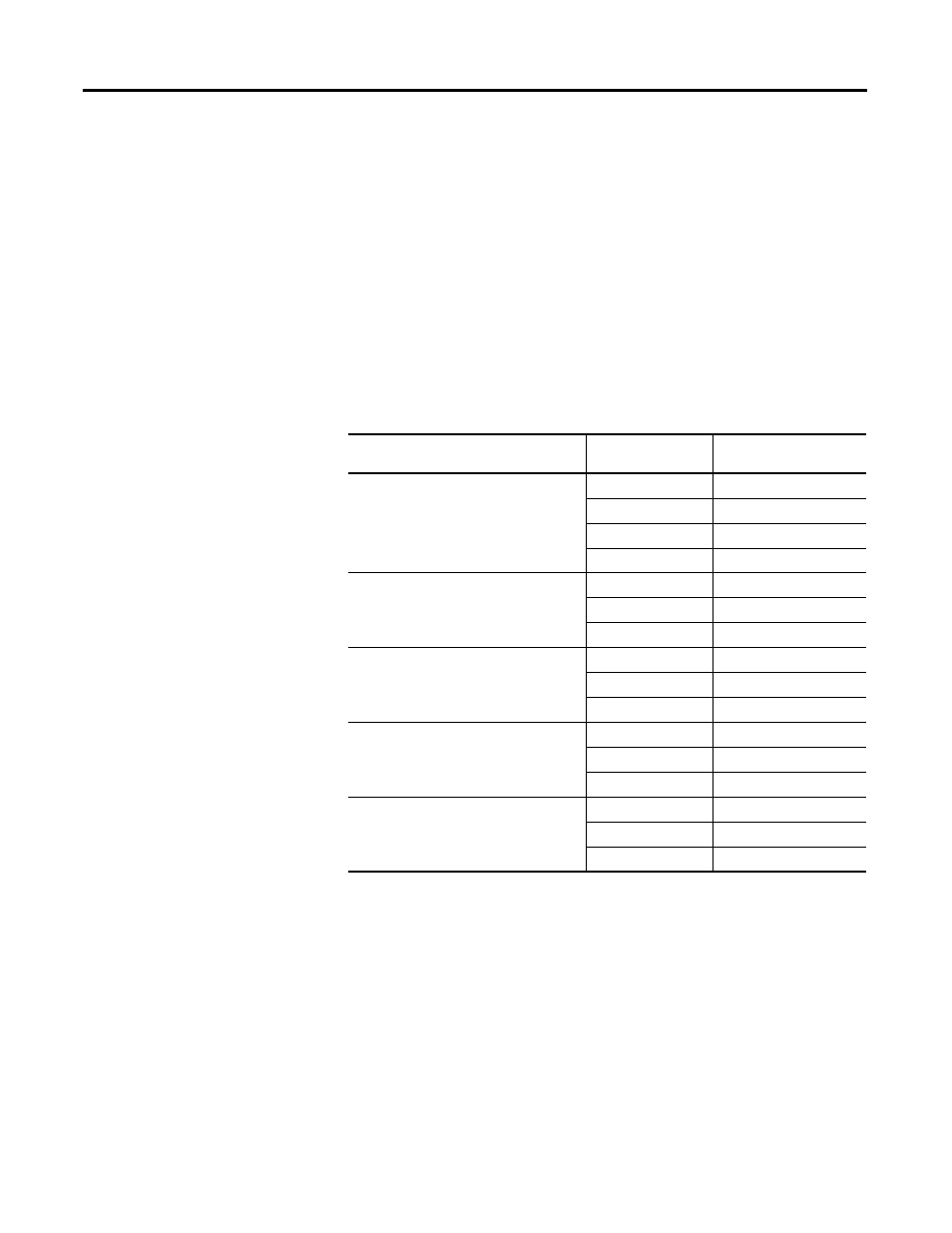

Table 13 - Centered Stack Combinations Not Requiring Derating

For other stacking arrangements, please contact Rockwell Automation

Application Engineering.

Catalog Numbers of

Centered Stack Linear Stages

Y-axis Travel

Mass of Payload

(1)

(1) Payload is based solely on bearing and structure limitations.

MPAS-x6xxxx on MPAS-x6xxxx

Ball Screw

or Direct Drive

300 10.0 kg

(22

lb)

420 8.0 kg

(17.6

lb)

540 5.0 kg

(11

lb)

660 4.0 kg

(8.8

lb)

MPAS-x8xxxx on MPAS-x8xxxx

Direct Drive

320 14.0 kg

(30.8

lb)

560 6.5 kg

(14.3

lb)

800 3.0 kg

(6.6

lb)

MPAS-x8xxxx on MPAS-x9xxxx

Direct Drive

320 14.0 kg

(30.8

lb)

560 6.5 kg

(14.3

lb)

800 3.0 kg

(6.6

lb)

MPAS-x8xxxx on MPAS-x8xxxx

Ball Screw

300 14.0 kg

(30.8

lb)

540 6.5 kg

(14.3

lb)

780 3.0 kg

(6.6

lb)

MPAS-x8xxxx on MPAS-x9xxxx

Ball Screw

300 14.0 kg

(30.8

lb)

540 6.5 kg

(14.3

lb)

780 3.0 kg

(6.6

lb)