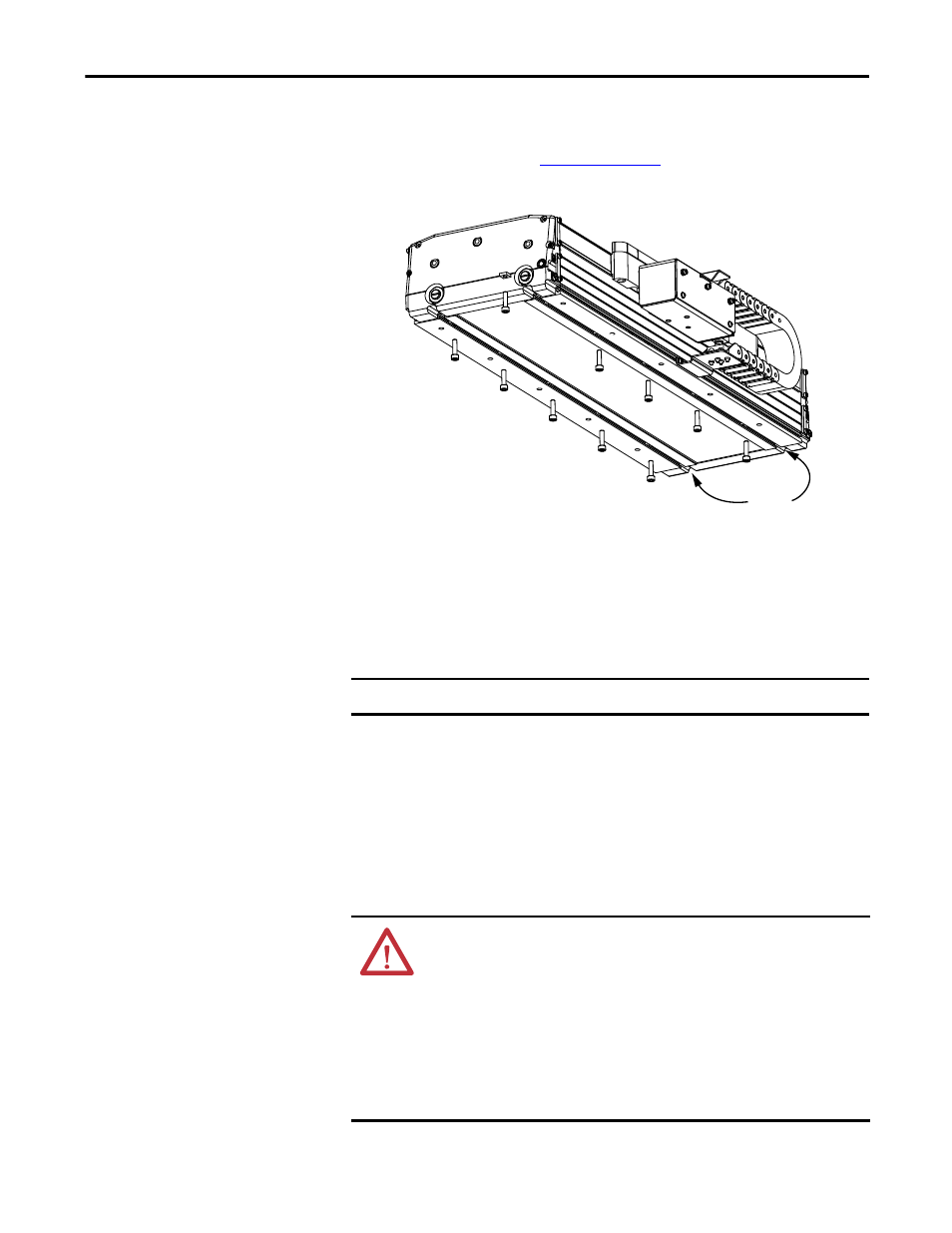

Figure 8 - tee nut mounting, Mounting the stage – Rockwell Automation CHPS-250 Linear Stage Installation User Manual

Page 31

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

31

Mounting the Stage

Chapter 4

Tee nuts are used to mount the stage from underneath. Insert the tee nuts every

120 mm (4.72 in.) in tee slots on the bottom of the unit. Secure the tee nuts by

using M6 SHCS as shown in

diagram.

Figure 8 - Tee Nut Mounting

Mounting the Stage

Follow these steps to install a stage on its mounting surface.

1. Be sure the mounting surface is clear of any and all foreign material.

If necessary, stone the mounting surface (acetone or methanol can be

applied as cleaning agent).

2. Verify that the flatness of the surface that the stage is to be mounted.

The total indicator reading (TIR) is 0.0254 mm (0.001 in.) per 300 mm

(120 in.). TIR or runout, correlates to an overall flatness of a surface.

3. Lift the stage onto the prepared mounting surface

IMPORTANT

Do not use abrasives to clean the surface.

ATTENTION: Do not attempt to move the stage by grasping the cable junction

box. Moving the stage in this manner can damage the stage and create a pinch

or crush hazard. The junction box is attached to the carrier that is free to move.

Lifting the stage in this manner causes uncontrolled movement of the heavy

base. Always use a two person lift and grasp the stage by the base at the end

caps keeping fingers clear of the carrier’s path of travel.

The two lubrication ports on each end cap (four total) are M10 x1.5 tapped through

holes and can be used to install lifting hooks supplied by the customer.

Personal injury and equipment damage can occur if stage is handled improperly.

T-Slots