Component description – Rockwell Automation CHPS-250 Linear Stage Installation User Manual

Page 17

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

17

Understanding Your Stage

Chapter 2

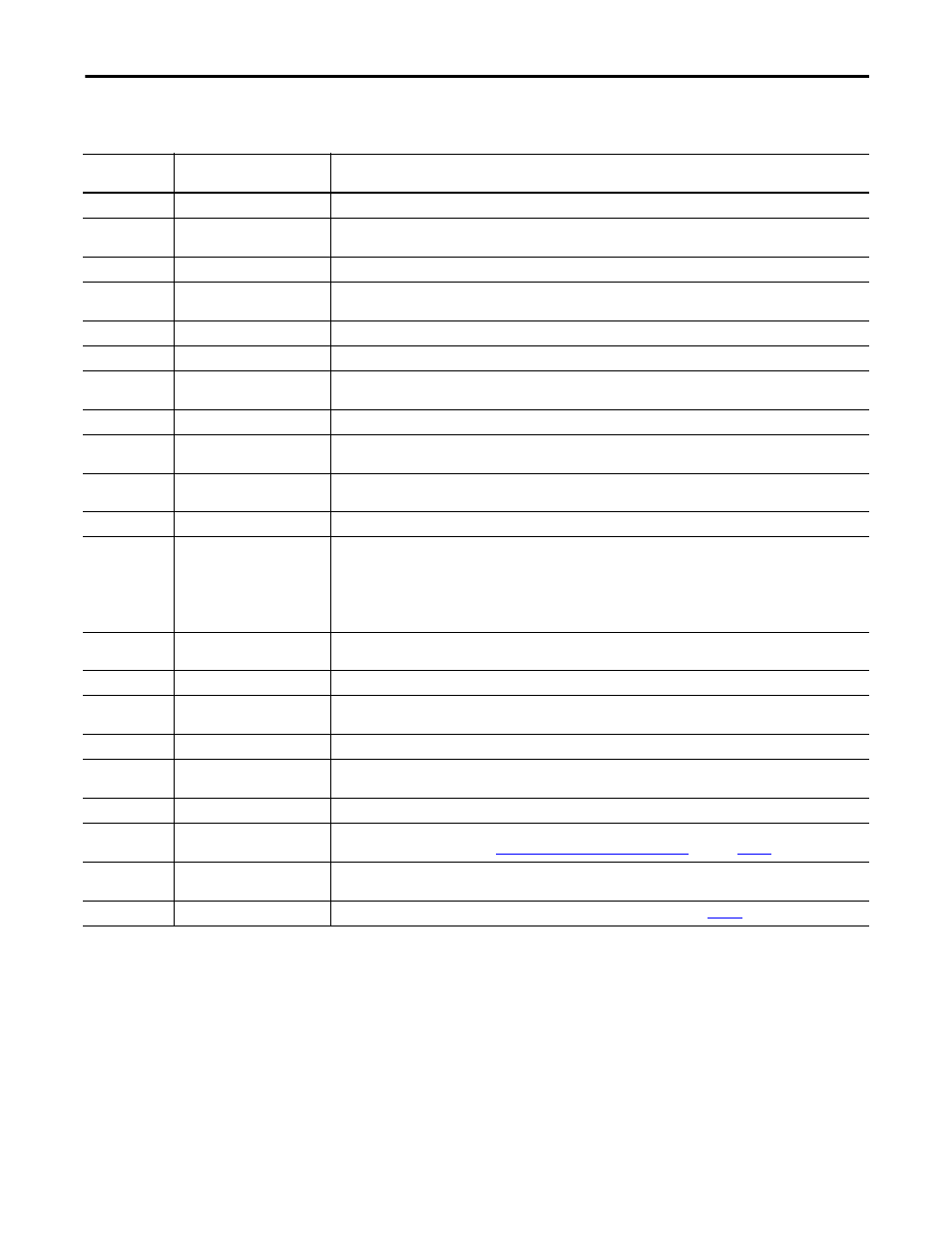

Component Description

Component

Number

Component

Description

1

Ground Screw and Ground Label

Use the labeled M5 x 0.8 - 6H ground screw to connect to the linear stage to a facility safety ground.

2

Bearing Lubrication Ports

These capped ports provide access to the linear bearings without dismantling the stage. In addition these tapped holes

(M10 x 15. -6H) can be used to secure lifting hooks (not provided)

3

Stage Slide

Your application hardware mounts to this slide by using provide mounting holes.

4

Stage Cover

If the strip seals are used this protective cover the stage has magnetic edges to keep the upper edge of the strip seals in

place.

5

Seal Guide

These guides lets the strip seal to move smoothly around the stage slide.

6

Cable Carrier Module

Facilitates quick and easy replacement. Replace the cable carrier module every 10 million cycles.

7

Stage Side Cover

If the strip seals are used this protective cover the stage has magnetic edges to keep the lower edge of the strip seals in

place.

8

Side Cover Support

These supports are used on long stages to stabilize the side cover.

9

Stainless Steel Strip Seal

These replaceable, flexible stainless steel strips permit the stage to move while isolating the internal mechanism of the

stage from environmental contaminants.

10

Strip Seal Clamps

These clamps hold the strip seal in place. When replacing the strip seals, they are used to position it so it lays smooth against

the top and side stage covers.

11

Index Mark

Part of the encoder system that provides a home location for the encoder.

12

Optical Encoder Readhead

This encoder readhead comes in various resolutions and requires little maintenance.

The TTL encoder option provides quadrature incremental position feedback with a differential signal on a RS-422.

The Sine/Cosine encoder option provides a 1 volt peak-to-peak sine and cosine output at a period of 20 μm. The Sine/Cosine

encoder is also known as an analog encoder.

13

Encoder Scale

Part of the encoder system that provides an optical pattern to be read by the encoder readhead. It must be kept free of

contamination for proper operation.

14

Bearing

These support bearings guide the slide on the bearing rail, they require periodic lubrication.

15

Motor Coil

This coil is part of the two piece linear motor. When excited by a linear drive, it generates magnetic forces that interact with

the magnet track creating motion. LC linear motor option shown. LZ linear motors have a different configuration.

16

Bearing Rail

These rails provide the linear track that the slide assembly rides on, they must be kept free of debris.

17

Magnet Track

This track of powerful static magnets is the other half of a linear motor. LC linear motor option shown. LZ linear motor option

has a magnet channel.

18

Limit Blade

Provides a mechanical trigger to the limit sensor.

19

Limit Sensor

These optional sensors output a signal when the limit blade passes in front of them. The position of these sensors can be

adjusted to suit your application, see

Operation Guidelines and Limit Configuration

section on

.

20

Hall Sensor Module

Three Hall sensors in this module are provide for commutation startup and phase alignment. They can also be use for

trapezoidal commutation of the motor.

21

Bumper Stop

These springs absorb slide and payload energy in the event the stage loses control. See

for absorption limits.