Recommended maintenance interval, Identifying your stage – Rockwell Automation CHPS-250 Linear Stage Installation User Manual

Page 18

18

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Chapter 2

Understanding Your Stage

Recommended Maintenance

Interval

Under normal stage use, follow these lubrication guidelines.

Lubricate the stage every 6 months or 2500 km (1550 mi) of travel, which ever

comes first. Use the MPAS grease gun kit and grease cartridge (catalog numbers

MPAS-GPUMP and MPAS-CART respectively). See maintenance section for

lubrication procedures.

Refer to Maintenance beginning on

for lubrication procedures.

Identifying Your Stage

Use the following key to identify the options that your stage is equipped with. Be

sure the information listed on the purchase order correlates to the information on

the packing slip that accompanied your stage components. Inspect the assemblies

and confirm, if applicable, the presence of specified options.

IMPORTANT

You determine the frequency of re-lubrication that is best suited to your

application as an application's environment, motion profile, and duty cycle

can effect the re-lubrication time period required.

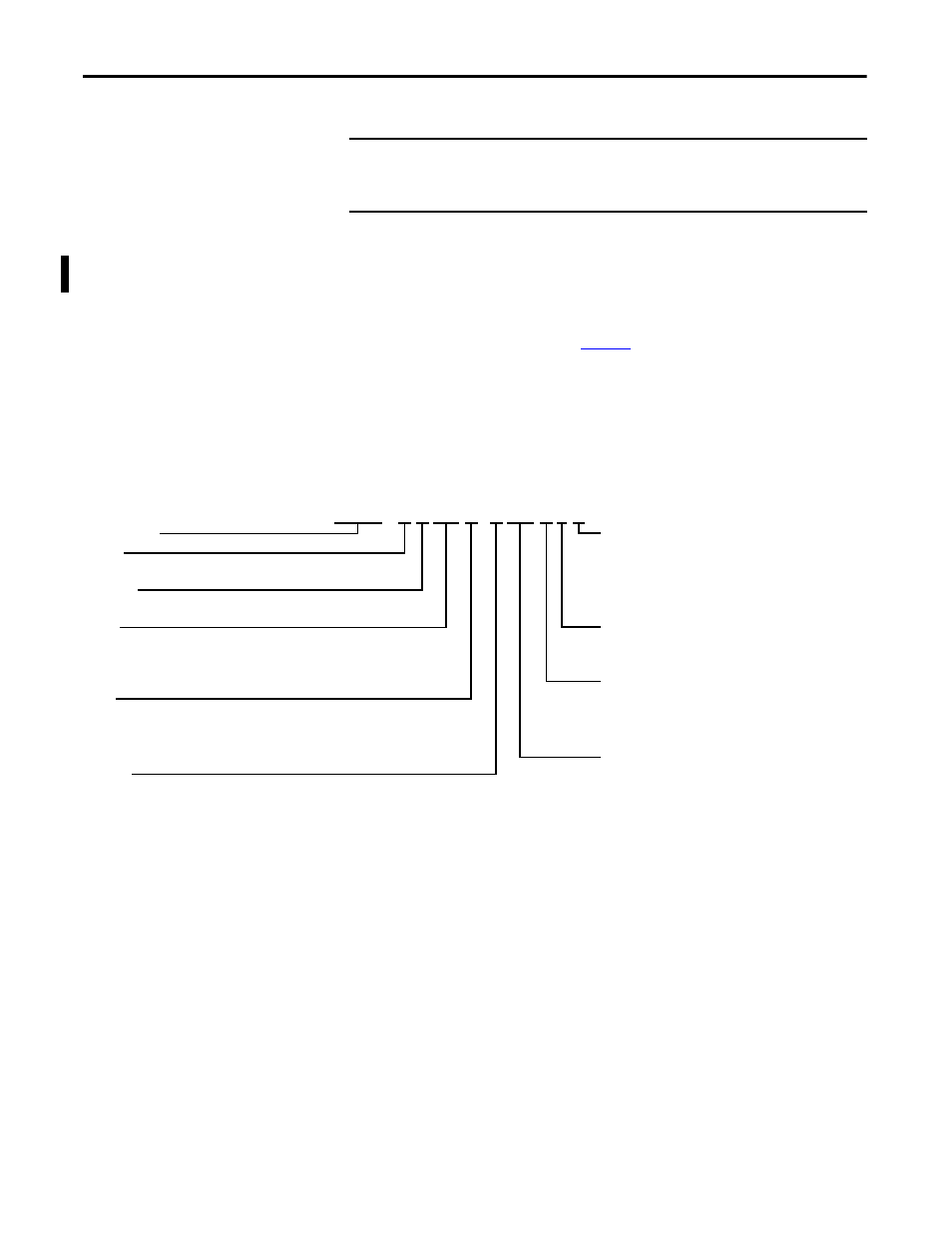

Bulletin Number

Voltage

A= 230V AC

Frame Size

6= 150 mm base

Stroke

Travel lengths start at 6 cm and are available in 6 cm increments.

For example: 006 for 6 cm travel or 054 for 54 cm travel.

Maximum travel = 120 cm.

Motor

A= LZ-030-T-120-D

B= LZ-030-T-240-D

C= LZ-030-T-240-E

Feedback

F= 1.0 micron incremental optical encoder, with integral index mark

G= 0.5 micron incremental optical encoder, with integral index mark

H= 0.1 micron incremental optical encoder, with integral index mark

I= 1V p-p sine/cosine encoder, 20 μm signal period, with integral index mark

CHPS - A 6 054 A - F LM C 2 C

Cable Management and Termination

A = No Cables or Cable Carrier (Slide Junction Box only)

B = Cables with Flying Leads and Cable Carrier

(1)

C = Cables with Kinetix MPF Connectors and Cable Carrier

(1)

D = Cables with D-Connectors and Cable Carrier

(1)

Limits

2 = No limits

5 = Two end of travel limits

Protection

S = Covered with strip seals (IP 30)

(2)(3)

C = Covered without strip seals

(2)

O = Open without any cover, without strip seals

LM Specifier

LM = Linear Motor