Rockwell Automation CHPS-250 Linear Stage Installation User Manual

Page 107

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

107

Mounting Bolts and Torque Values Appendix E

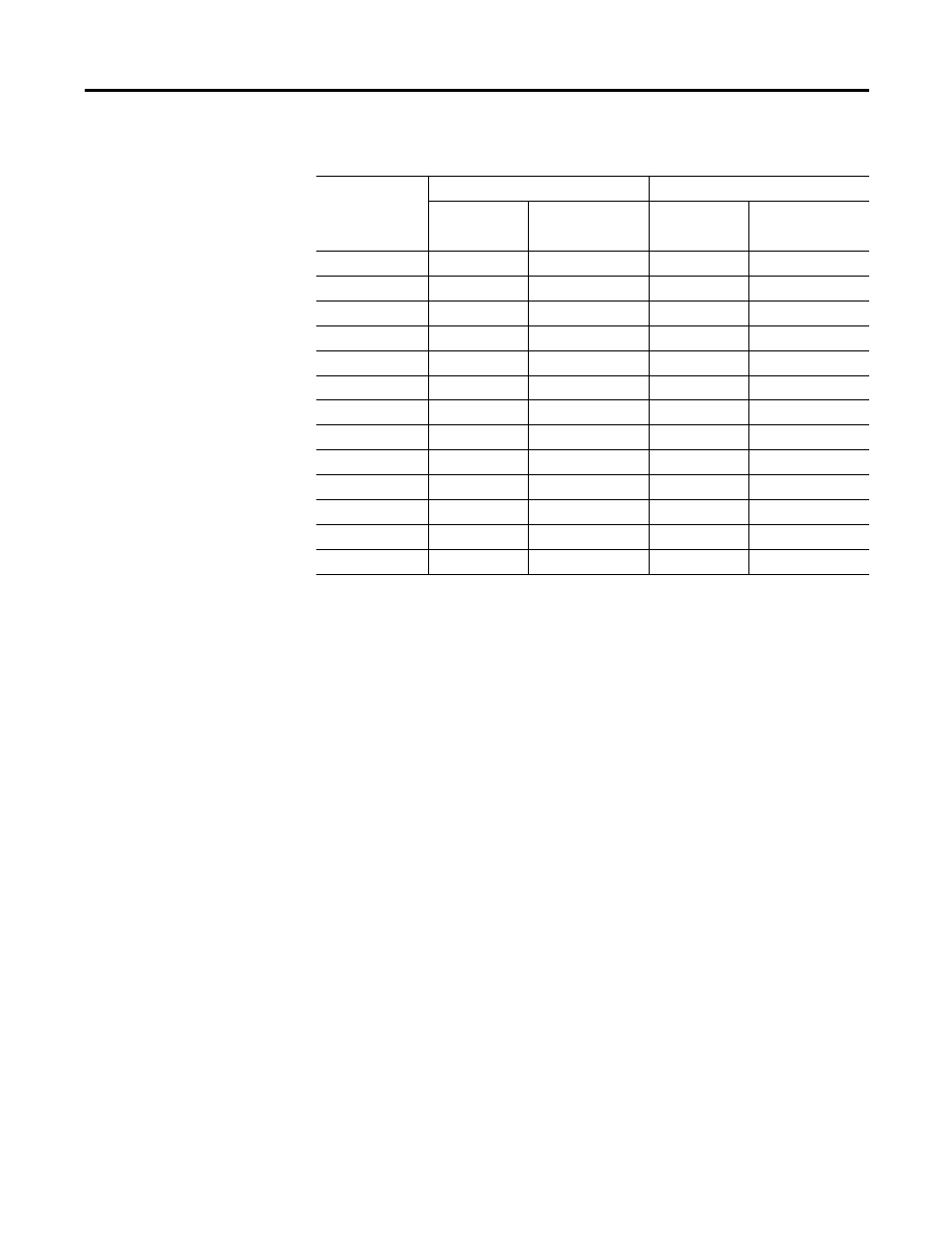

Table 17 - Recommended Seating Torque for Brass Rb 72

UNC

UNF

Plain

Cadmium Plated

Plain

Cadmium Plated

Bolt Size

(1), (2)

N•m (lbf•in)

N•m (lbf•in)

N•m (lbf•in)

N•m (lbf•in)

#0

—

—

0.24 (2.1)

(3)

0.18 (1.6)

(3)

#1

0.43(3.8)

(3)

0.33 (2.9)

(3)

0.46 (4.1)

0.34 (3.0)

(3)

#2

0.71 (6.3)

(3)

0.53 (4.7)

(3)

0.77 (6.8)

(3)

0.58 (5.1)

(3)

#3

1.08 (9.6)

(3)

0.81 (7.2)

(3)

1.16 (10.3)

(3)

0.87 (7.7)

(3)

#4

1.52 (13.5)

(3)

1.1 (10)

(3)

1.67 (14.8)

(3)

1.24 (11)

(3)

#5

2.2 (20)

(3)

1.7 (15)

(3)

2.4 (21)

(3)

1.8 (16)

(3)

#6

2.8 (25)

(3)

2.1 (19)

(3)

3.2 (28)

(3)

2.4 (21)

(3)

#8

5.2 (46)

(3)

3.8 (34)

5.4 (48)

(3)

4.1 (36)

(3)

#10

7.6 (67)

(3)

5.6 (50)

(3)

8.6 (76)

(3)

6.4 (57)

(3)

1/4

15.3 (136)

11.5 (102)

15.4 (136)

11.5 (102)

5/16

25.8 (228)

19.3 (171)

25.8 (228)

19.3 (171)

3/8

53.7 (476)

40.3 (357)

53.7 (476)

40.3 (357)

7/16

76.8 (680)

57.6 (510)

76.8 (680)

57.6 (510)

(1) Mounting hardware is 1960-series socket head cap bolt that meets or exceeds ANSI B18.3.

(2) Torque is based on 60,000 psi bearing stress under the head of the bolt.

(3) Denotes torques based on 100,000 psi tensile stress with threads up to one inch in diameter.