Safe torque-off signal specifications – Rockwell Automation 2097-Vxxx Kinetix 300 EtherNet/IP Indexing Servo Drive User Manual User Manual

Page 168

168

Rockwell Automation Publication 2097-UM001D-EN-P - November 2012

Chapter 8

Kinetix 300 Drive Safe Torque-off Feature

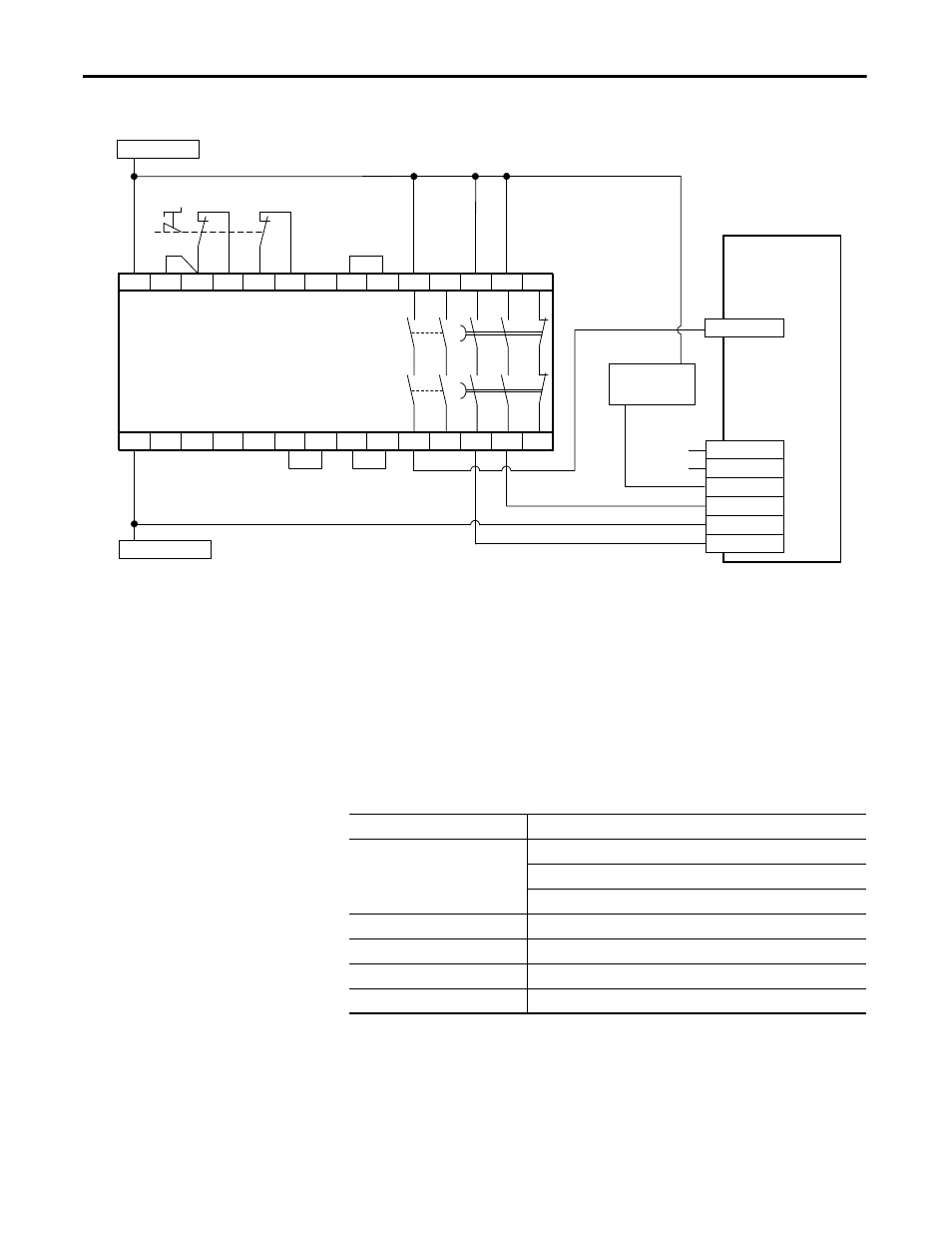

Figure 80 - Single-axis Relay Configuration (Stop Category 1) with Automatic Reset

(1) The digital input, configured for Abort Index in MotionView software, must be active-high when the safety function is requested, so

an interposing relay may be required to invert the signal. Digital input common (IN_x_COM) must be used in this signal activation/

de-activation transition.

You can also bring this input into a PLC where you can use an AOP (add on profile) or assembly object to activate the recommended

digital input (abort index).

Safe Torque-off Signal

Specifications

This table provides specifications for the safe torque-off signals used in the

Kinetix 300 servo drives.

A1

S52

S11

S12

S21

S22

S33

S34

13

23

37

47

57

A2

X1

X2

X3

X4

Y39

Y40

Y2

Y1

14

24

38

48

58

+24V DC

COM

Status

Safety Input 1

Safety Common

Safety Input 2

1

2

3

4

5

6

Allen-Bradley Monitoring Safety Relay

MSR138DP (440R-M23151)

External 24V COM

Safe Torque-off

External +24V DC

Kinetix 300 Drive

Safe Torque-off

(STO) Connector

I/O

(IOD) Connector

Auxiliary Signal

to PLC

Digital Input

(1)

Pins 1 and 2 are not used when using Safety Inputs.

Pin 3 is a sinking output.

Attribute

Value

Safety inputs

(1)

(1) Safety inputs are not designed for pulse testing.

Insulated, compatible with single-ended output (+24V DC)

Enable voltage range: 20…24V DC

Disable voltage range: 0…1.0V DC

Input impedance

6.8 k

Ω

Safety status

Isolated Open Collector (Emitter is grounded.)

Output load capability

100 mA

Digital outputs max voltage

30V DC