1 - overview of safety controllers, Introduction, Safety concept – Rockwell Automation 1755-OF8 GuardPLC Controller Systems User Manual

Page 19: Chapter 1, Overview of safety controllers, Introduction safety concept, Chapter

19

Publication 1753-UM001C-EN-P - March 2010

19

Chapter

1

Overview of Safety Controllers

Introduction

Safety Concept

GuardPLC controllers feature a fail-safe CPU according to IEC 61508

(SIL 3) and ISO 13849-1 (PLe/Cat. 4). Faults that cause loss of safety

function are detected within the safety time you specify. Faults that

cause loss of safety function only in combination with another fault,

are detected at least within the multiple error occurrence time (24

hours).

This results in these requirements for the safety concept:

•

You specify the safety time and the watchdog time. The multiple

error occurrence time is preset to 24 hours.

•

Even upon the detection of an error, the controller continues to

react in a safety-related way.

•

Faulty input signals (for example, incorrectly transmitted input

values) do not affect the safe function of the controller. Faulted

input signals have a 0 value.

•

An error in a non-safety-related module does not affect the

safety of the controller.

•

The failure of the controller has no effect on the safety of other

safety-related modules.

For more information on the safety concept, refer to the GuardPLC

Controllers Safety Reference Manual, publ

.

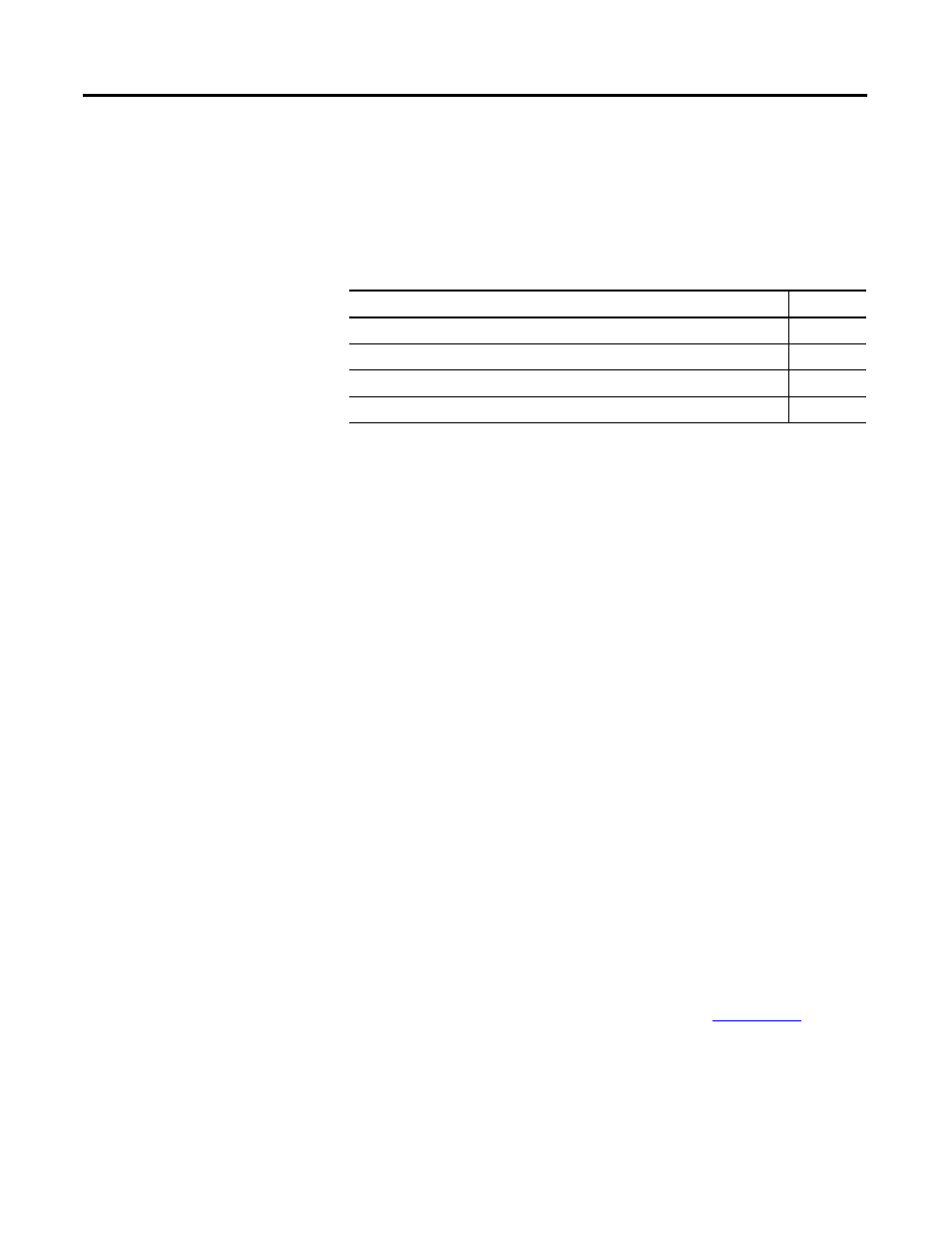

Topic

Page

- 1755-HSC GuardPLC Controller Systems 1755-IF8 GuardPLC Controller Systems 1755-IB24XOB16 GuardPLC Controller Systems 1755-A6 GuardPLC Controller Systems 1755-L1 GuardPLC Controller Systems 1754-L28BBB GuardPLC Controller Systems 1753-IB20XOB8 GuardPLC Controller Systems 1753-OB16 GuardPLC Controller Systems 1753-IB16 GuardPLC Controller Systems 1753-L32BBBP-8A GuardPLC Controller Systems 1753-L32BBBM-8A GuardPLC Controller Systems 1753-L28BBBP GuardPLC Controller Systems 1753-L28BBBM GuardPLC Controller Systems