Dc as shown in figure 2–1 – Rockwell Automation 1336T PLC Comm. Adapter, Series B, FRN 2.xx-3.xx User Manual

Page 39

2–11

Publication 1336 FORCE–5.13 –– September, 1998

Understanding the Scale and Offset Parameters for Input

Analog Input 1 and Analog Input 2 are used in explaining the scale

and offset parameters. At Analog Input 1, between TB21 terminals 9

and 10, a potentiometer with a range of

±

10V

dc has been connected.

Analog Input 1 has been linked to Velocity Reference (parameter

101) in the drive, which gives the potentiometer control of the

external velocity reference.

To calibrate the pot to control 100% base speed in both directions,

you need to adjust the scale parameter. The default value of the scale

parameters allows a total range of 4096, –2048 to +2048. This

allows only 50% base speed in each direction. By setting a scale

factor of 2 in Analog Input 1 Scale, the digital input is multiplied by

2. This provides a range of

±

4096, or 100% base speed in both

directions.

If you want a range of

±

2 times base speed, the scale factor would

be 4 (base speed is 4096, 2 times base speed is 8192, 2048 times 4 is

8192). Analog Input 1 Offset remains at the default value of zero,

allowing the input range to be

±

10V. The range of the offset

parameter is

±

20V

dc as shown in Figure 2–1.

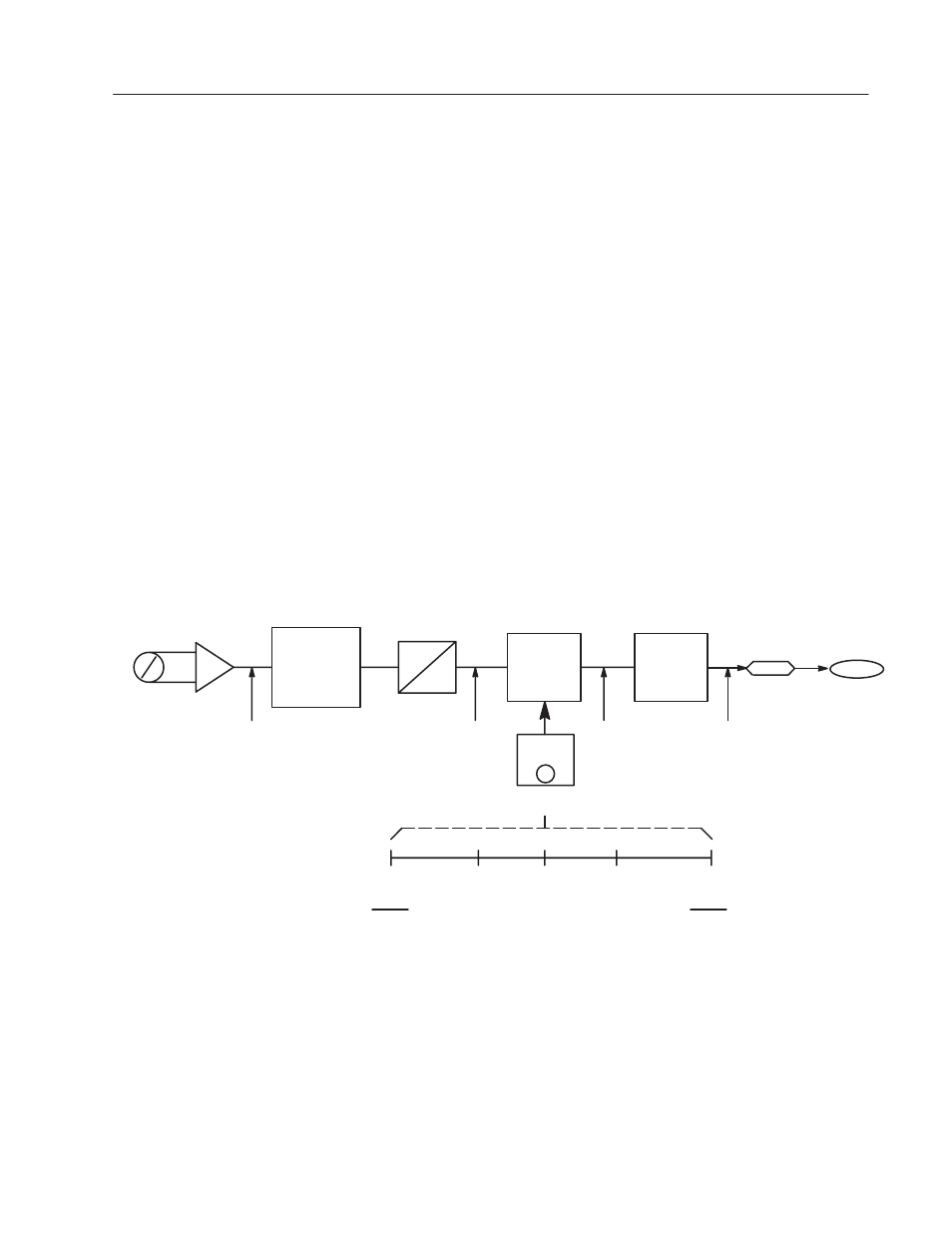

Figure 2.1

Potentiometer with +10V Range to Control 0 to +100% Base Speed

10V Pot

0

–10V

Multiplexer

A

D

Scale

Par 339

+2048

0

–2048

+2048

0

–2048

+4096

0

–4096

Offset

Par 392 = 0

Range of 20V

0

0

0

0

–10V

–2048

X 2

–4096

+10V

+2048

X 2

+4096

Par 393

X 4

+

+10V

Potentiometer

Digital Value

Scale

Final Value Par 401

Par 104

Analog In 1

Velocity

Reference 2

Hi

+ 2048

(= + 10V)

For Analog Input 2, a 0 to 10 volt potentiometer is used to adjust the

Torque Reference from –100% to +100%. To do this, you need to

adjust both the scale and offset parameters. By linking Analog Input

2 to Torque Reference (parameter 162), the potentiometer connected

to Analog Input 2 becomes the Torque Reference Signal. This signal

must be scaled and offset to get the entire

±

100% in the 0 through 10

volt range. A digital range of 8192 (

±

4096) must now be scaled for

an analog range of 10 volts, and must be offset so 5 volts on the

potentiometer indicates 0% Torque.