3 terminology used, Terminology used, 1about this documentation – Lenze 8400 BaseLine D User Manual

Page 10

1

About this documentation

1.3

Terminology used

10

Lenze · 8400 BaseLine D · Reference manual · DMS 5.5 EN · 01/2014 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3

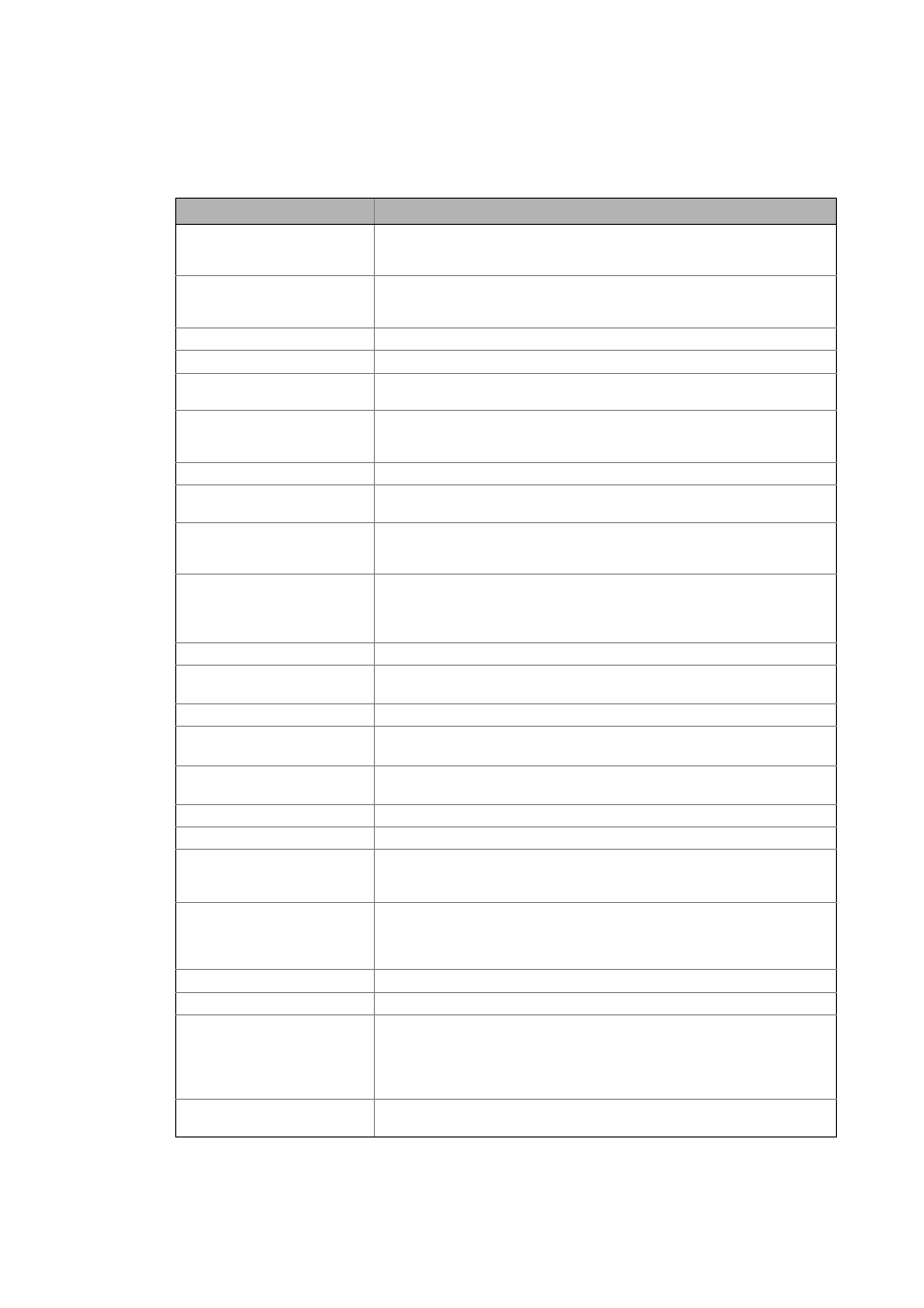

Terminology used

Term

Meaning

»Engineer«

Lenze PC software which supports you in "engineering" (parameterisation, diag-

nostics and configuration) throughout the whole life cycle, i.e. from planning to

maintenance of the commissioned machine.

Application

A technology application is a drive solution equipped with Lenze's experience

and know-how in which function and system blocks interconnected to a signal

flow are the basis for implementing typical drive tasks.

ASM

Asynchronous motor

CINH

Abbreviation: Controller inhibit (pulse inhibit)

Code

Parameter used for controller parameterisation or monitoring. The term is usu-

ally called "index".

DC-injection braking

DC injection braking is to brake and/or hold the motor. For this purpose, the

8400 BaseLine D creates a quasi DC field at the stator of the asynchronous ma-

chine. The energy to be dissipated is converted into heat in the rotor.

DCTRL

Abbreviation: Drive control (device control)

Display code

Parameter that displays the current state or value of an input/output of a sys-

tem block.

EPM

Memory module on which all parametes of the drive system are saved non-vola-

tilely. These include the parameters of the controller and communication-rele-

vant parameters for the communication unit used.

Function block

A function block can be compared with an integrated circuit that contains a cer-

tain control logic and delivers one or several values when being executed.

• Each function block has a unique identifier, e.g. "L_MPot_1" (motor potentio-

meter function)

Holding brake

The holding brake serves to hold the rotor by means of a mechanical unit.

LA

Abbreviation: Lenze Application block

• Example: "LA_NCtrl" – block for the "actuating drive speed" application.

Lenze setting

This setting is the default factory setting of the device.

LP

Abbreviation: Lenze Port block

• Example: "LP_Network_In" – port block for fieldbus communication.

LS

Abbreviation: Lenze System block

• Example: "LS_DigitalInput" – system block for digital input signals.

MCTRL

Abbreviation: Motor control

Port block

Block for implementing the process data transfer via a fieldbus

QSP

Quick stop ("Quick stop):

The motor control is decoupled from the setpoint selection and within a parame-

terisable deceleration time, the motor is brought to a standstill (n

act

= 0).

Service brake

The service brake serves to shutdown rotary or translatory masses in motion in

a controlled manner. The energy to be dissipated in this process is converted into

heat in the form of friction energy. This process is a regular and recurring opera-

ting mode.

SLVC

Motor control: Sensorless vector control ("SensorLess Vector Control")

SM

Synchronous motor

Subcode

If a code contains several parameters, the individual parameters are stored un-

der "subcodes".

This manual uses a slash "/" as a separator between code and subcode

(e.g. "C118/3").

The term is usually called "subindex".

System block

In the application, system blocks provide interfaces to basic functions and to the

hardware of the controller (e.g. to the digital inputs).