4 optimising the positioning behaviour – Festo Контроллер крайних положений SPC11 User Manual

Page 117

5. Diagnosis and error treatment

5-9

Festo P.BE-SPC11-SYS-EN en 1406e

5.4

Optimising the positioning behaviour

After the “teach” procedure the positioning behaviour is

automatically optimised in the first 20 to 30 strokes by means

of internal adaptation. If the quality of the positioning behav-

iour still does not fulfil expectations, proceed as follows:

–

Check the parameters A, C, and S (see “Drive-Specific

Supplement” for the drive used).

–

Check whether the installation of the pneumatic compo-

nents fulfils the demands listed in section 3.2. Make sure

especially that the supply pressure is stable, that the tub-

ing is of the correct length and diameter and that the cor-

rect screw connectors are used.

–

Check the set options (o-parameters). The following op-

tions influence positioning behaviour (see section 4.2.3):

–

constant adaptation on/off

–

soft end position behaviour on/off.

If, however, the moveable mass still moves into the end posi-

tions with too hard an impact, or brakes too heavily before

reaching the end position, you can optimise the positioning

behaviour by increasing or reducing the cushioning level

and/or the amplification level.

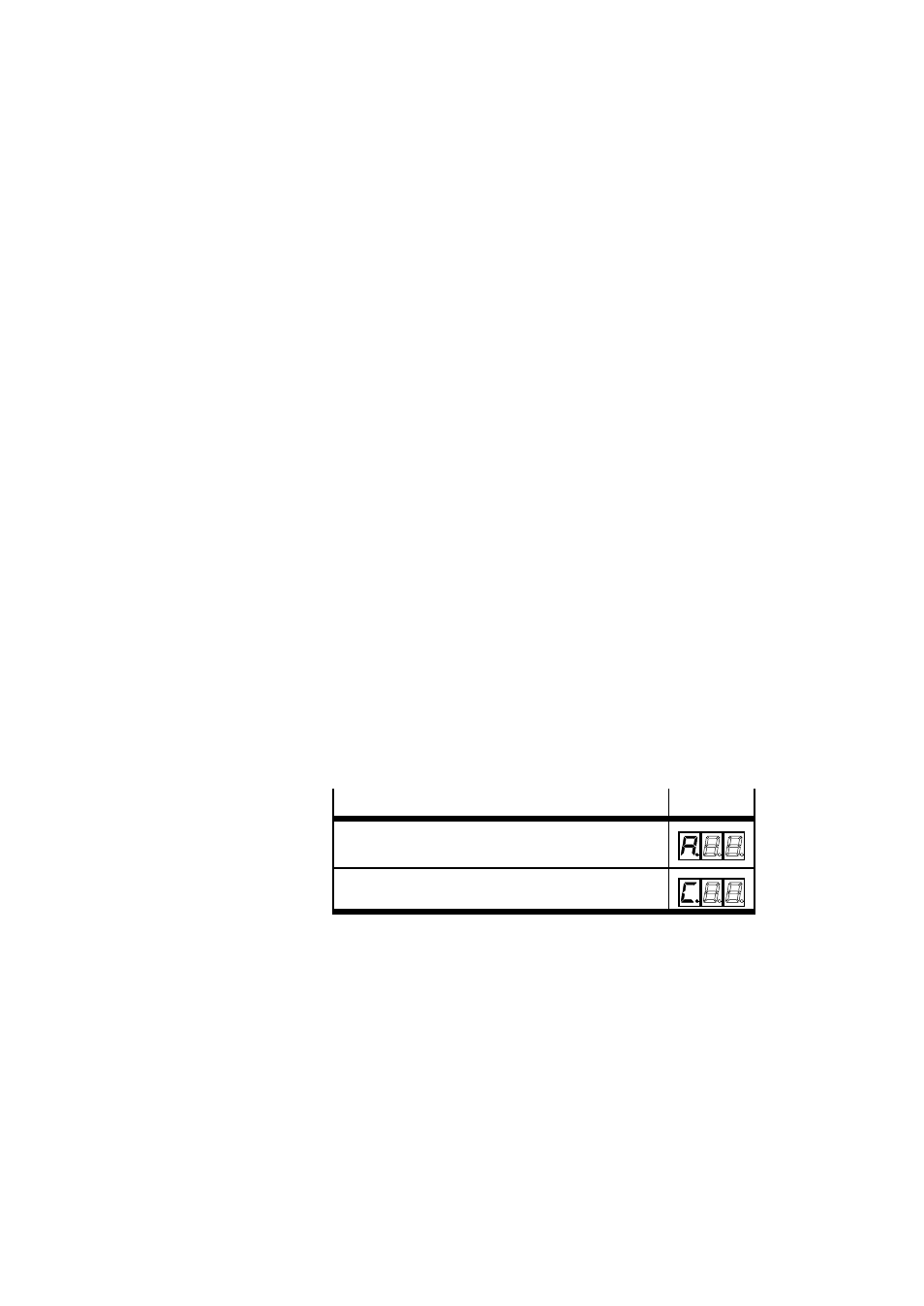

Control parameter stage

Display

Amplification stage

Cushioning stage