Festo Контроллер крайних положений SPC11 User Manual

Page 112

5. Diagnosis and error treatment

5-4

Festo P.BE-SPC11-SYS-EN en 1406e

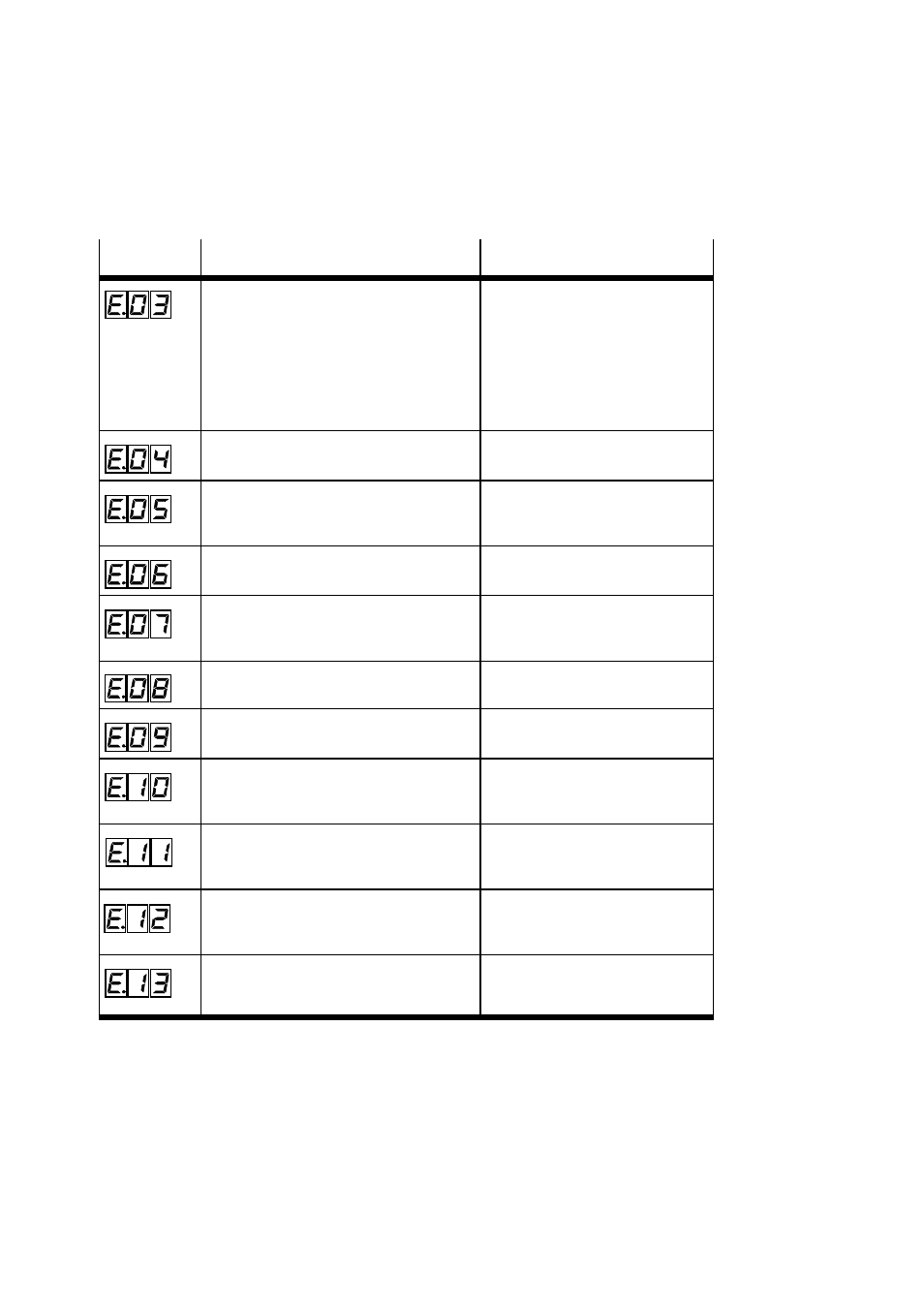

Fault no.

Eliminating faults

Operating status

Offset fault in the static identification:

– Too little stiffness in the fixed stop

– Proportional directional control valve

defective

– External fluctuating force on the slide

during identification travel

S

Ensure stiffness of the fixed stop

(e.g. remove cushioning plate of

the DSMI-...)

S

Replace proportional directional

control valve

S

Use the constant external force

during identification travel

No movement during static identification or

reference travel

S

Check the compressed air supply

and the tubing

Overswing fault during dynamic identifica-

tion due to incorrect amplification stage,

cushioning stage or system parameter

S

Check and correct the amplifica-

tion stage, cushioning stage and

system parameter

Amplification stage, cushioning stage or

system parameter set incorrectly

S

Correct parameters

The measuring system has no valid length

code (non-permitted measuring system

length or length code does not exist)

Servicing is required

SPC11 damaged (EEPROM-ACK fault)

S

Replace the SPC11

Measuring system type is not recognised

(invalid measuring system ID read in)

S

Replace the SPC11

Communication to measuring system is

faulty (non-plausible data has been

received)

S

Check the measuring system

length or replace the measuring

system

Communication to measuring system is

faulty (non-plausible data has been

received)

S

Check the measuring system

length or replace the measuring

system

Incorrect direction of movement ascertained

during positioning stroke; tubing is

incorrectly connected

S

Correct the tubing of the propor-

tional directional control valve

Allowed time exceeded; the position cannot

be reached fast enough (positioning timeout

approx. 10 s)

S

Remove obstruction in positioning

path or check compressed air

supply