Festo Контроллер крайних положений SPC11 User Manual

Page 115

5. Diagnosis and error treatment

5-7

Festo P.BE-SPC11-SYS-EN en 1406e

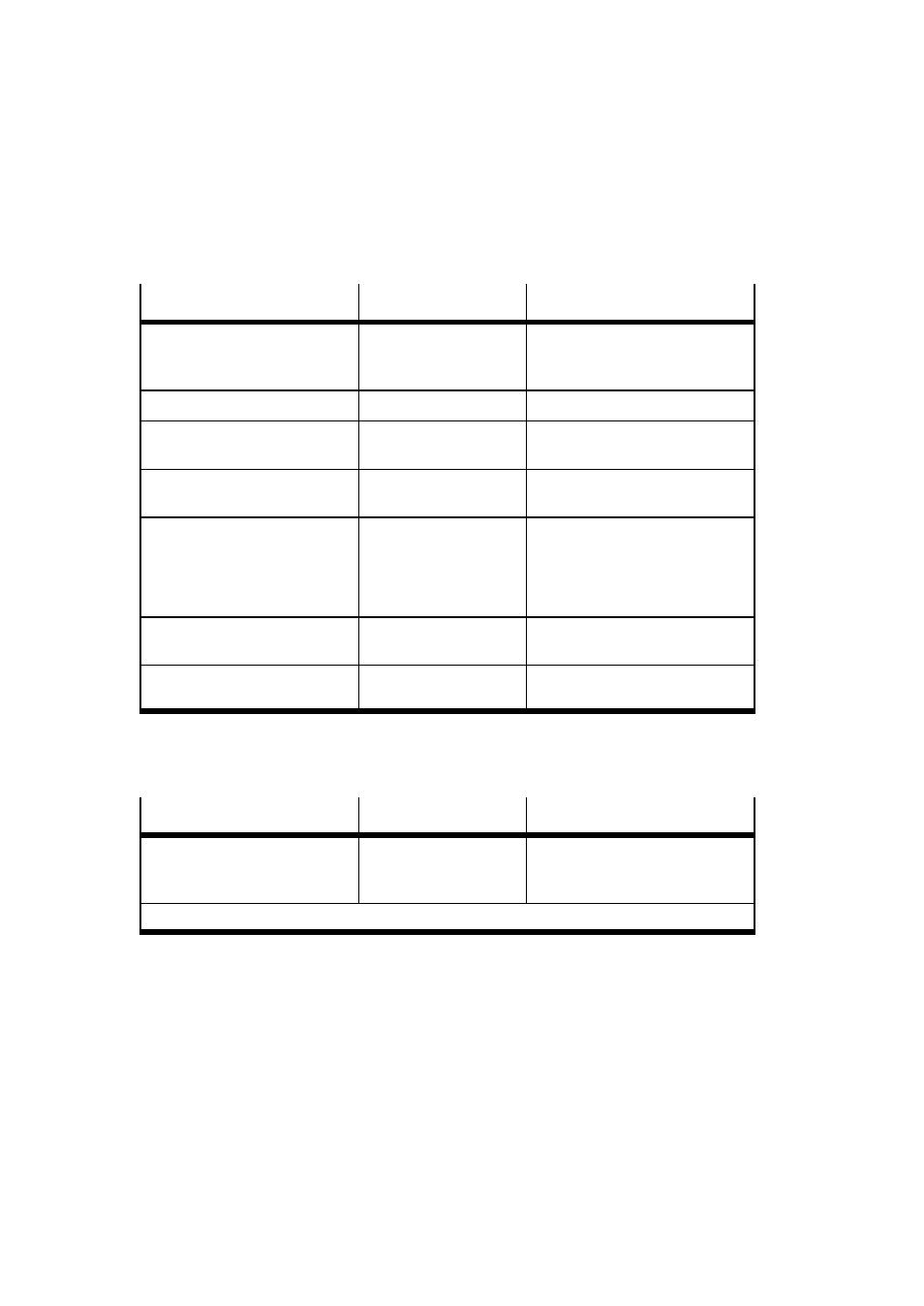

2) Bad behaviour during movement to end position

Cause

Remedy

Remarks

System is not mounted correctly

Check fitting and

mechanical parts

Check measuring system and drive

for parallelism, mechanical play

and sluggishness

System is not earthed correctly

Check

See chapter 3

Parameters are not set optimally

Check parameters

See “Drive-Specific Supplement”

manual

High fluctuations in supply

pressure (› 0.5 bar)

Check the supply

pressure

If necessary, fit a compressed air

reservoir.

Non-permitted mass load

Check mass load and

parameters

If necessary, place a basic load in

position, in order that the maximum

permitted value range is not

exceeded during positioning with

different masses.

During too fast/hard movement

into the end positions

Increase the cushioning

stage (parameter C)

See section 5.4

During too slow/soft movement

into the end positions

Reduce the cushioning

stage (parameter C)

See section 5.4

3) Mass moves to end position without a command

Cause

Remedy

Remarks

Proportional directional control

valve is defective

Check and, if necessary,

replace proportional

directional control valve

You can check through the viewing

window to see if the valve slide

jams.

1)

1)

See operating instructions for valve MPYE-5-...