Micromod RetroPAK: SLC Configuration Manual User Manual

Page 171

Command Series Migration to MOD 30ML

Pre-Configured – Cascade Control

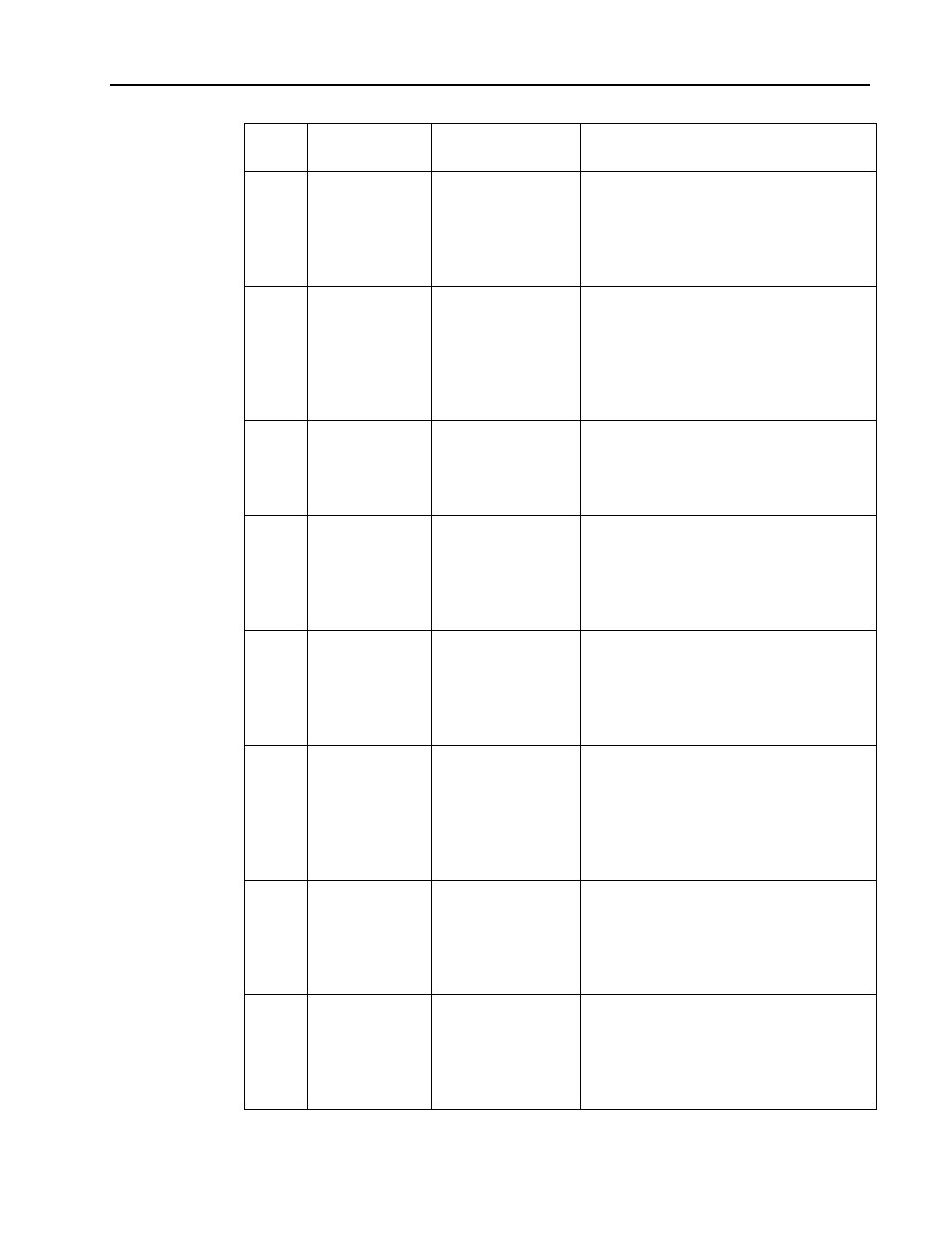

GAIN MULTIPLIER INPUT.

S11

PID2

Input – S11

Floating Point

Gain Multiplier input for the PID2.

Connect to the PID2.S11 signal of the

compound or change in the Control tab

of the PID2 block. Change the value for

GAIN MULTIPLIER INPUT.

S11

PIDFAIL

Input – S11

Floating Point

Gain Multiplier input for the failover

PID (PIDFAIL). Connect to the

PIDFAIL.S11 signal of the compound

or change in the Control tab of the

PIDFAIL block. Change the value for

GAIN MULTIPLIER INPUT.

S12

ENG

Input – GAIN_1,

GAIN_2, GAIN_F

Floating Point

Proportional Gain Kp. Enter in the ENG

block. Open the Inputs tab and select the

respective input (GAIN_1, GAIN_2,

GAIN_F) to change the value.

S13

ENG

Input – RESET_1,

RESET_2,

RESET_F Floating

Point

Integral Reset in resets/min (RPM) Ki.

Enter in the ENG block. Open the

Inputs tab and select the respective input

(RESET_1, RESET_2, RESET_F) to

change the value.

S14 ENG

Input

–

PREACT_1,

PREACT_2,

PREACT_F

Floating Point

Derivative rate in minutes Kd. Enter in

the ENG block. Open the Inputs tab and

select the respective input (PREACT_1,

PREACT_2, PREACT_F) to change

the value.

S15 PID1,

PID2,

PIDFAIL

Input – S15

Floating Point

Derivative Lag constant Ka. Enter the

value in the respective PID block. Open

the Control tab and change the INPUT

FILTER TPE to PRE-ACT USER and

type the value in the INPUT FILTER

TIME field.

S16 PID1,

PID2,

PIDFAIL

Input – S16

Floating Point

High Output Limit. Enter the value in

the respective PID block. Open the

Output tab and change the OUTPUT

LIMITS HIGH field and OUTPUT

RANGE HIGH field.

S17 PID1,

PID2,

PIDFAIL

Input – S17

Floating Point

Low Output Limit. Enter the value in

the respective PID block. Open the

Output tab and change the OUTPUT

LIMITS LOW field and OUTPUT

RANGE LOW field.

P5- 3