Explanation, Inputs – outputs – Micromod RetroPAK: SLC Configuration Manual User Manual

Page 108

Command Series Migration to MOD 30ML

Pre-configured Dual Loop PID Control

EXPLANATION

Configuration with this compound requires understanding of the compound and how the

PID block is configured in the MOD 30ML/Modcell controllers. Following is the

reference that includes listing of most commonly used / changed attribute and inputs and

outputs. Necessary block configuration tabs are also explained to make it easier.

INPUTS – OUTPUTS

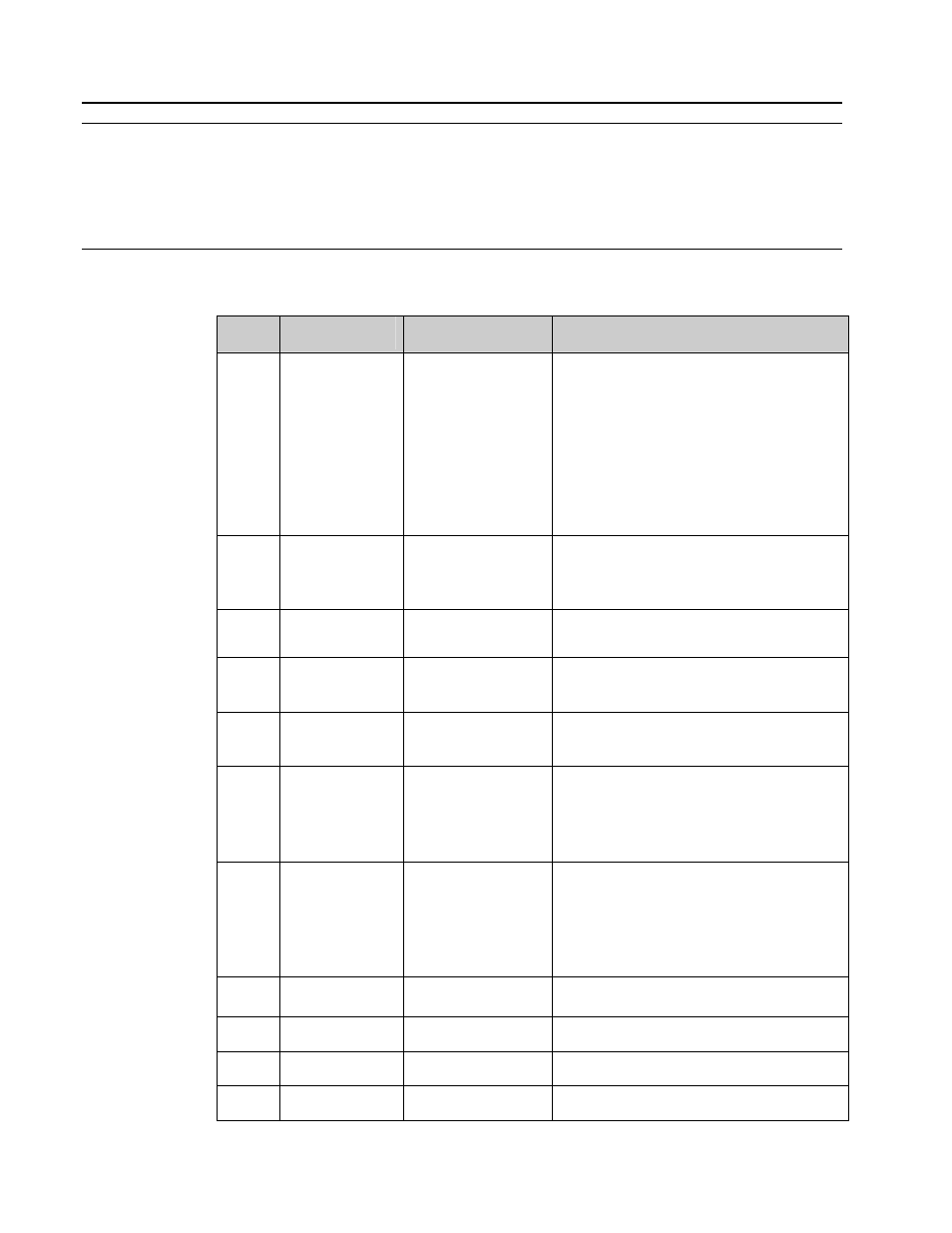

The I/O table is identical to both the loop compounds.

Signal Block

Type

Description

S1

PID

Input – S1

Floating Point

Result (R) of the VCI block VCI-1 is

already connected to PID.S1 signal of

the compound for the first loop.

Result (R) of the VCI block VCI-2 is

already connected to PID.S1 signal of

the compound for the second loop.

Process Input signals.

S1Q

QUALLOGIC

Output – S1Q

Boolean (Discrete)

Connect to the QUALLOGIC.S1Q

signal of the compound. Process Input

Quality

S2 N/A

N/A

N/A

S3

PID

Input – S3

Floating Point

Connect to the PID.S3 signal of the

compound. Track Reference.

S4

PID

Input – S4

Boolean

Connect to the PID.S4 signal of the

compound. Track Switch.

S5

PID

Input – Floating

Point

Change in the Control tab of the

corresponding PID block. Change the

value for MANUAL RESET – BASE

VALUE.

S6

PID

Input – S6

Floating Point

Feed-forward input for the PID. Enable

in the Options tab of the PID block.

Change the calculation type to Add.

Connect the feed forward input to the

PID.S6 signal of the compound.

S7 N/A

N/A

N/A

S8 N/A

N/A

N/A

S9 N/A

N/A

N/A

S10 N/A

N/A

N/A

P2- 2