Table 10-3. proportional cycle method, Table 10-3 – Micromod Micro-DCI: 53SL5100A Single Loop Controller User Manual

Page 109

Single Loop Process Controller Instruction Manual

Instrument Tuning 101

12

lntroduce automatic reset slowly by decreasing TR (C107) until cycling starts.

13

Back off TR (C107) to a safe margin of about 1.5 times the value attained in Step 12.

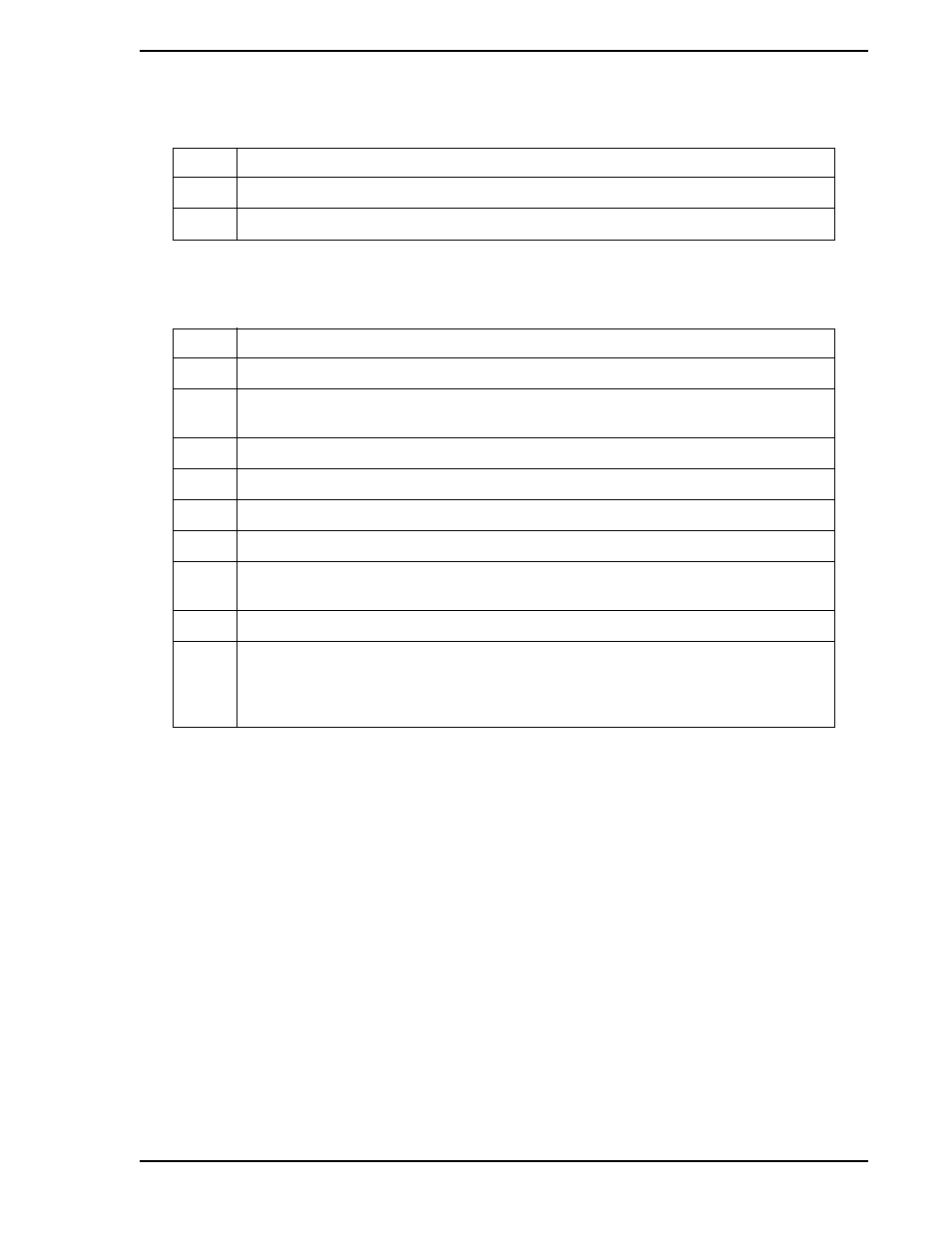

Table 10-3. Proportional Cycle Method

Step

Procedure

1

Set the process to approximately normal conditions in Manual mode.

2

Set TR (C107) first to minimum value (0.02 minutes) for several moments, then set it

to extreme maximum (200 minutes) to lock in a fixed reset value.

3

Set P.B. (C106~ to the widest value 1000%).

4

Set TD (C108) to the lowest value (0.01 minutes).

5

Switch to Auto mode.

6

Slowly reduce P.B. (C106) until process cycling starts.

7

When a slight cycle is repeatedly established, measure the peak-to-peak period of

oscillation and record it as T minutes.

8

Observe the P.B. setting and record it as P.

9

Compute the best settings as follows:

A. Proportional & Integral (PI): P.B. = 2 (P), TR = 0.8(T)

B. Proportional & Derivative (PD): P.B. = 0.8(P), TD = 0.12(T)

C. Proportional, Integral, and Derivative (PID): P.B. = 1.5(P), TR = 0.5(T), TD = 0.12(T)

Table 10-2. Trial and Error Tuning Method (Continued)

Step

Procedure

- Micro-DCI: EP1000A E-Port (56 pages)

- Micro-DCI: 53SL6000 Single Loop Controller (138 pages)

- Micro-DCI: 53SL5100B Single Loop Controller (115 pages)

- Micro-DCI: 53ML5100 Manual Loader (49 pages)

- Micro-DCI: 53MC5000 PLC AND PRINTER INTERFACES (124 pages)

- Micro-DCI: 53MC5000 MicroLink (33 pages)

- Micro-DCI: 53MC5000 Multi-Loop Process Controller Installation (99 pages)

- Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual (406 pages)

- Micro-DCI: 53MC5000 Multi-Loop Process Controller FLEXIBLE CONTROL STRATEGIES (201 pages)

- Micro-DCI: 53MC5000 Multi-Loop Process Controller CUSTOMIZATION GUIDE (123 pages)

- Micro-DCI: 53IT5100B Micro-DCI 4-Channel Indicator Totalizer (71 pages)

- Micro-DCI: 53MC5000 Training Manual (180 pages)

- Micro-DCI: 53SL5100A Single Loop Controller Rev. 1 Firmware (6 pages)

- Micro-DCI: 53ML5100A LOADING STATION REV. 1 FIRMWARE (20 pages)

- Micro-DCI: 53ML5100A LOADING STATION (55 pages)

- Micro-DCI: 53IT5100A Indicator/Totalizer Rev. 1 Firmware (4 pages)

- Micro-DCI: 53IT5100A Indicator/Totalizer (80 pages)

- MOD: 2001P - MODCELL Logic Control Identity Module (Version 6) System, I/O and Communications Functions (272 pages)

- MOD: 2001P - MODCELL Logic Control Identity Module (Version 6) Algorithms, Tables and Sequential Logic Functions (160 pages)

- MOD: 2004P - MODCELL Continuous Control Identity Module (Version 3) PID and Ramp/Soak Functions (70 pages)

- MOD: 30ML and Modcell Totalization Application Guide (24 pages)

- MOD: 30ML and Modcell Maintenance for 2001N, 2002N, and 1800R (152 pages)

- MOD: Remote I/O Modules for use with 2020N Remote I/O Interface Module (42 pages)

- MOD: MODCELL Multiloop Processor 2002N Model C and Associated Hardware (82 pages)

- MOD: 30ML Installation (106 pages)

- MOD: 30ML Replacement for MOD30 Instruments (36 pages)

- MOD: 30ML Installation for Replacing SLC/CLC Instruments (68 pages)

- MOD: 30ML Function Code Configuration Guide for Replacing SLC/CLC Instruments (394 pages)

- MOD: 30ML Operation and Template Setup (84 pages)

- MOD: 30ML Functions Data Base Reference (152 pages)

- MOD: 30ML Display Script Guide (98 pages)

- MOD: 30ML FrontFace Configuration Charts (6 pages)

- MOD: 30ML Quick Reference Guide (2 pages)

- MOD: 30ML Controller Operation and Maintenance Training Manual (74 pages)

- MOD: Modcell 2050R Users Guide (228 pages)

- MOD: Modcell 2050R MODBUS Communications (70 pages)

- MOD: Modcell 2050R Quick Reference Guide (2 pages)

- MOD: Modcell 2050R Mounting Dimensions (1 page)

- MOD: Modcell 2050R 2050FZ0, QS-1300/1400 to 2050R Conversion Accessory (10 pages)

- MOD: Modcell 2050R 2051FZ2, Foxboro 62H to 2050R Conversion Accessory (4 pages)

- MOD: Modcell 2050R 2051FZ1 and 2051FZ1, Foxboro SPEC 200 to 2050R Conversion Accessory (4 pages)

- MOD: 1731N ICN Mini-Link Users Guide (28 pages)

- MOD: 1732N, 1733N External Mini-Link Users Guide (22 pages)

- MOD: ICN OPC Server Users Guide (38 pages)