Modbus com settings on aerco devices (rer or ler), Aerco protonode gateway – AERCO ProtoNode Gateway Rev 3 (with external LEDs) User Manual

Page 8

AERCO ProtoNode Gateway

User Manual

Page 8 of 126

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0080_0H

11/06/2014

Ph.: 800-526-0288

GF-129

2.3 MODBUS COM SETTINGS ON AERCO DEVICES (RER OR LER)

2.3.1 Set Modbus COM Setting On All Devices Connected to the ProtoNode

All devices connected to the ProtoNode host port MUST ALL have the same Baud Rate,

Data Bits, Stop Bits, and Parity.

• Baud Rate = 9600

• Data Bits = 8

• Stop Bits = 1

• Parity = None

Be sure the following settings in the respective AERCO units are as indicated below:

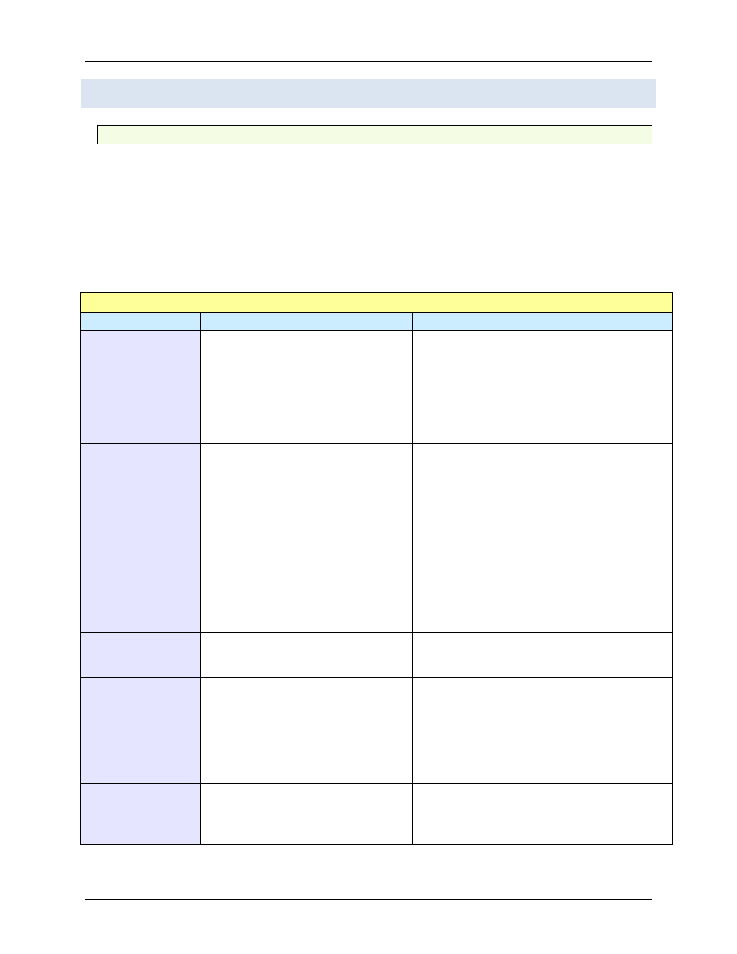

TABLE 2-2: Modbus COM Settings for AERCO Devices

Connected To:

To Monitor Only

To Monitor and Control

ACS/BMS II

RS232 Mode =

Modbus Slave

RS232 Baudrate = 9600

Modbus Address = 128

To Monitor Boilers:

Modbus Pass thru = Enabled

For remote setpoint control via Modbus,

in addition to the “Monitor Only” settings,

set:

Header Set Mode = Remote Setpt

Remote Signal: = Network

C-More: Boiler or

Heater without

WHM or BST

Comm. Address = 1 to 4,

or 1 to 8,

or 1 to 12,

depending on the configuration

selected.

Baudrate = 9600

For remote setpoint control via Modbus,

in addition to the “Monitor Only” settings,

set:

Boiler Mode = Remote Setpt

Remote Signal: = Network

For Direct Drive control via Modbus in

addition to the “Monitor Only” settings,

set:

Boiler Mode = Direct Drive

Remote Signal: = Network

MLX Boiler with

BCM

Address DIP switches = 1 to 4

Same setup as “Monitor Only”

SmartPlate or

ECS Heater

Addr = 29 to 32

For Remote Setpoint control via Modbus,

in addition to the “Monitor Only” settings,

set:

Rmt = SP

L-r = rmt

C-More Heater

with WHM or

Boiler with BST

SSD Address = 247

Same setup as “To Monitor Only”