Using this manual preface, Command blocks, Status blocks – Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 9

Using this Manual

Preface

P-3

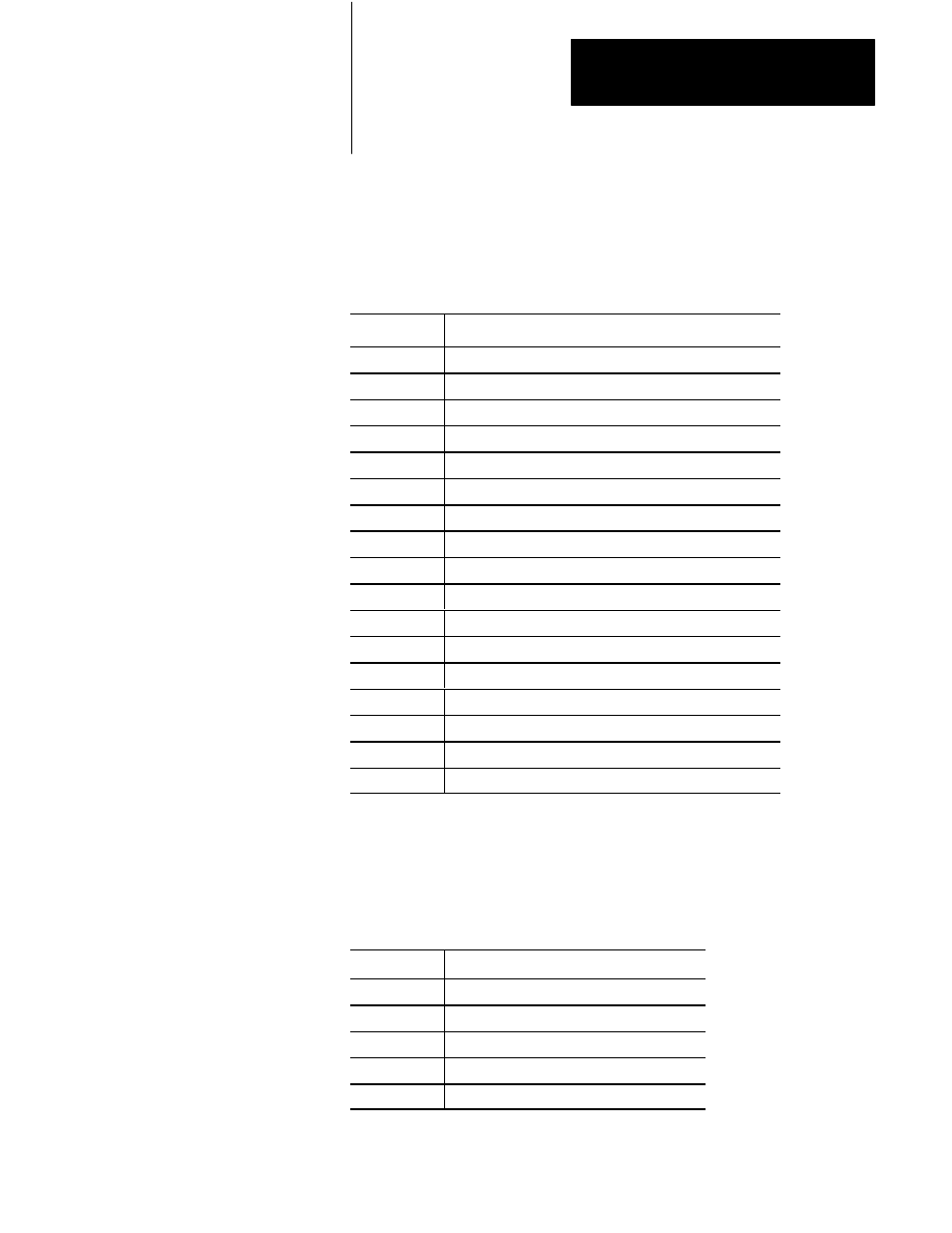

Command Blocks

Command blocks provide the parameters that control machine operation.

Command blocks are transferred from the PLC processor to the QDC

module by means of block transfer write (BTW) instructions in software

ladder logic. Command block abbreviations are:

Acronym:

Description:

MCC

Module Configuration Block

JGC

Jog Configuration Block

FCC

First Clamp Close Configuration Block

SCC

Second Clamp Close Configuration Block

TCC

Third Clamp Close Configuration Block

LPC

Low Press Clamp Close Configuration Block

CPC

Clamp Close Profile Block

FOC

First Clamp Open Configuration Block

SOC

Second Clamp Open Configuration Block

TOC

Third Clamp Open Configuration Block

OSC

Clamp Open Slow Configuration Block

OPC

Clamp Open Profile Block

EAC

Ejector Advance Configuration Block

ERC

Ejector Retract Configuration Block

EPC

Ejector Profile Block

DYC

Dynamic Command Block

CLC

Clamp & Eject ERC Values Block

Status Blocks

Status blocks report current status of molding-machine operation. Status

blocks are returned from the QDC module to the PLC processor by means

of block transfer read (BTR) instructions in software ladder logic. Status

block abbreviations are:

Acronym:

Description:

SYS

System Status Block

CPS

Clamp Close Profile Status Block

OPS

Clamp Open Profile Status Block

EPS

Ejector Profile Status Block

CLS

Clamp & Eject ERC Values Status Block