Chapter objectives, Load initial profile values for machine tuning – Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 115

Chapter

8

8-1

Load Initial Profile Values for

Machine Tuning

In the previous chapters, you entered information into configuration blocks

necessary for your clamp and eject profiles to run properly. This chapter

describes how to load actual profile setpoints for clamp and ejector

operations.

After you read this chapter, you should have determined and entered the

following:

Clamp Close Profile (CPC)

Clamp Open Profile (OPC)

Ejector Profile (EPC)

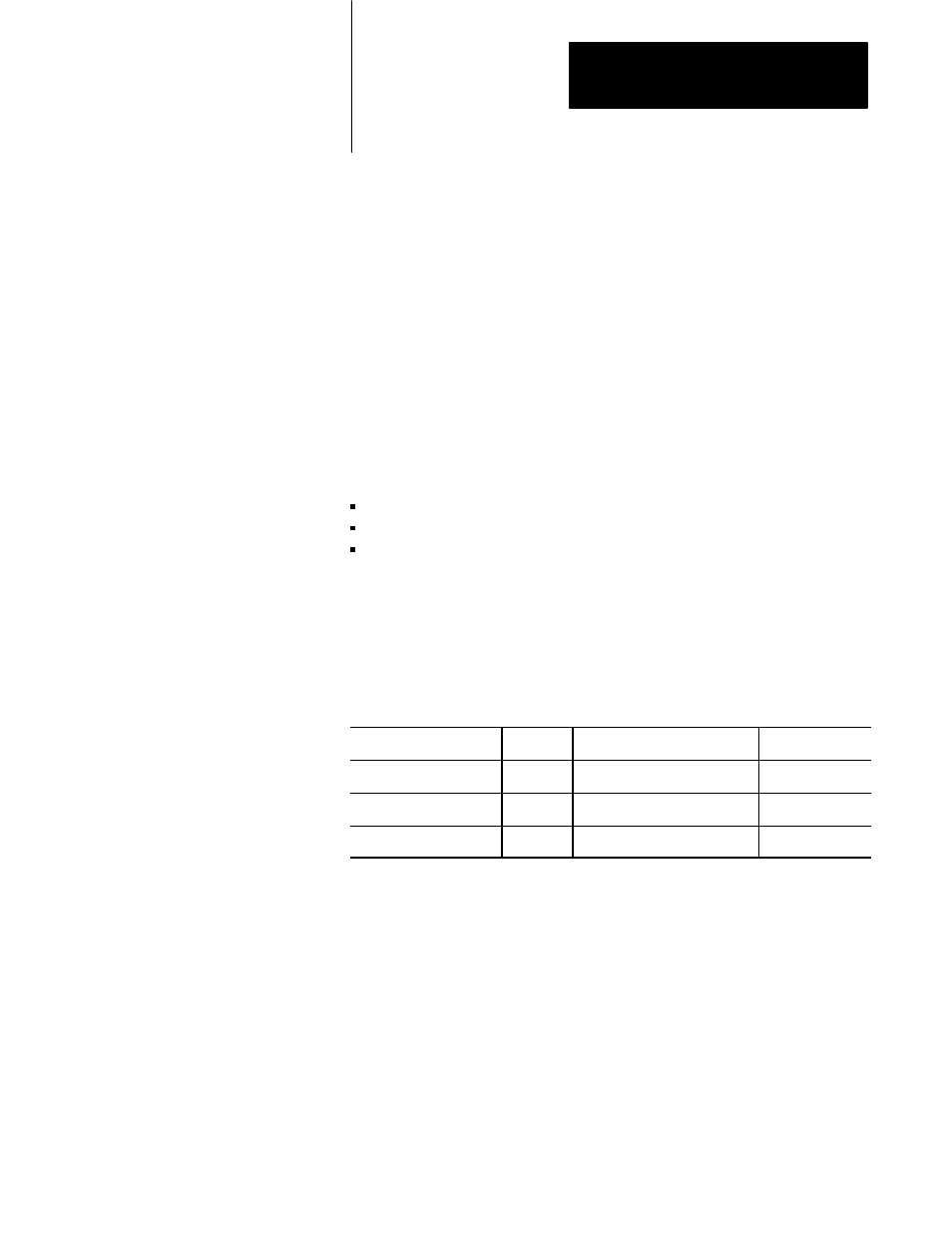

Command and Status Blocks Used

The following table contains a list of command blocks you are to configure

throughout the course of this chapter. You may reference these command

blocks in Sections 1 and 3 of the Plastic Molding Module Reference

Manual (pub. no. 1771-6.5.88).

Block:

Type:

Use in this Chapter:

ProĆSet 600 Files:

Clamp Close Profile (CPC) Command Enter Clamp Close Profile Values B37, N43

Clamp Open Profile (OPC) Command Enter Clamp Open Profile Values B37, N43

Ejector Profile (EPC)

Command Enter Ejector Profile Values

B39, N45

The following two pages contain worksheets for the Clamp Close Profile

(one worksheet for bit entries and one for word entries). The valve

spanning procedure in chapter 9 requires specific values in certain block

entries. We have already entered those values for you on your worksheets.

All parameters which required an entry based on your specific machine are

discussed briefly below the worksheet; and they are discussed in detail in

later chapters.

Chapter Objectives

Determine and Enter

Setpoints for the

Clamp Close Profile (CPC)