Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 71

Select Command and Status Bits

to Sequence Machine Operation

Chapter 6

6-4

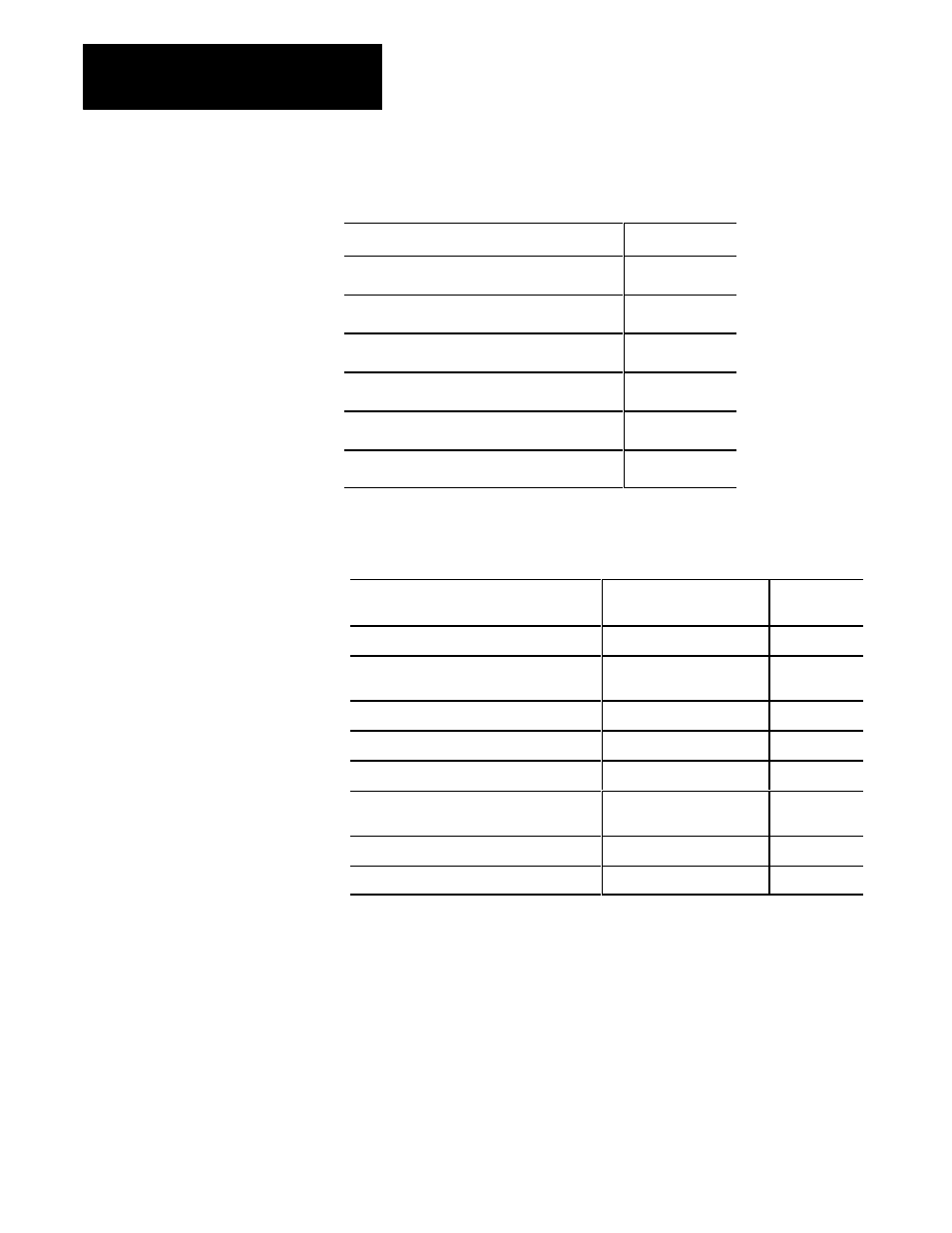

Table 6.E

Command Bits to Interrupt Clamp Movement Between Profiles

Bit Description:

QDC Block Addr.:

0 = start 2nd clamp close profile @ endĆof 1st

1 = stop and setĆoutput @ endĆof 1st

CPC03ĆB08

0 = start 3rd clamp close profile @ endĆof 2nd

1 = stop and setĆoutput @ end of 2nd

CPC03ĆB09

0 = start LP close profile @ endĆof 3rd

1 = stop and setĆoutput @ endĆof 3rd

CPC03ĆB10

0 = start 2nd clamp open profile @ endĆof 1st

1 = stop and setĆoutput @ endĆof 1st

OPC03ĆB08

0 = start 3rd clamp open profile @ endĆof 2nd

1 = stop and setĆoutput @ endĆof 2nd

OPC03ĆB09

0 = start clamp open slow profile @ endĆof 3rd

1 = stop and setĆoutput @ endĆof 3rd

OPC03ĆB10

Table 6.F

Miscellaneous Status Bits to Trigger New Clamp Events

Reason for Using:

Bit Description:

QDC Block

Addr.:

To drop pump adders, or shift solenoids

Clamp in moldĆprotect zone

SYS03ĆB00

To add pump adders, or shift solenoids for

tonnage build or lockĆup

Mold safe

SYS03ĆB01

To start inject cycle

Tonnage complete

SYS03ĆB02

To drop pump adders, or shift solenoids

Clamp in openĆslow zone

SYS03ĆB06

To idle the machine until starting next action

Mold fully open

SYS03ĆB07

To prevent starting next cycle when machine is

in auto mode

OpenĆdwell timer is timing

SYS03ĆB09

To start next cycle with machine in auto mode

Cycle complete

SYS03ĆB11

To reĆopen the clamp when the part is stuck

LP close watchdog timeĆout

SYS04ĆB03