Chapter 6 - program command-bit interaction, Chapter objectives, Assess your logic requirements – Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 68

Chapter

6

6-1

Select Command and Status Bits

to Sequence Machine Operation

In this chapter, we provide you with tables of command and status bits that

you use to write ladder logic to:

monitor input devices on your Ready Panel or operator station

step your QDC module through machine cycles

We suggest how to access your logic requirements and how to use bit

tables to write your machine’s sequential ladder logic based on those logic

requirements. This ladder logic depends on your machine’s hydraulic

configuration.

You must add your own ladder logic according to your machine’s

sequencing requirements.

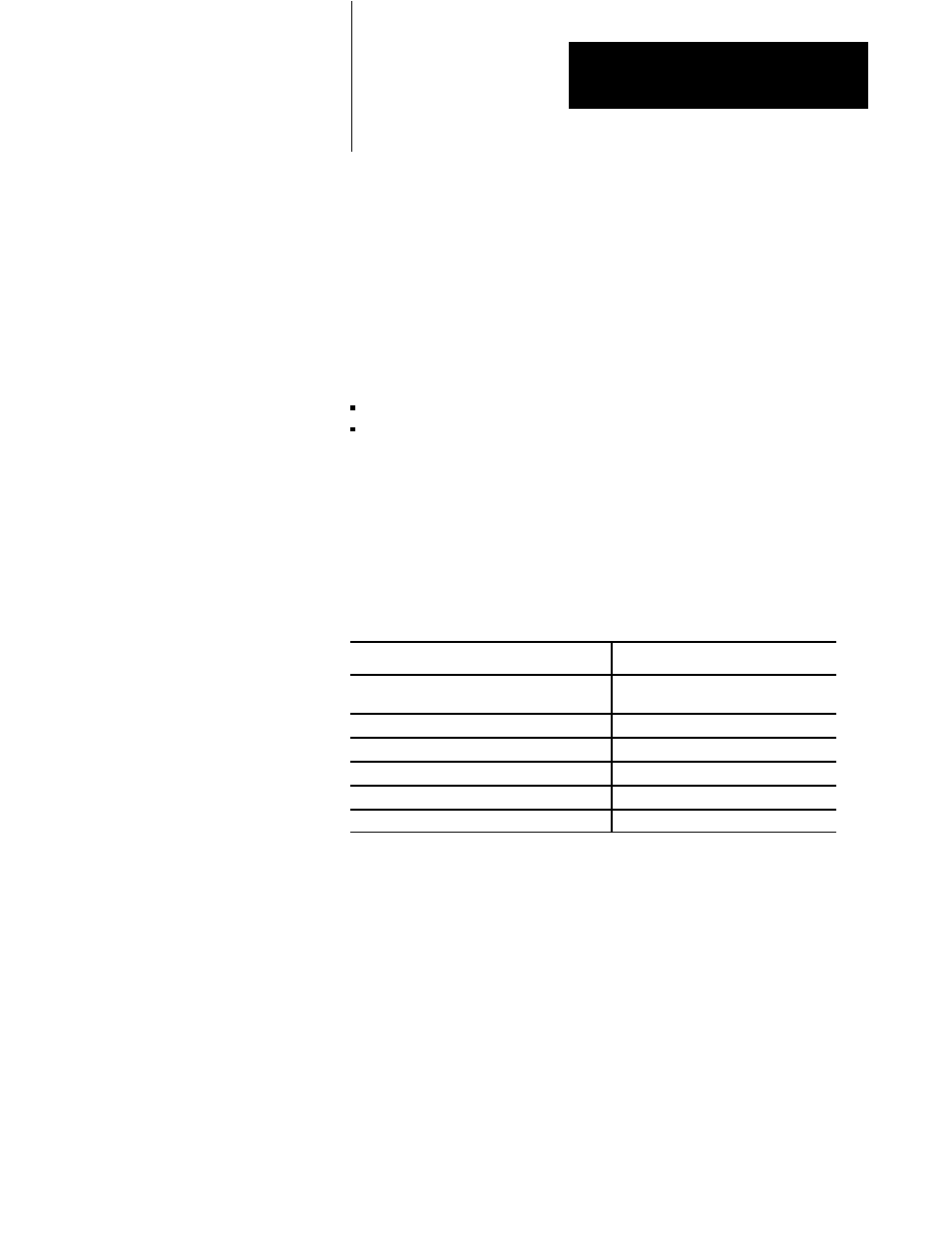

If you need to:

Then you must add:

Execute clampĆopen and clampĆclose phases

without interruption

no additional ladder logic

Execute the ejector profile without interruption

no additional ladder logic

Jog your machine

ladder logic (see chapter 5)

Stop at the end of a profile

ladder logic to start the next profile

Start a profile on command

ladder logic

Stop and notify at the end of the ejector stroke

ladder logic to continue the ejector profile

Important: We present information about command and status bits in this

chapter. For your convenience, a cross-reference between Pro-Set 600

software and QDC module bit addresses is listed in Table 6.I and Table 6.J

at the end of this chapter. If you need a more thorough description of these

bits, refer to section 3 of the Plastic Molding Module Reference Manual

(pub. no. 1771-6.5.88).

Chapter Objectives

Assess Your

Logic Requirements