Span your clamp and ejector valves chapter 9, Command and status blocks used – Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 138

Span Your Clamp and Ejector Valves

Chapter 9

9-2

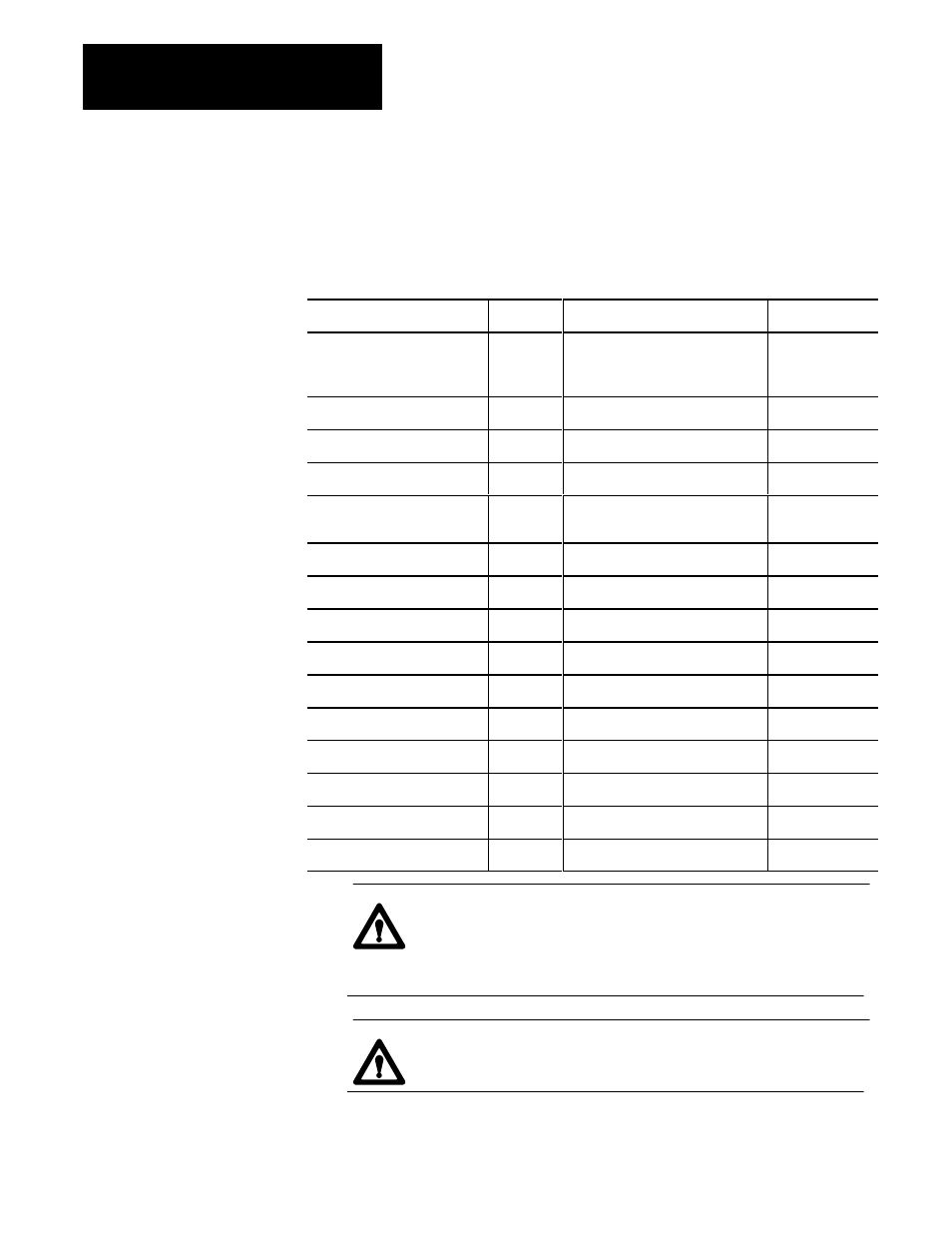

Command and Status Blocks Used

The following table contains a list of command blocks you are to configure

throughout the course of this chapter. You may reference these command

blocks in sections 1 and 3 of the Plastic Molding Module Reference

Manual (pub. no. 1771-6.5.88).

Block:

Type:

Used in this Chapter to:

ProĆSet 600 Files:

System (SYS)

Status

View Programming Errors

View Clamp Position

View Ejector Position

B35, N41

Clamp Close Profile (CPC)

Command

Enter Clamp Close Profile Values

B37, N43

Clamp Open Profile (OPC)

Command

Enter Clamp Open Profile Values

B37, N43

Ejector Profile (EPC)

Command

Enter Ejector Profile Values

B39, N45

Dynamic Command Block

(DYC)

Command

Initiate Profile Execution

B37, N43

First Clamp Close (FCC)

Command

Enter First Clamp Close Values

B37, N43

Second Clamp Close (SCC)

Command

Enter Second Clamp Close Values

B37, N43

Third Clamp Close (TCC)

Command

Enter Third Clamp Close Values

B37, N43

Clamp Low Press Close (LPC)

Command

Enter Clamp Low Press Close Values B37, N43

First Clamp Open (FOC)

Command

Enter First Clamp Open Values

B37, N43

Second Clamp Open (SOC)

Command

Enter Second Clamp Open Values

B37, N43

Third Clamp Open (TOC)

Command

Enter Third Clamp Open Values

B37, N43

Clamp Open Slow (OSC)

Command

Enter Clamp Open Slow Values

B37, N43

Ejector Advance (EAC)

Command

Enter Ejector Advance Values

B39, N45

Ejector Retract (ERC)

Command

Enter Ejector Retract Values

B39, N45

ATTENTION: As with any machine start-up, make sure a test

mold is installed in the machine. Programming errors,

configuration errors, or hydraulic problems could lead to

machine damage or injury to personnel.

ATTENTION: Make sure all machine guards and shields are in

place before proceeding.