Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 36

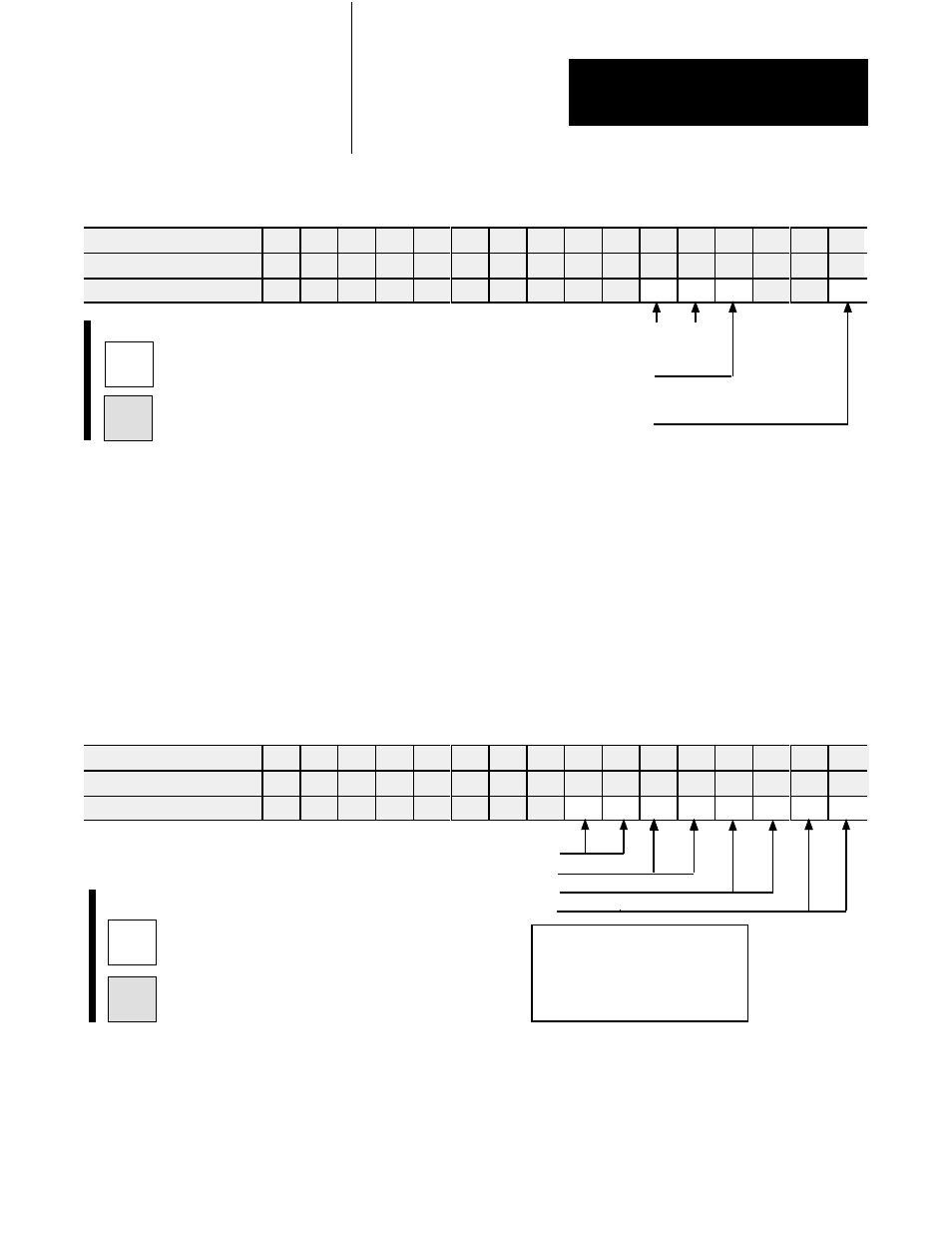

Select System Operation with bits 05 and 04

Clamp and Eject 1 0

Select SingleĆunit Operation with bit 03 = 1

(0 generates a programming error)

Select English = 0 or

metric = 1 with bit 00

Code:

Your value

Required initial value

loaded by ProĆSet 600

0 or 1

Select Input 1 (Ejector Position) Range with bits 01, 00

Select Input 2 (Ejector Pressure) Range with bits 03, 02

Select Input 3 (Clamp Position) Range with bits 05, 04

Select Input 4 (Clamp Pressure) Range with bits 07, 06

Input Range

0 - 10V dc 0 0

1 - 5V dc 0 1

4 - 20 mA 1 0

Not connected 1 1

Code:

Your value

Required initial value

loaded by ProĆSet 600

0 or 1

Configure the QDC Module's

Inputs and Outputs

Chapter 3

3-3

Worksheet 3ĆA

Selecting Module Parameters

Control Word MCC02ĆBxx

15

14 13 12

11

10

09 08 07 06 05 04 03 02 01 00

ProĆSet 600 Addr. B35/bit

543 542 541 540 539 538 537 536 535 534 533 532 531 530 529 528

Value

0

0

0

0

0

0

0

0

0

0

1

0

1

0

0

Example: If you select Clamp and Eject operation with English units:

MCC02 = 00000000 00101000

Selecting I/O Ranges for your Sensors

Next, configure the QDC module’s I/O ranges to match the machine

sensors and valves. Refer to Worksheet 2-A from chapter 2 which you

filled out when setting the QDC module’s jumpers. Apply this information

to Worksheet 3-B for input ranges and Worksheet 3-C for output ranges.

Worksheet 3ĆB

Selecting Input Ranges for your Sensors

Control Word MCC03ĆBxx

15

14 13 12 11

10

09 08 07 06 05 04 03 02 01 00

ProĆSet 600 Addr. B35/bit

559 558 557 556 555 554 553 552 551 550 549 548 547 546 545 544

Value

1

1

1

1

1

1

1

1

Example: If you select an input range of 4-20mA for all four inputs,

MCC03 = 11111111 10101010.

Important: Software input/output selections must match the jumper

settings for each respective input/output.