Install the qdc module chapter 2 – Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 33

Install the QDC Module

Chapter 2

2-12

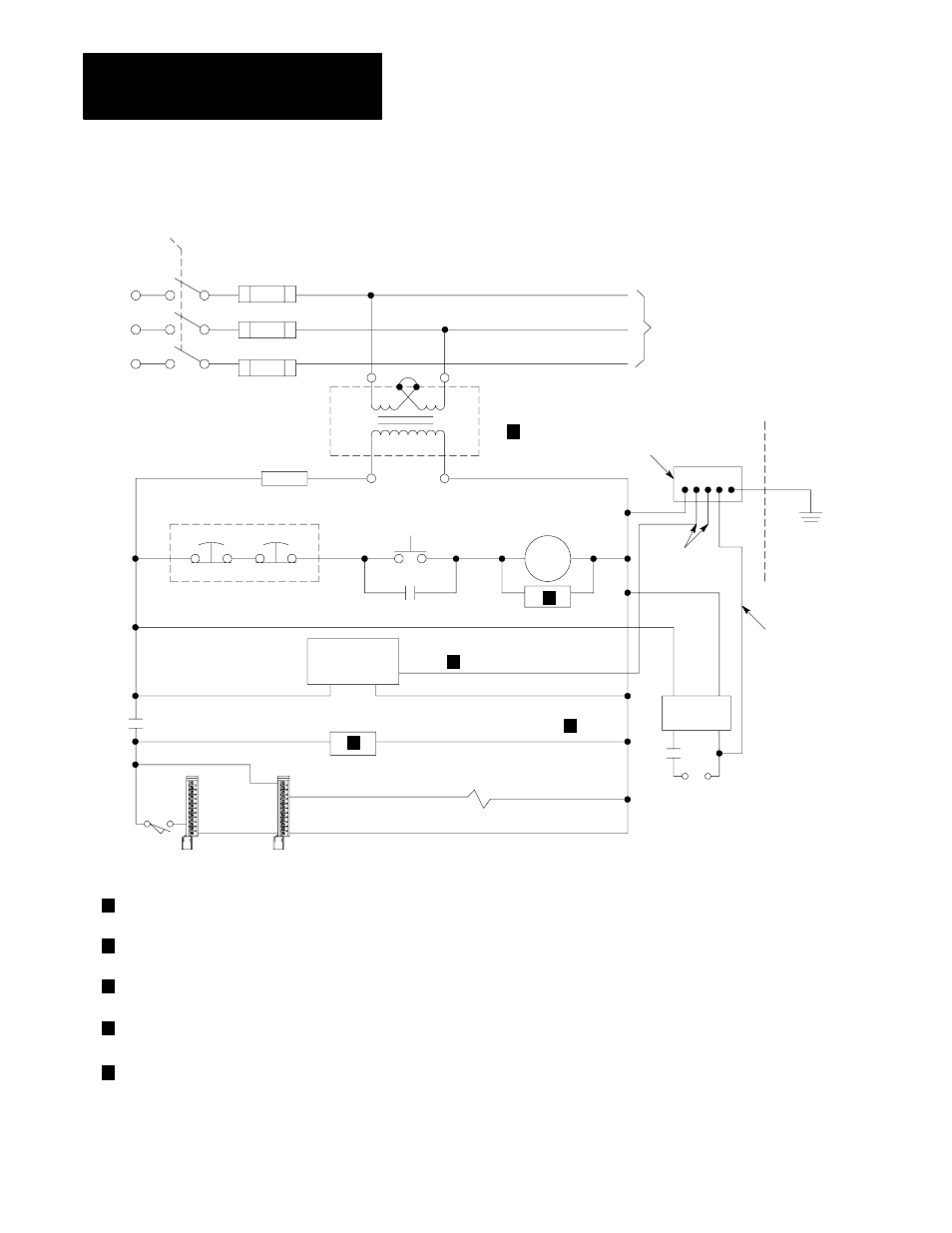

Figure 2.6

Typical PLC Power Distribution with Interlocks

Incoming

AC

L1

L2

L3

1FU

2FU

3FU

H

FUSE

Disconnect

To Motor

Starters

L1

L2

L3

H

Back-Panel

Ground Bus

Enclosure

Wall

Grounding Electrode

Conductor to

Grounding Electrode

System

Connect

When

Applicable

Equipment

Grounding

Conductors

User DC

Supply

CRM

To DC I/O

Devices

+

–

Output

Module

Wiring

Arm

Input

Module

Wiring

Arm

Output

Device

Input

Device

I/O Chassis

10907ĆI

Power Supply

L

N

1

GND

CRM

Start

Use any number

of E-Stop switches

in Series

CRM

CRM

1

4

H

3

H

2

Step-down

Transformer

X

1

X

2

To minimize EMI generation, you should connect a suppression network: for 120V AC, use Allen-Bradley

cat. no. 700-N24; for 220/240V AC, use cat. no. 599-KA04.

To minimize EMI generation, you should connect a suppression network: for 120V AC, use Allen-Bradley

cat. no. 599-K04; for 220/240V AC, use cat. no. 599-KA04.

For a power supply with a groundable chassis, this represents connection to the chassis only. For a power supply

without a groundable chassis, this represents connection to both the chassis and the GND terminal.

In many applications, a second transformer provides power to the input circuits and power supplies for isolation from the

output circuits.

1

2

3

4

1

2

3

4

** See WARNING for Interlock Wiring Instructions **

5

5

Reference the current NEC code and ANSI B151.1 for additional wiring guidelines.

To minimize EMI generation, suppression networks should be connected across coils of electromagnetic devices.

•

•