Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 179

Tune Your Machine

Chapter 10

10-6

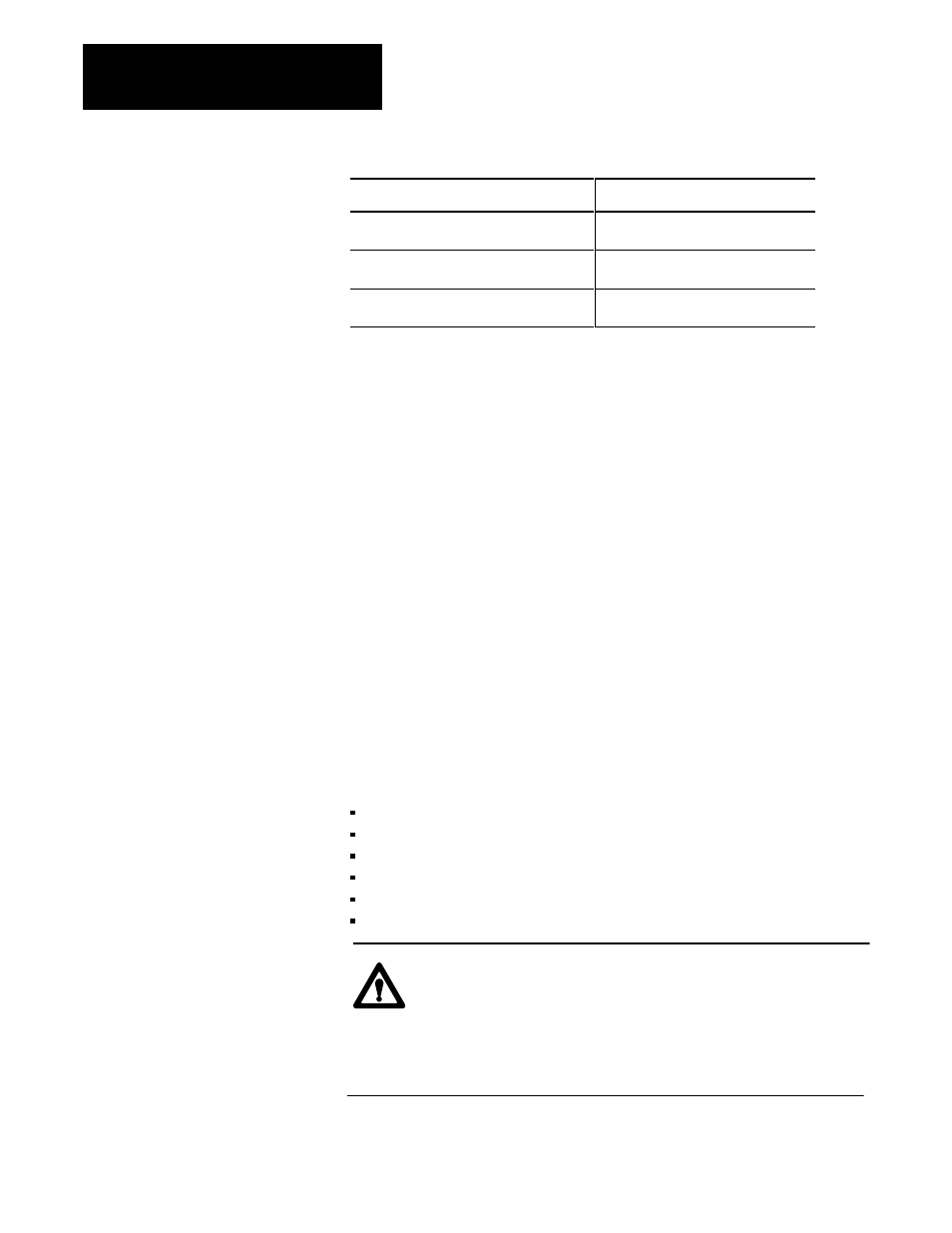

If:

Then:

Observed actuals are consistently well below

profile setpoints

Increase proportional term(s)

Observed actuals are consistently well above

profile setpoints

Decrease proportional term(s)

Excessive hammering and vibration is

observed in the cylinder's hydraulic lines

Decrease proportional term(s)

Important: Each change to a tuning constant requires you to download

your changes to the QDC module. Refer to the Download Procedure

outlined in chapter 4.

Repeat the profile(s) cycles after each change to the proportional term(s)

until observed actuals are close to setpoints without hammering and

vibration in the controlling cylinder’s hydraulic lines.

Without modifying the proportional term(s) determined by the above

procedure, slowly begin increasing the appropriate integral term(s) while

running machine cycles until the observed profile pressure actuals are

overshooting the profile setpoints. Now decrease the integral term(s) until

the overshoot is no longer observed.

If you cannot make your observed pressures actuals match your entered

setpoints, verify your Unselected Valve Set-output Values are correct for

your application (Refer to chapter 7 and the discussion later in this

chapter).

Tune Pressure Loops with an Oscilloscope

Before you begin tuning your pressure loops, confirm the following:

Pressure vs. position is selected

Closed-loop is selected

ERC is disabled

ERC values have been reset

Ramping is disabled

All setpoint changes have been download to the QDC module

ATTENTION: Prior to running clamp profiles, refer to chapter

8 to verify that the appropriate Low Pressure Close Zone

Overrun or Open Slow Zone Overrun setpoints and bit

selections are entered properly and downloaded to the QDC

module. Do this to minimize the possibility of mold or machine

damage.