Rockwell Automation 1771-QDC, D17716.5.87(Passport) CLAMP AND EJECT MODE User Manual

Page 158

Span Your Clamp and Ejector Valves

Chapter 9

9-22

If the observed pressure OPS13 is still not representative of the setpoint

(within 20% of OPC13), your pressure valve is not linear over the desired

range of operation.

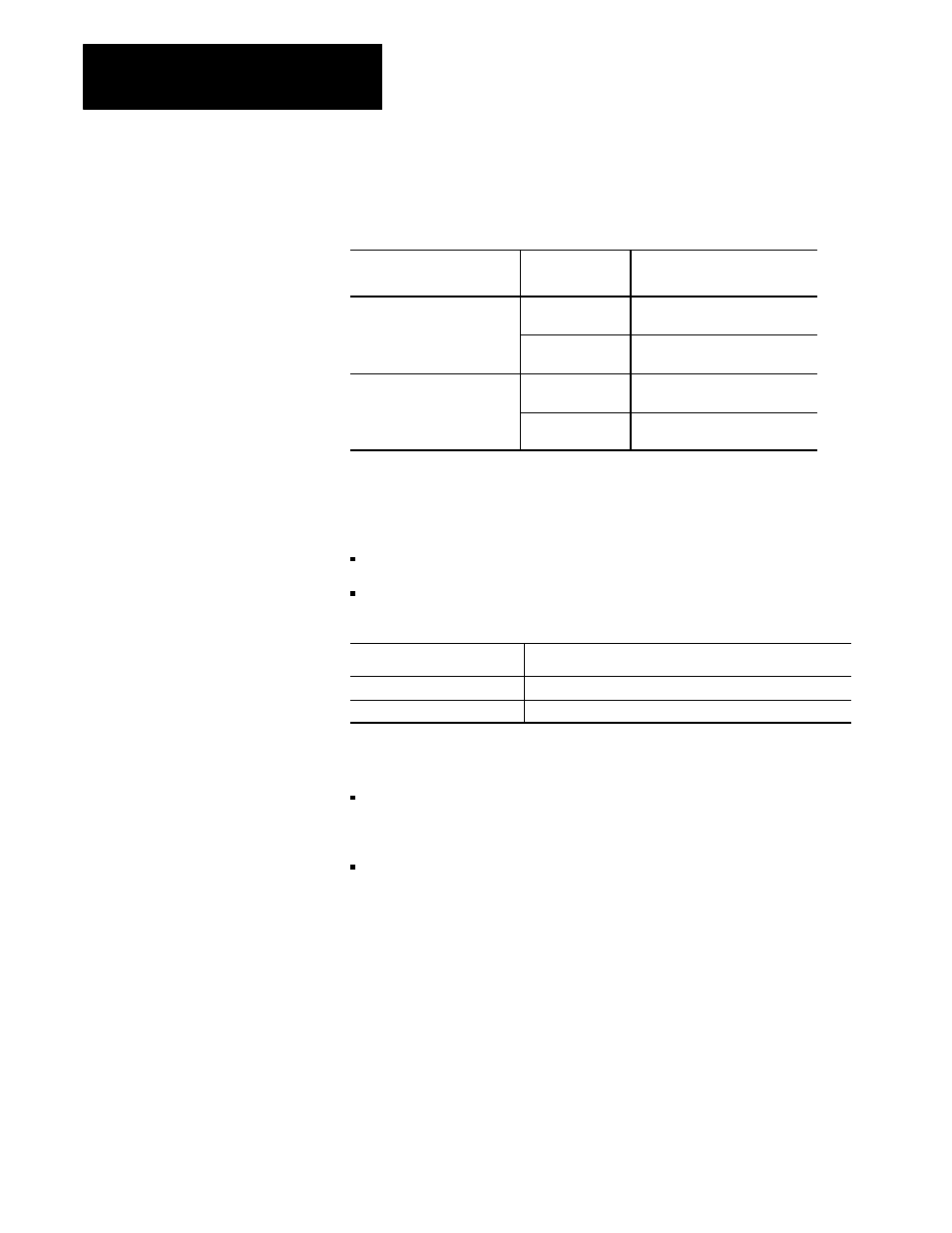

If:

And Your

Selected Valve is:

Then:

OPS13 was less than OPC13

Direct Acting

Increase FOC44, SOC44,

TOC44, and OSC44 by 5%

Reverse Acting

Decrease FOC44, SOC44,

TOC44, and OSC44 by 5%

OPS13 was more than

OPC13

Direct Acting

Decrease FOC44, SOC44,

TOC44, and OSC44 by 5%

Reverse Acting

Increase FOC44, SOC44,

TOC44, and OSC44 by 5%

Repeat steps 2 through 5 as necessary.

What You Have Accomplished

The valve spanning procedure you just completed has:

defined the range of pressure available during any clamp open profile

informed the QDC module of the signal level needed to drive the

selected clamp pressure valve(s) for any requested open-loop pressure:

% of Signal Level Entered In: Drives the Selected Valve to Produce:

FOC43,SOC43,TOC43,OSC43 Pressure (Usually 0) in FOC41, SOC41, TOC41, and OSC41

FOC44,SOC44,TOC44,OSC44 Pressure in FOC42, SOC42, TOC42, and OSC42

Now, for all open-loop pressure-controlled clamp open profiles, the QDC

module:

drives the selected clamp pressure valve between the signal limits

imposed by FOC43 and FOC44, or SOC43 and SOC44, or TOC43 and

TOC44, or OSC43 and OSC44

assumes a linear relationship between clamp pressure and the signal

outputs

Set Pressure Alarm Setpoints

After spanning your Clamp Open pressure valve(s), set your Clamp Open

maximum pressure alarms (FOC57, SOC57, TOC57, OSC57) equal to

values you feel should not occur during the respective Clamp Open

profiles. Make sure none of these values are greater than their respective

Clamp Open Maximum Pressure Control Limits (FOC42, SOC42, TOC42,

OSC42). Entering a value of 0 disables this alarm.

Download changes to the QDC module. If necessary, refer to the

Download Procedure in chapter 4.