6 automation tab, Automation tab, Automation – Red Lion IndustrialPr 6000 Router User Manual

Page 114

Software User Guide

114

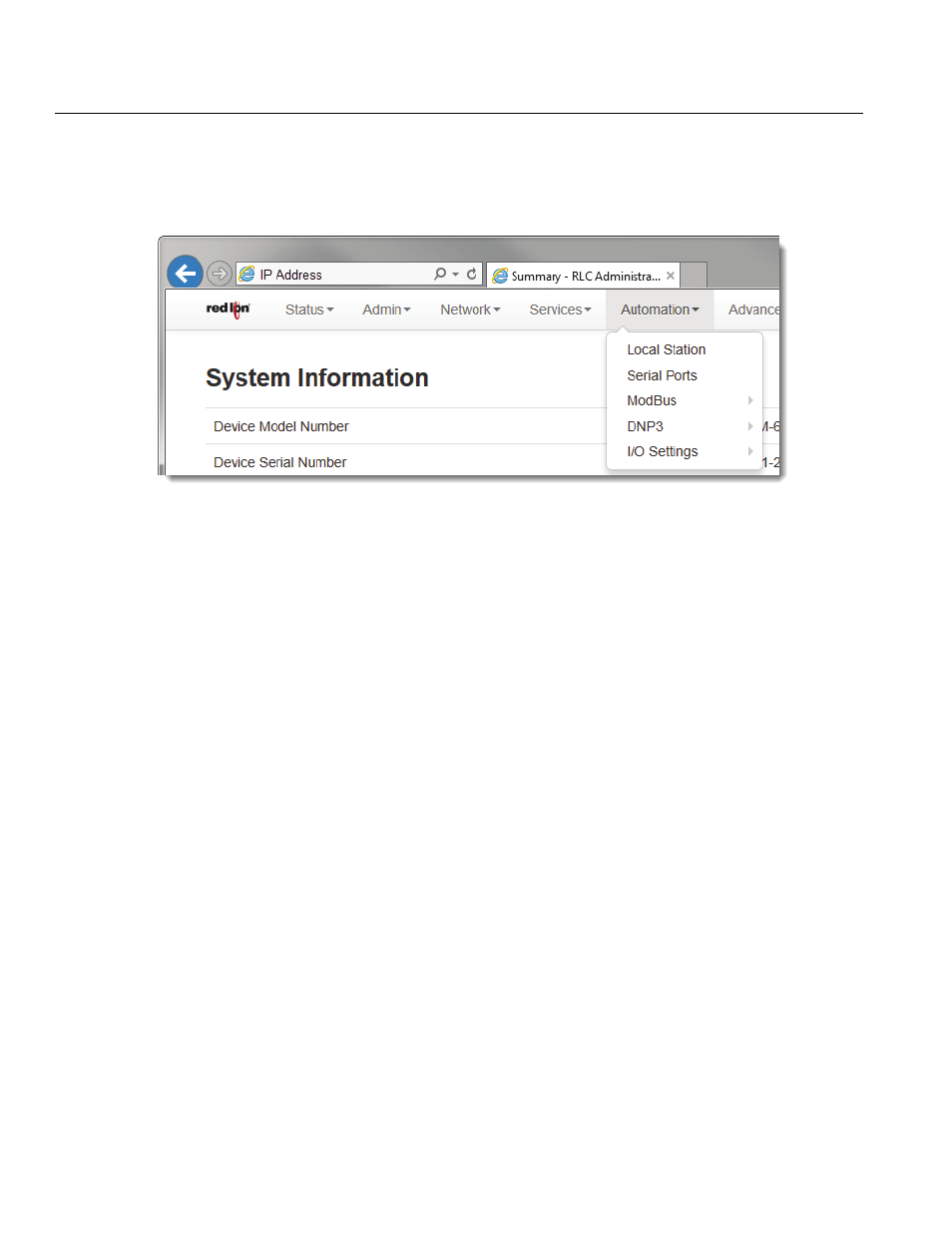

Automation Tab

3.6

Automation Tab

The Automation menu contains all aspects of managing your Modbus and DNP3 based I/O.

Note: If prompted for an Unlock Key, contact Red Lion Support at

or 1‐877‐432‐9908

This option is only supported if the IndustrialPro router has been upgraded from an SN prefix to IndustrialPro RAM and for

the RAM 9000 series. The IndustrialPro RAM firmware MODBUS application allows it to act as a MODBUS Master acting as

an I/O concentrator for MODBUS/DNP3 devices. I/O for these devices can be read or written using MODBUS/DNP3 I/O

transfers with the IndustrialPro acting as a MODBUS/DNP3 master. I/O data is stored in a local I/O database.

The IndustrialPro RAM and RAM 9000 series will support:

•

I/O transfers using MODBUS/DNP3

•

Slave Station Status

•

Forwarding of MODBUS/DNP3 messages

•

Developing of third party applications using our SDK based on ELDK4.2 and the SIXNET IODB API.

Additionally, the IndustrialPro and RAM 9000 series will act as a MODBUS slave. This allows MODBUS masters to request

or update I/O points in the I/O database.

Modbus Configuration:

User interfaces will be provided to configure I/O transfers, the MODBUS forwarding table and serial interfaces. MODBUS

configuration data will be stored in an XML based file named modbus.xml. This file will contain the following sections:

•

serials: xml section to define the parameters used for serial ports for both MODBUS and DNP3.

•

localStation: xml section to define the local station number and name for both MODBUS and DNP3.

•

remoteStations: defines remote stations and the I/O transfers associated with them.

•

regAllocation: defines the number of registers for each I/O type.

•

forwards: defines the list of remote stations to forward MODBUS requests.

There are two (2) methods to configure these sections.