Red Lion DLC User Manual

Model dlc - dual loop controller, General description, Safety summary

1

MODULAR BUILDING BLOCK FOR MULTI-ZONE PROCESS CONTROL

TWO INDEPENDENT PID CONTROL LOOPS

PID CONTROL WITH REDUCED OVERSHOOT

UNIVERSAL INPUTS ACCEPT TC, RTD, 0-10 V and 0/4-20 mA SIGNALS

TWO DC ANALOG OUTPUTS (OPTIONAL)

WINDOWS

®

CONFIGURATION SOFTWARE

RS485 MODBUS™ PROTOCOL

CHANNEL B CAN BE ASSIGNED AS A SECOND ANALOG INPUT TO

CHANNEL A FOR REMOTE SETPOINT OPERATION

SETPOINT CONTROLLER OPTION FOR TIME VS. TEMP./PROCESS

(RAMP/SOAK) AND SPECIAL BATCH/RECIPE APPLICATIONS

SQUARE ROOT EXTRACTION FOR FLOW SENSOR APPLICATIONS

GENERAL DESCRIPTION

The Model DLC, Dual Loop Controller, is a full featured, DIN rail mounted,

dual input PID controller. The DLC is designed as a modular building block for

multi-zone process control applications. The controller has two independent

“A” & “B” input channels. Each channel’s input can be configured to accept a

wide range of thermocouple, RTD, 0-10 V, 0/4-20 mA, or resistive signals. Each

channel can also be configured to extract the square root of the input in both

process voltage or process current modes for applications such as flow

measurement using a differential flow sensor.

Channel B can be assigned as a Remote Setpoint for Channel A. The two time-

proportioning or DC Analog outputs can be programmed to control two

independent processes. The two alarms per channel can be configured for various

alarm modes, or provide a secondary control output for heat/cool applications.

The control and alarm outputs are N channel open drain MOSFETs capable

of switching up to 1 Amp DC. For applications requiring larger loads or A/C

loads, several DIN rail mount relays are available.

The controller operates in the PID Control Mode for both heating and

cooling, with on-demand auto-tune, that establishes the tuning constants. The

PID tuning constants may be fine-tuned through the serial interface. The

controller employs a unique overshoot suppression feature, which allows the

quickest response without excessive overshoot. The controller can be transferred

to operate in the Manual Mode, providing the operator with direct control of the

output, or the On/Off Control Mode with adjustable hysteresis.

The controller’s high density packaging and DIN rail mounting saves time

and panel space. The controller snaps easily onto standard top hat (T) profile

DIN rails.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use the controller to directly command motors, valves, or other

actuators not equipped with safeguards. To do so can be potentially harmful to

persons or equipment in the event of a fault to the controller. An independent

and redundant temperature limit indicator with alarm outputs is strongly

recommended.

ALARMS

The DLC’s two solid-state alarms can be configured independently for

absolute high or low acting with balanced or unbalanced hysteresis. They can

also be configured for deviation and band alarm. In these modes, the alarm

trigger values track the setpoint value. Adjustable alarm trip delays can be used

for delaying output response. The alarms can be programmed for Automatic or

Latching operation. Latched alarms must be reset with a serial command. A

standby feature suppresses the alarm during power-up until the temperature

stabilizes outside the alarm region. The outputs can also be manually controlled

with Modbus register or coil commands.

SETPOINT CONTROLLER OPTION

The Setpoint Controller option is suitable for time vs. temperature/process

control applications. The controller allows a profile of up to 20 ramp/soak

segments. Profile conformity is assured by using the Error Band Mode and

Error Band parameter. The Profile Cycle Count allows the profile to run

continuously or a fixed number of cycles. Power-on options automatically stop,

abort, start, resume, or pause a running profile.

ORDERING INFORMATION

MODEL NO.

DESCRIPTION

PART NUMBERS

DLC

Dual Loop Controller

DLC00001

Dual Loop Controller w/ 2 Analog Outputs

DLC01001

Dual Setpoint Controller w/ 2 Analog Outputs

DLC11001

SF

PC Configuration Software for Windows

SFDLC

CBPRO

Programming Interface Cable

CBPRO007

CBJ

Cable RJ11 to RJ11 (6 inch jumper)

CBJ11BD5

DRR

RJ11 to Terminal Adapter

DRRJ11T6

P89

Paradigm to RJ11 Cable

P893805Z

See our RSRLYB, RLY6, and RLY7 literature for details on DIN rail

mountable relays.

MODEL DLC - DUAL LOOP CONTROLLER

Bulletin No. DLC-H

Drawing No. LP0495

Released 05/12

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

UL Recognized Component,

File #E156876

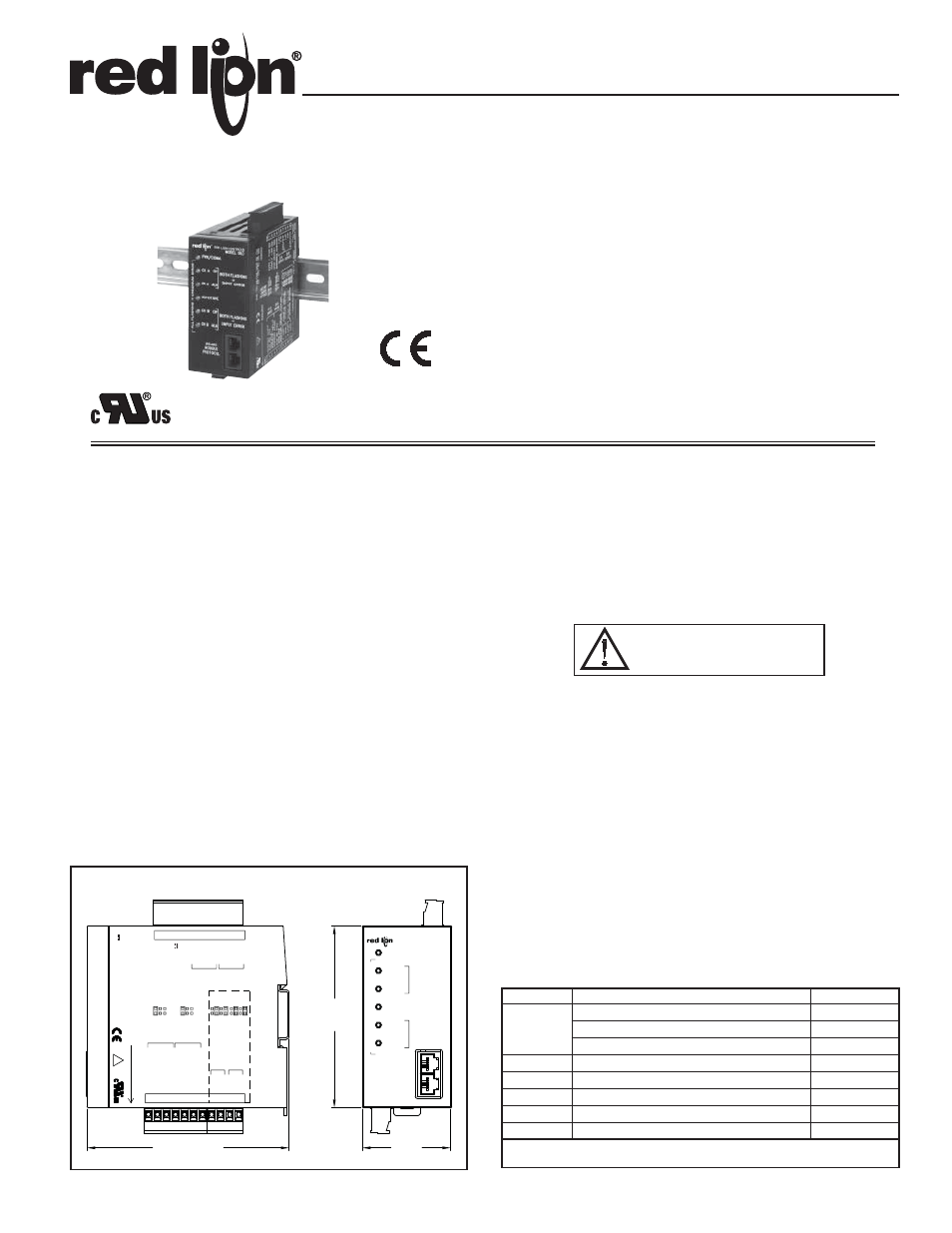

OPTIONAL

BOTH FLASHING

ALL FLASHING = CHECKSUM ERROR

0-10V, 0-20mA

ANALOG OUTPUT 1

0-10V, 0-20mA

ANALOG OUTPUT 2

JUMPERS

INPUT ERROR

RS485

MODBUS

PROTOCOL

CH B ALM

=

6

0-10V, 0-20mA

0-10V, 0-20mA

TC+ OR RTD

INPUT COMMON

TC+ OR RTD

INPUT COMMON

RTD EXC.

TBB

1

2

RTD EXC.

4

3

5

INPUTS

CH B

CH A

INPUTS

DEFAULT SERIAL SETTING

OUT +

OUT -

7

8

9

OUT +

OUT -

11

10

PWR/COMM.

INPUT ERROR

BOTH FLASHING

CH A ALM

AUTOTUNE

CH B OP

CH A OP

=

SETTINGS

FACTORY

JUMPER

MODEL DLC

AL2/OP2

AL2/OP2

OUTPUT COMMON

OUTPUTS

10V

20mA

RTD

10V

RTD

20mA

DC- / (AC)

DC+ / (AC)

+24VDC OUT

I1-

I1+

V1+

V1-

V2-

V2+

I2+

I2-

OUTPUTS

CH A

CH B

5

OP1

TBA

1

ต

3

2

ต

4

6

AL1

7

8

OP1

10

9

AL1

YORK, PA.

MADE IN U.S.A.

4.06 (103)

(102)

1.97

4.02

(50)

RED LION CONTROLS

AC 24V ±10%, 50/60 Hz, 15VA

DC 18-36V, 13W

POWER: (FULL LOAD)

ต

!

MODEL DLC

RED LION CONTROLS

DIMENSIONS In inches (mm)

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.